5-48

5

TROUBLESHOOTING

CONTROL VALVE

“4. Disassembly and assembly, Control valve”

The problems are listed individually in the table below, but in reality, many problems have multiple causes. Therefore, try to

check and eliminate each possible cause one at a time.

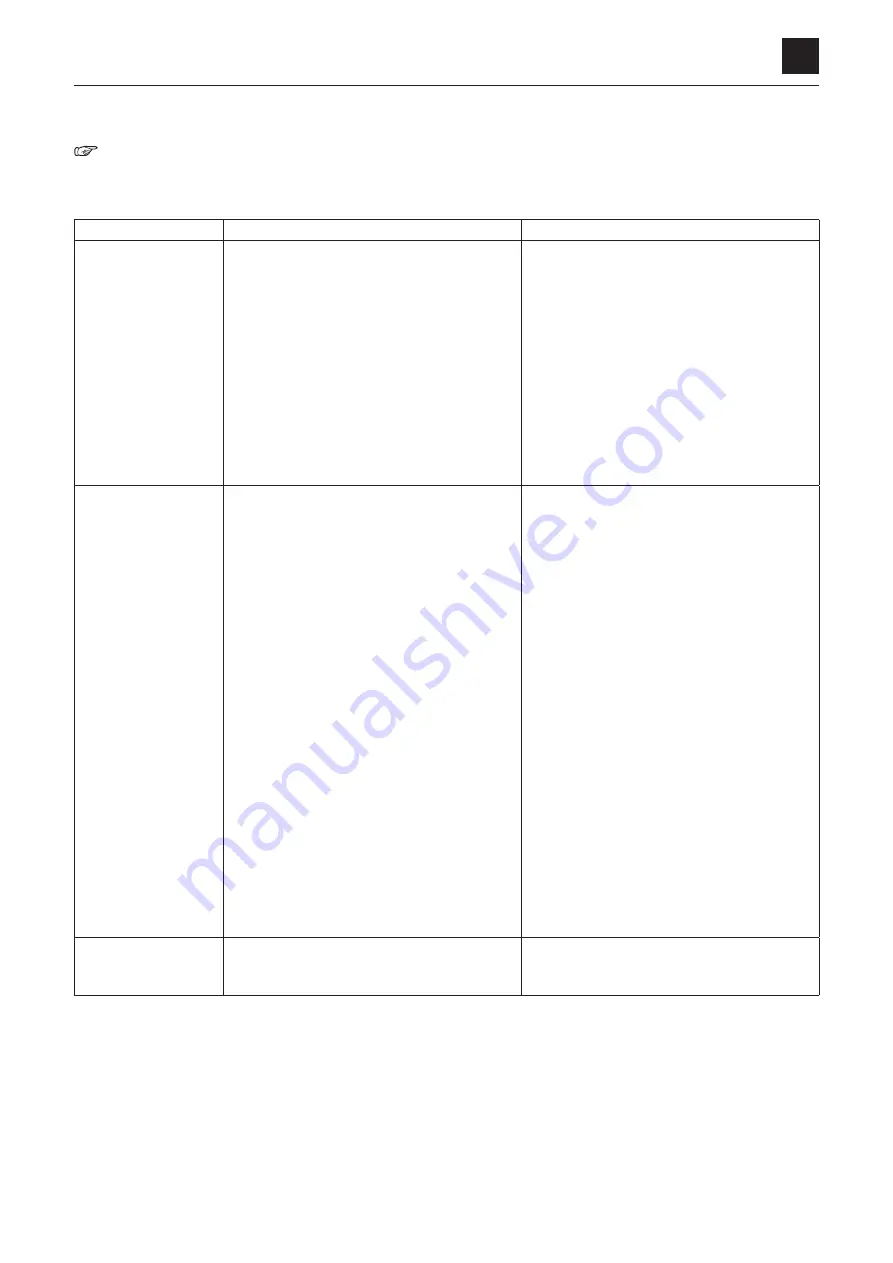

Symptoms

Major causes

Remedies

Oil leak from the spool

seal

• Flaw is on the sealing part or the seal lip is

worn out due to prolonged use

• Flaw (e.g., dents or scratches) on the sliding

part of the seal is caused by an external fac-

tor

• The lid that is pushing the sealing parts in

place is installed improperly (lid is distorted)

• Old paint remains on the seal sliding part of

the spool

• Tank pressure becomes too high for the per-

formance of the sealing material

• Replace with a new one.

• Repair or replace the spool.

• Correct the lid, and determine the partial

wear degree of the seal.

• Remove it by using thinner or mechanical

force.

When removing, take care not to damage the

spool surface or the seal lip.

• Remove the cause of the flow resistance.

Sliding part of the

spool is not smooth

• Foreign matter is caught in the sliding part of

the spool

• Oil film between the spool and the body be-

comes too thin due to the increased oil tem-

perature

• Lubrication is disabled due to deteriorated

oil

• Spool is worn out because of prolonged use

or of the unbalanced force applied

• Spool is bent by the external force

• Whole Valve is distorted due to the distortion

of the installation surface

• Valve is operated with the pressure or the

flow rate of out-of-spec

• Fixing bolts are over-tightened

• Oil stays in the lid (spring or detent) opposite

to the spool operation

• Overhaul and repair or replace.

• Try to decrease the oil temperature. If the re-

lief valve is started often, find the cause and

correct it.

• Oil should be replaced. The circuit also

should be overhauled in some cases.

• Replace the spool and the valve block as-

sembly.

• Check for the straightness of the spool, and

repair or replace.

• Check the distortion, independent of the

installation surface (loosening the bolts will

help).

• For pressure, measure it with a pressure

gauge. For flow rate, determine it by finding

out the movement speed and capacity of the

actuator.

• Check if the fixing bolts are tightened with the

specified torque. If not, tighten them again

with the specified torque.

• Oil may come out from the lid, if it is leaking

in the seal of the spool. If that is the case,

replace the seal.

When the actuator is

being raised, it drops

once

• Foreign matter is caught in the seat on the

load check valve, or the seat is damaged by

large foreign matter

• Disassemble the valve and overhaul or re-

place the faulty part(s).

CONTROL VALVE

Summary of Contents for TB 250

Page 1: ......

Page 3: ...1 1 SAFETY 1 Safety alert symbol 1 2 Safety precautions 1 3 Cautions when working 1 9...

Page 36: ...2 24 2 TIGHTENING TORQUE SERVICE DATA...

Page 38: ...2 26 2 HYDRAULIC CIRCUIT DIAGRAM SERVICE DATA Equipped with options 2 2...

Page 39: ...2 27 2 HYDRAULIC CIRCUIT DIAGRAM SERVICE DATA Equipped with angle blade and blade oat 1 2...

Page 40: ...2 28 2 HYDRAULIC CIRCUIT DIAGRAM SERVICE DATA Equipped with angle blade and blade oat 2 2...

Page 41: ...2 29 2 HYDRAULIC CIRCUIT DIAGRAM SERVICE DATA Equipped with high ow option 1 2...

Page 42: ...2 30 2 HYDRAULIC CIRCUIT DIAGRAM SERVICE DATA Equipped with high ow option 2 2...

Page 49: ......

Page 59: ...2 46 2 WIRE HARNESS WIRING DIAGRAM SERVICE DATA...

Page 60: ...2 47 2 WIRE HARNESS WIRING DIAGRAM SERVICE DATA...

Page 61: ...2 48 2 WIRE HARNESS WIRING DIAGRAM SERVICE DATA...

Page 62: ...2 49 2 WIRE HARNESS WIRING DIAGRAM SERVICE DATA...

Page 63: ...2 50 2 WIRE HARNESS WIRING DIAGRAM SERVICE DATA...

Page 64: ...2 51 2 WIRE HARNESS WIRING DIAGRAM SERVICE DATA...

Page 65: ...2 52 2 WIRE HARNESS WIRING DIAGRAM SERVICE DATA...

Page 66: ...2 53 2 WIRE HARNESS WIRING DIAGRAM SERVICE DATA...

Page 67: ...2 54 2 WIRE HARNESS WIRING DIAGRAM SERVICE DATA...

Page 68: ...2 55 2 WIRE HARNESS WIRING DIAGRAM SERVICE DATA...

Page 69: ...2 56 2 WIRE HARNESS WIRING DIAGRAM SERVICE DATA...

Page 70: ...2 57 2 WIRE HARNESS WIRING DIAGRAM SERVICE DATA...

Page 71: ...2 58 2 WIRE HARNESS WIRING DIAGRAM SERVICE DATA...

Page 72: ...2 59 2 WIRE HARNESS WIRING DIAGRAM SERVICE DATA...

Page 73: ...2 60 2 WIRE HARNESS WIRING DIAGRAM SERVICE DATA NAME STANDARD NO...

Page 74: ...2 61 2 WIRE HARNESS WIRING DIAGRAM SERVICE DATA...

Page 75: ...2 62 2 WIRE HARNESS WIRING DIAGRAM SERVICE DATA...

Page 76: ...2 63 2 WIRE HARNESS WIRING DIAGRAM SERVICE DATA...

Page 77: ...2 64 2 WIRE HARNESS WIRING DIAGRAM SERVICE DATA...

Page 78: ...2 65 2 WIRE HARNESS WIRING DIAGRAM SERVICE DATA...

Page 79: ...2 66 2 WIRE HARNESS WIRING DIAGRAM SERVICE DATA...

Page 80: ...2 67 2 WIRE HARNESS WIRING DIAGRAM SERVICE DATA...

Page 81: ...2 68 2 WIRE HARNESS WIRING DIAGRAM SERVICE DATA...

Page 92: ...3 11 3 CONTROL VALVE FUNCTION...

Page 108: ...4 3 4 SERVICE STANDARDS DISASSEMBLY AND ASSEMBLY Clearance for pin and bushing...

Page 352: ...ENGINE 6 Machine model Mounted engine TB250 4TNV88...