D200-100-00

1

I56-3888-005

CONTENTS

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

The FAAST LT Functional State Diagram . . . . . . . . . . . . . . . . . 1

Password Procedure (to enter Maintenance Mode)

2

An Introduction to PipeIQ™ . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Using PipeIQ™ to Configure and Monitor FAAST LT

. . . . . . . . 2

Connecting a PC to a FAAST Device for the First Time

2

Preparing to Configure or Monitor a FAAST LT Device

3

Monitoring a FAAST LT Device

3

Important Notes on Altering FAAST LT Settings

3

Configuring a FAAST LT Device

3

Sending a Configuration to a FAAST LT Device

4

Time and Date: Setting the Real Time Clock

4

Setting the Alarm Level (Stand Alone Versions Only)

4

FAAST LT Alarm Mode (Loop Based Versions Only)

4

Setting the FAAST LT Device Fan Speed

4

FAAST LT

FIRE ALARM ASPIRATION SENSING TECHNOLOGY

®

ADVANCED SET-UP AND CONTROL GUIDE

INTRODUCTION

The FAAST LT aspirating smoke detector is an advanced smoke

sensing system for use in early warning and very early warning

applications . The system continuously draws air from the controlled

environment through a series of sampling holes to monitor the

environment for smoke particulate . A range of sensing, operating

and output facilities can be configured in the FAAST LT unit by the

end user . This is accomplished by programming and downloading

control parameters from a PC running the proprietary software

application,

PipeIQ™

(Version 2.3 and above). This manual

describes how to monitor and configure the various operating

parameters available in a FAAST LT unit via the user interface

provided by PipeIQ™ .

Further PipeIQ™ Capabilities . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Creating a Project 5

Designing a Pipe Layout 5

Creating Reports 5

PipeIQ™ Help 5

Appendices

A: FAAST LT Config. Parameters and Default Set-Up Values

. 6

Configuration Parameters

6

Default Set-Up Values - Stand Alone Versions

10

Default Set-Up Values - Loop Based Versions

12

B: FAAST LT Fault Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14

C: Example Pipe Configurations

. . . . . . . . . . . . . . . . . . . . . . . .16

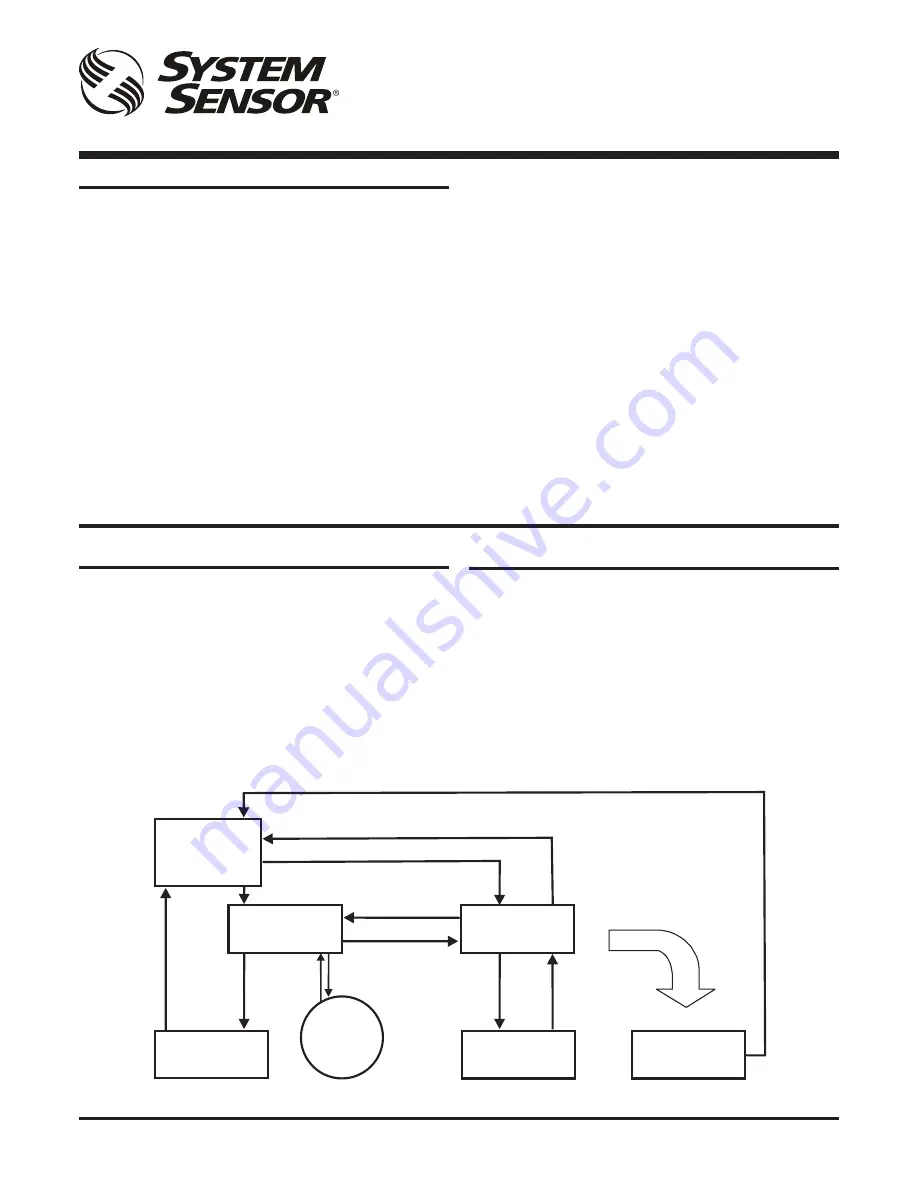

THE FAAST LT FUNCTIONAL STATE DIAGRAM.

In operation, the device can be in one of 6 possible states:

Initialization

Normal

Maintenance

Remote Maintenance

Service Mode

Power Out Of Range state

The routes in and out of these states are shown in the diagram

below .

MAINTENANCE

REMOTE

MAINTENANCE

SERVICE

MODE

POWER OUT OF

RANGE STATE

Power < 18V

Power > 32V

(Power-ON)

INITIALIZATION

NORMAL

DISPLAY

FAN

SPEED

USB

Disconnected

+ Cover Close

Cover Open +

USB

Connected

RESET +

DISABLE

RESET +

Password Enter

Cover

Open

Cover

Close

RESET + Password Enter (During Auto Speed Procedure)

Maintenance Timeout or after TEST + RESET + DISABLE (When Device Configuration has been Changed)

Maintenance Timeout or after

TEST + RESET + DISABLE

(No Need for Device to Initialize)

Power in Correct Range

Keep this document for future reference