52

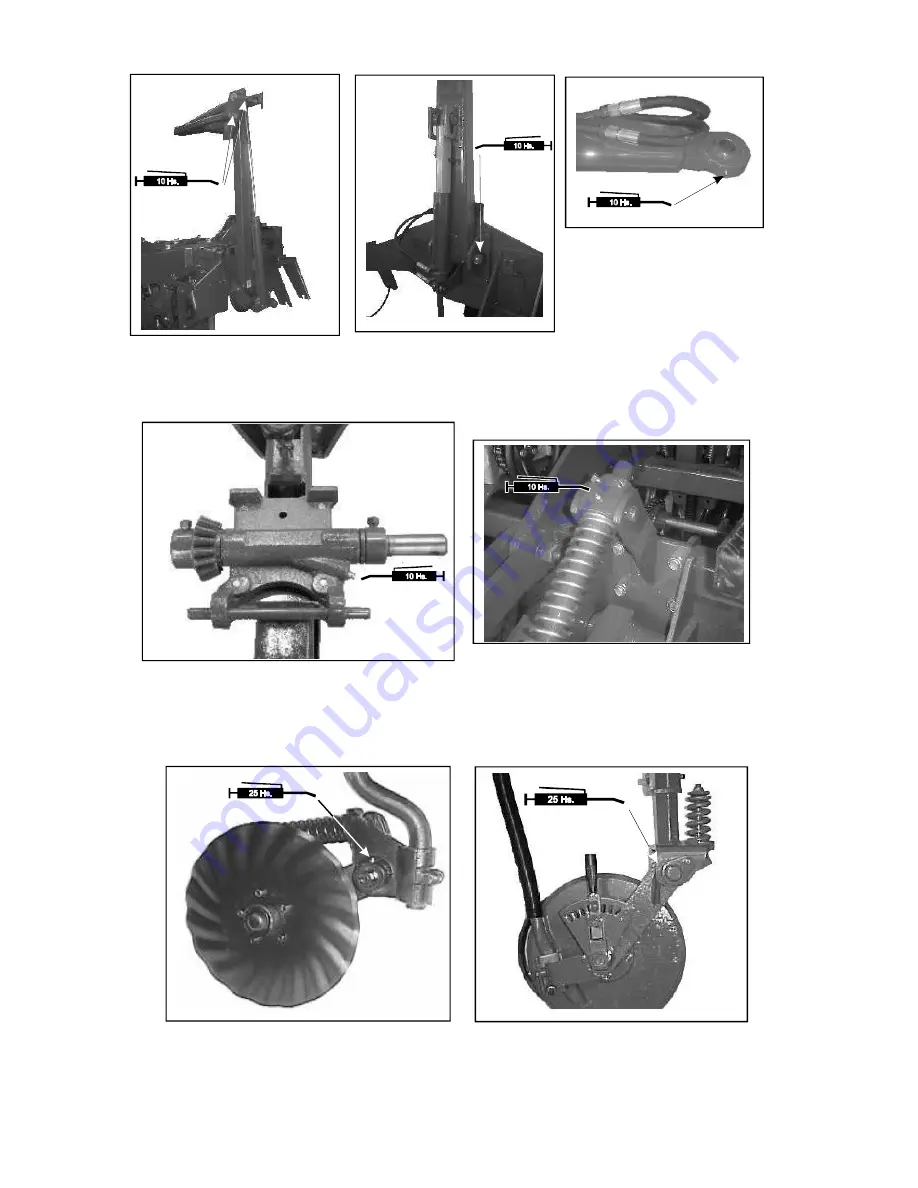

Figure 8: Coulter blades

bushings

Figure 9: Fertilizer discs

bushings

Lubricate every 25 hours. (Approximately every three days).

10 Hs.

10 Hs.

10 Hs.

10 Hs.

10 Hs.

Figure 4a and 4b: Bushing of the markers and

cylinders, 7 and 10 rows

Figure 5: Hitch bar

Figure 7: Contact drive wheel

articulation

Figure 6: Hopper support.

25 Hs.

25 Hs.

Summary of Contents for W630

Page 1: ...OPERATOR S MANUAL W 630...

Page 2: ...2...

Page 4: ...4...

Page 6: ...6...

Page 8: ...8...

Page 60: ...60 This page intentionally let blank...

Page 64: ...64 This page intentionally let blank...

Page 66: ...66...