79

11

Maintenance and Testing

When placing the system in service for the first time, when it has been out of service for

some time, after conversions and repair work, make certain the scanner and any other

safety parts are checked specifically for the application and operation by the responsible

trained specialist. This must be done taking into consideration applicable local

requirements, especially for guidelines on machines and using work material and work

safety guidelines. If the correct functionality is not clearly confirmed or if safety-related

parameters have been changed, turn OFF the machine or vehicle immediately.

Provisional measures are not permitted.

Please comply with the safety notes in Chapter 3!

11.1

Test before first startup by person qualified and authorized to

perform the task

11.2

Extended shutdown of the SD3-A1

If a system is taken out of operation and the

SD3-A1

is placed in storage for later use

with other machines / vehicles, the factory settings should be restored. Please see the

chapter entitled “Set default configuration values” in the instruction manual (software

operation) for the

SD3SOFT

.

x

Check in accordance with the guidelines cited above, using the checklists provided

following if necessary to verify that the protective equipment has been properly

attached is connected to the control system electrically and that its effect works in

all operating modes of the machine or vehicle.

x

The result of the test must be documented, along with the scanner setting, in an

understandable form. Printouts of scanner parameters and all defined detection

zone contours must be included with the materials. Keep these where they are

inaccessible for unauthorized personnel.

x

During initial startup, you should anticipate unexpected behavior in the machine or

vehicle. Because of this, people must be kept out of the danger area.

x

Operating personnel must be instructed by trained specialists before starting work.

Instruction is part of the area of responsibility of the machine operator.

x

Ensure that a daily test is performed. Please take note in this regard of the “Daily

test with the test piece performed by responsible operating personnel”.

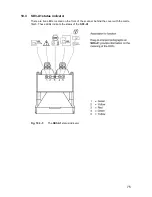

Summary of Contents for SD3-A1

Page 1: ......

Page 12: ...12...

Page 40: ...40 Fig 5 4 5 Considering the maximum measurement distance when safeguarding an area...

Page 60: ...60 Fig 6 2 1 Example of a zone pair changeover for an AGV on a curved route...

Page 61: ...61 Fig 6 2 2 Example of zone pair changeover with combined with reducing speed of the AGV...

Page 101: ...101 13 13 Dimensional drawings of the SD3 A1...

Page 102: ...102 13 14 Dimensional drawings of the mounting system...

Page 106: ......