13

7) Installation of the thread stand

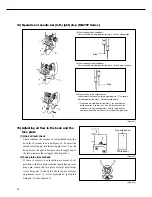

As can be seen in Figure 10, fix the thread stand

①

to the

table using the washer and nut on the right.

[Figure 10]

①

(3) Lastly, fasten the belt cover

“

B

”

to the table, as can be

seen in Figure 9.

[Figure 9]

8) Assembly of the location detector and its

control method

(1) Installation of the location detector

A. Installing on the servo motor (in-built location detector)

A location detector sensor is attached to the back side of

the arm. The appropriate clearance between the location

detector and the pulley is 4.7mm. (See Figure 11.)

B. Installing on the 470 motor (external location detector)

After assembling the parts in the numbered order as in Figure 12, adjust the synchronization shaft horizontally such that

the photo film is placed at the center of the photo interrupter as in Figure 13. Then fasten it tightly with two fixing screws

using a hexagonal wrench.

[Caution]

As can be seen on figure 12, make sure that the marks

“

DOWN

”

and

“

UP

”

face the front when looking from the pulley side.

Film adjustment is completed upon shipment.

Speed

Sensor Film

Fixed Washer

Fixed Bushing

Fixed

Screws

Pulley

L Wrench

PCB Holder

COVER

Photo

Interrupter

Photo Film

Synchronization Shaft

Synchronization

Shaft Fixing

Screws (2)

Location

detector

shaft

Fixed Washer

Clearance-

Adjusting Bushing

[Figure 11]

[Figure 12]

[Figure 13]

Summary of Contents for KM-757

Page 35: ...35 5 Table Drawing ...