23

C. Adjusting the distance between the needle and the hook edge

Raise the needle from its lowest point so that the hook center meets the needle center. Like in Figure 37, when the

lower shaft of the needle meets the balance point of the hook

’

s needle guide plate

①

(adjust the needle guide form),

adjust the distance between the hook edge and the inner side of the needle groove to 0.05~0.1mm. Loosen

①②③④

of Figure 38 and move the left and right

⑤

of the hook base for adjustment.

12) Clearance adjustment between the upper side of the hook stopper and the upper

side of the needle plate groove

Like in Figure 39, the normal distance between the hook stopper and the upper side of the needle plate groove is 1.3mm.

This distance is adjusted by the thickness of the space washer that lies under the hook. When the hook gear fixing screw

①

is removed for repair or replacement, make sure to put back the space washer that was used originally.

(The thickness of the washer may differ by machine.)

13) Clearance adjustment between the

hook and opener

Loosen the opener fastening screw

③

and adjust the opener

②

to the right and left so that the distance between the hook

①

and the opener

②

is 0.2mm when the opener

②

is pulled

to its max towards the arrowed direction. (See Figure 40.)

Hook edge

Needle

Adhering part

0.05~0.1mm

[Figure 37]

[Figure 38]

[Figure 39]

[Figure 40]

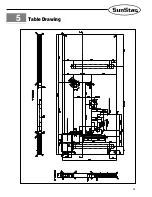

Summary of Contents for KM-757

Page 35: ...35 5 Table Drawing ...