Using the operator control panel (OCP)

The OCP has a power button, four LEDs, four control keys, and

a 2

‐

line by 16

‐

character LCD screen. With the OCP, you can

monitor, configure, and operate most Autoloader functions from the

Autoloader front panel.

See Page 12 for the OCP menu tree.

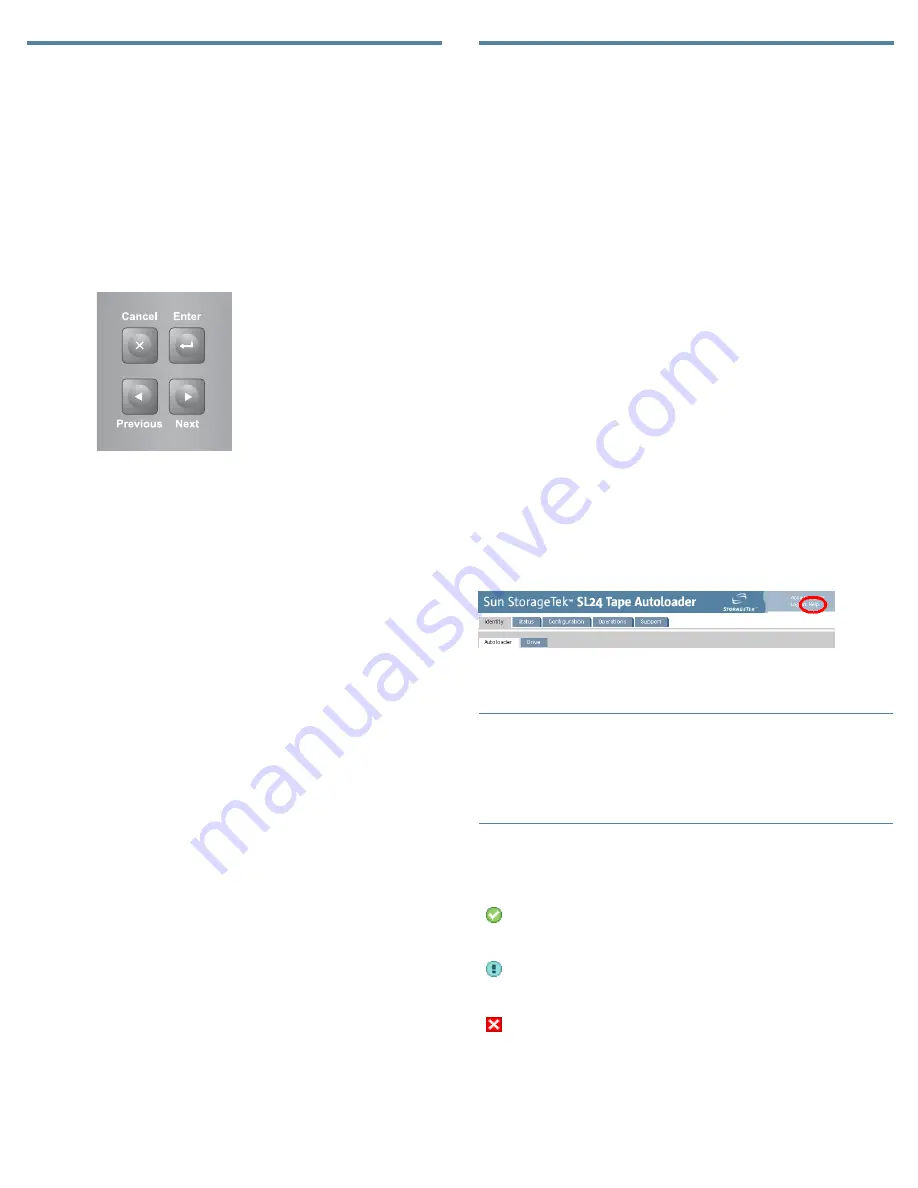

Control keys

The OCP displays a menu that lets you access information and

execute commands using the four control keys.

10763

Cancel

— Cancels the current menu option, returns to the previous

menu level, or returns to the Home screen.

Enter

— Executes the current menu or selects the current option

displayed on the LCD screen.

Previous

— Selects the previous item or value in the currently

displayed menu.

Next

— Selects the next item or value in the currently displayed menu.

LED indicators

The OCP has four LEDs that provide a variety of information.

Ready

— Green when power is on, blinking with tape drive or

Autoloader robotics activity.

Clean

— Amber when a cleaning cartridge should be used.

Attention

— Amber if the Autoloader has detected a condition that

requires attention.

Error

— Amber if an unrecoverable tape drive or Autoloader error

occurs. A corresponding error message displays on the LCD screen.

Using the remote management

interface (RMI)

With the RMI, you can monitor, configure, and operate most

Autoloader functions from a web browser.

Sun recommends that, when possible, the RMI be used as the

primary Autoloader interface because the web interface provides

access to additional features, includes online help, and is easier to

use. However, the RMI is not required to use the product, except

to configure SNMP, IPv6, and logical libraries. The only tasks you

cannot do from the RMI are:

•

Opening the mailslot.

•

Initiating the Wellness test.

•

Saving and restoring files and downloading firmware via a USB

flash drive.

To enable the Autoloader’s RMI, follow the instructions in this

installation process to:

•

Connect the Autoloader to your local area network with an

Ethernet cable (Step 9).

•

Configure the network (Step 10).

•

Set the Administrator password using the OCP (Step 12).

Logging in

Using the OCP, find the Autoloader’s IP address from the

Info

> Network

screen. Open any HTML web browser and enter

the Autoloader’s IP address. Select the account type. For the

administrator account, you must also enter the administrator

password. Click

Sign In

.

Once signed in, click

Help

in the upper right

‐

hand corner for more

information about the fields and information in the RMI.

NOTE:

The Autoloader is shipped without an administrator password.

You must set the administrator password with the OCP before you

can use the RMI’s administrator functions. Once the administrator

password is set, you can access the RMI by providing the

administrator password on the login screen.

Status icons

The green

Status OK

icon indicates that the

Autoloader is fully operational and that no user

interaction is required.

The blue exclamation point

Status Warning

icon

indicates that user attention is necessary, but that the

device can still perform most operations.

The red X

Status Error

icon indicates that user

intervention is required and that the device is not

capable of performing some operations.

Page 3