Chapter 3

CPU/ Boards and Components

3-3

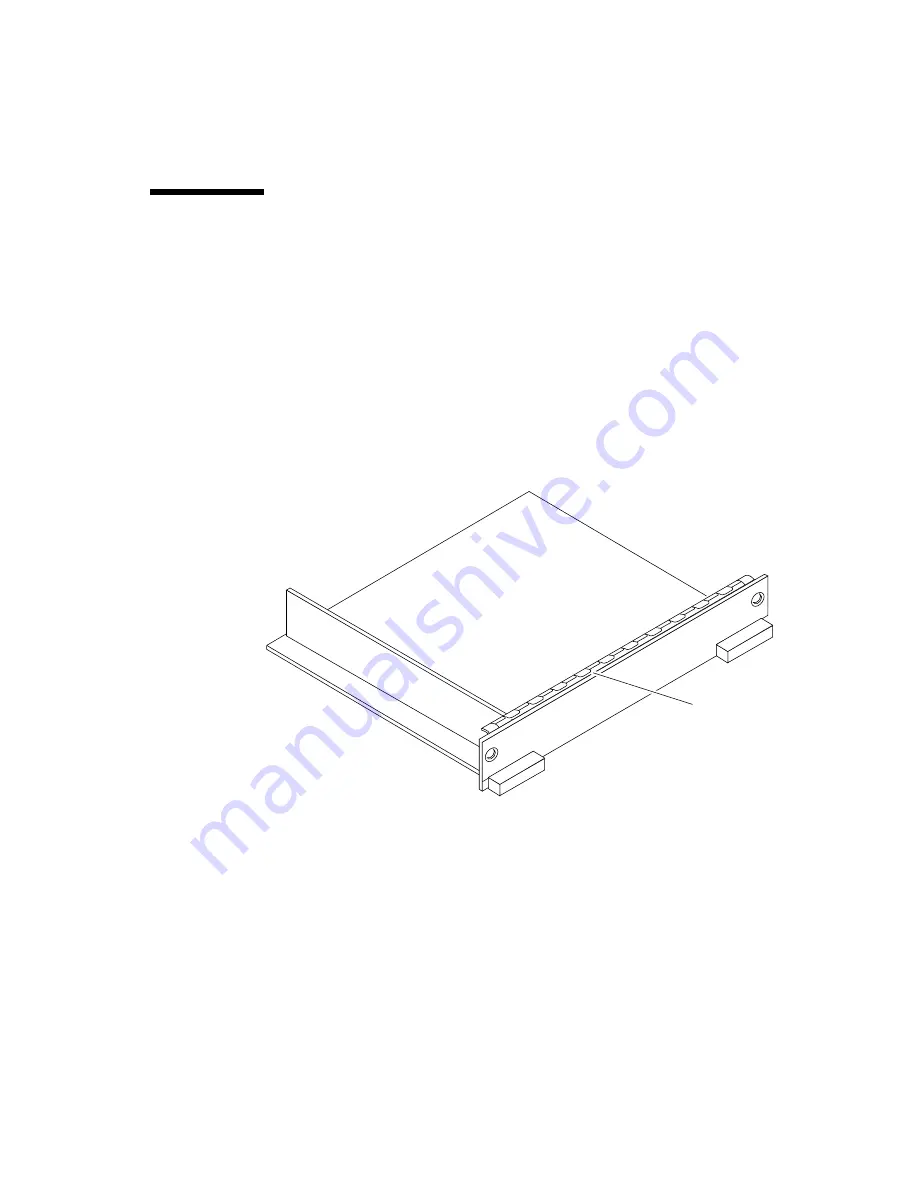

3.2

Filler Panels and Load Boards

All empty board slots in Enterprise systems must have either a filler panel or a load

board installed. (A load board is distinguished by the presence of centerplane

connectors. A filler panel has no centerplane connectors.)

■

Empty slots in Enterprise 5500 and 4500 systems must have a filler panel installed

(

).

■

Empty slots in Enterprise 6500 systems must have a load board installed

(

).

Load boards and filler panels are inserted into a board slot with the springfingers

facing down if inserted in the front of the system; the springfingers face up if

inserted in the rear of the system.

FIGURE 3-1

Filler Panel (Enterprise 5500/4500 Only)

Springfingers

Summary of Contents for 5500

Page 12: ...xii Sun Enterprise 6500 5500 4500 Systems Reference Manual April 1998 ...

Page 20: ...xx Sun Enterprise 6500 5500 4500 Systems Reference Manual April 1998 ...

Page 89: ...Chapter 4 I O Boards and Components 4 31 FIGURE 4 27 PCI Card Removal Catch mechanism ...

Page 94: ...4 36 Sun Enterprise 6500 5500 4500 Systems Reference Manual April 1998 ...

Page 128: ...7 14 Sun Enterprise 6500 5500 4500 Systems Reference Manual April 1998 ...

Page 172: ...11 10 Sun Enterprise 6500 5500 4500 Systems Reference Manual April 1998 ...

Page 184: ...12 12 Sun Enterprise 6500 5500 4500 Systems Reference Manual April 1998 ...

Page 208: ...B 20 Sun Enterprise 6500 5500 4500 Systems Reference Manual April 1998 ...

Page 272: ...F 24 Sun Enterprise 6500 5500 4500 Systems Reference Manual April 1998 ...

Page 290: ...G 18 Sun Enterprise 6500 5500 4500 Systems Reference Manual April 1998 ...