6.1 GENERAL

As you proceed in reading this section, it will be easy to

see that the Maintenance Program for the air compressor

is quite simple. The use of the service indicators provided

for the fluid filter, air filter and fluid separator will alert you

when service maintenance is required. When the WS

Controller display indicates service, maintenance for that

specific item is required. See instructions for each item in

Fluid Filter Maintenance on page 40.

6.2 DAILY OPERATION

Prior to starting the compressor, it is necessary to check

the fluid level in the receiver tank. Should the level be low,

simply add the necessary amount. If the addition of fluid

becomes too frequent, a simple problem has developed

which is causing this excessive loss. See the

Troubleshooting Guideon page 43 under EXCESSIVE

COMPRESSOR FLUID CONSUMPTION for a probable

cause and remedy.

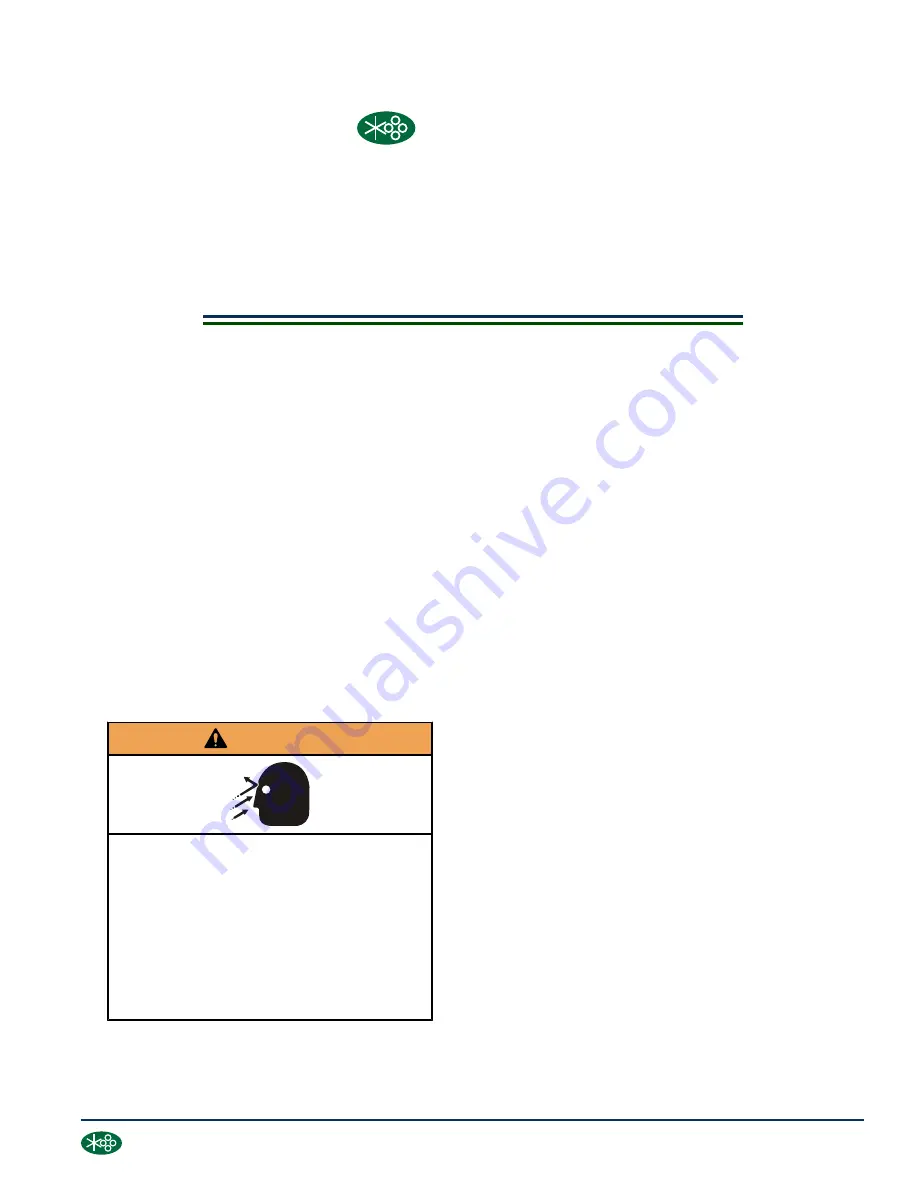

WARNING

HIGH-PRESSURE HAZARD!

• DO NOT remove caps, plugs, and/or

other components when

compressor is running or

pressurized. Stop compressor and

relieve all internal pressure before

doing so.

• Failure to comply could result in

death or serious injury.

After a routine start has been made, observe the controller

display and be sure it monitors the correct readings for

their particular phase of operation. After the compressor

has warmed up, it is recommended that a general check

on the overall compressor be made to assure that the

compressor is running properly.

6.3 MAINTENANCE EVERY 2000

HOURS

After 2000 hours of operation, it will be necessary to

perform the following:

1. Replace the fluid filter element.

6.4 FLUID MAINTENANCE

Drain the receiver tank and change the compressor fluid

using instructions shown in Lubrication Guide,

Lubrication Change Recommendations and Maintenance

®

SULLAIR

®

Section 6

MAINTENANCE

®

SULLAIR

®

1100e, 1500e, 1800e Operator’s Manual and Parts List

39

Summary of Contents for 1107e

Page 101: ...THIS PAGE INTENTIONALLY LEFT BLANK...