3.2 LUBRICATION GUIDE

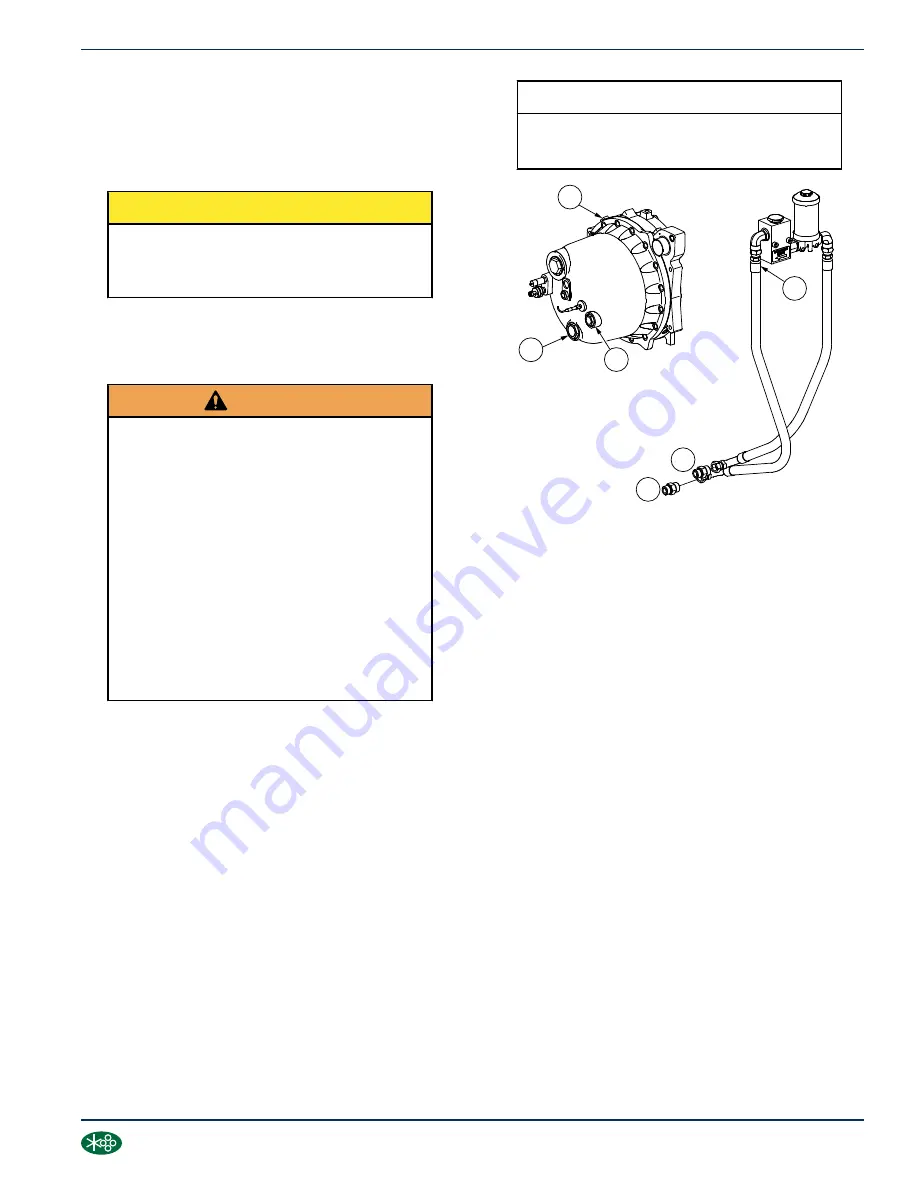

Refer to Figure 3-1 for location of fluid fill port. For best

value and longest uninterrupted service, the 1100e

through 1800e Series compressors are factory filled and

tested with Sullube lubricant.

CAUTION

Mixing of other lubricants within the

compressor unit will void all

warranties.

Refer to

Lubrication Change Recommendations and Maintenance

- Fluid Filter and Separator on page 18 if fluid change is

required.

WARNING

"The Plastic Pipe Institute

recommends against the use of

thermoplastic pipe to transport

compressed air or other compressed

gases in exposed above ground

locations, e.g. in exposed plant

piping." (I)

Sullube should not be used with PVC

piping systems. It may affect the bond

at cemented joints. Certain other

plastic materials may also be affected.

(I) Plastic Pipe Institute,

Recommendation B, Adopted

January 19, 1972.

Maintenance of all other components is still recommended

as indicated in the Operator’s Manual.

DO NOT MIX DIFFERENT TYPES OF FLUIDS.

Contamination of non-detergent mineral fluids with traces

of detergent motor fluids may lead to operational problems

such as foaming, filter plugging, orifice or line plugging.

NOTE

Flush system when switching

lubricant brands.

SU_0000087

6

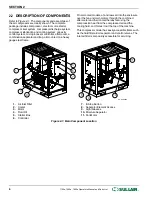

1

2

3

4

5

1. Fluid Fill Port

2. Sight Glass - Low Level (Machine Off)

3. Sight Glass - Maximum Level (Machine Off)

4. Hose - Detach for Fluid Draining

5. From Drive Housing Oil Outlet

6. To Drive Housing Oil In

Figure 3-1: Fluid Fill Location

3.3 APPLICATION GUIDE

Sullair encourages the user to participate in a fluid analysis

program with the fluid suppliers. This could result in a fluid

change interval differing from that stated in the manual.

Contact your Sullair dealer for details.

SPECIFICATIONS

®

SULLAIR

®

1100e, 1500e, 1800e Operator’s Manual and Parts List

17

Summary of Contents for 1107e

Page 101: ...THIS PAGE INTENTIONALLY LEFT BLANK...