2.4 COMPRESSOR COOLING AND

LUBRICATION SYSTEM,

FUNCTIONAL DESCRIPTION

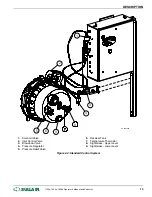

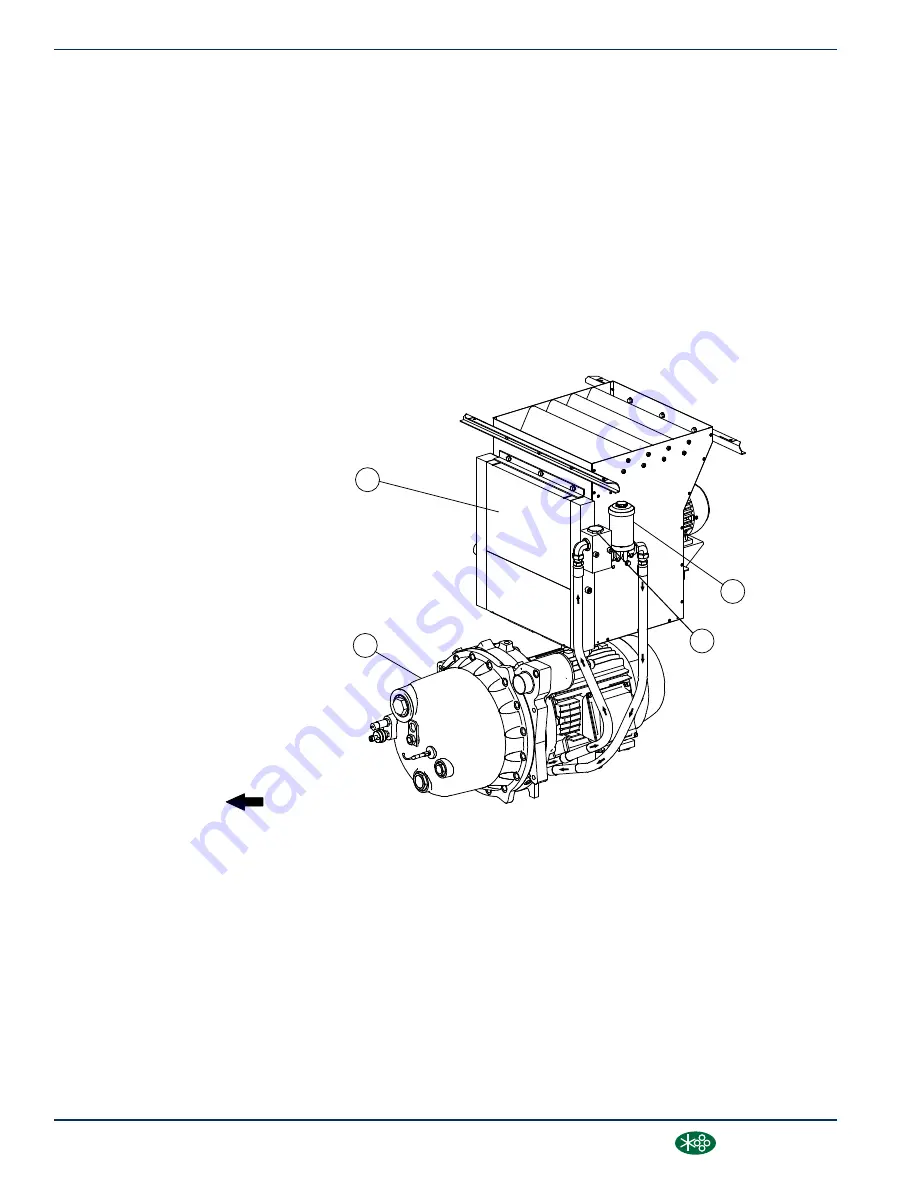

Refer to Figure 2-2. The Cooling and Lubrication System

consists of a fan, fan motor, radiator-type aftercooler/fluid

cooler, full flow fluid filter, thermal valve, and

interconnecting hoses. The pressure in the receiver tank

causes fluid flow by forcing the fluid from the high pressure

area of the receiver tank to an area of lower pressure in the

compressor unit.

Fluid flows from the bottom of the receiver tank to the

thermal valve. The thermal valve is fully open when the

fluid temperature is below 185˚F (85˚C). The fluid passes

through the thermal valve, the main filter and directly to the

compressor unit where it lubricates, cools and seals the

rotors and the compression chamber.

As the discharge temperature rises above 185˚F (85˚C),

due to the heat of compression, the thermal valve begins

to close and a portion of the fluid then flows through the

cooler. From the cooler the fluid flows to the fluid filter and

then on to the compressor unit.

A portion of the fluid flowing to the compressor is routed to

the anti-friction bearings which support the rotors inside

the compressor unit.

The fluid filter has a replacement element and an integral

pressure bypass valve. A message on the controller

indicates when the fluid filter needs to be changed.

FLUID

SU_0000083

1

2

3

4

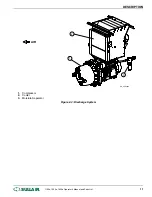

1. Compressor

2. Cooler

3. Fluid Filter

4. Thermal Valve

Figure 2-2: Cooling and Lubrication System

SECTION 2

8

1100e, 1500e, 1800e Operator’s Manual and Parts List

®

SULLAIR

®

Summary of Contents for 1107e

Page 101: ...THIS PAGE INTENTIONALLY LEFT BLANK...