II/12

BAM/CPM/SUM/UNM/ZPM

GB

2.6.1 Before each maintenance

task

1. Swtich on the compressor at the ON/OFF

switch (item 10). Disconnect the power

supply.

2. Depressurise the compressor: using the

blow gun, blow out all pressure from the

vessel.

2.6.2 Cleaning the compressor

• Clean the cooling fins on the cylinder, cyl-

inder head and aftercooler using com-

pressed air.

• Clean the fan impeller cover on the motor.

2.6.3 Clean the filter pressure re-

ducer insert

1. Depressurise the vessel of the filter pres-

sure reducer.

2. Hold a suitable vessel under the conden-

sate drain. Drain condensate.

3. Remove the vessel of the filter pressure

reducer. Unscrew the mounting screw of

the filter insert by screwing anticlockwise

(Figure 4a).

4. Remove the filter insert, clean in soapy

water (max. 50 °C).

5. Installation is in reverse order.

2.6.4 Draining condensate from

filter pressure reducer

Draining semi-automatically:

Rotate the

condensate drain valve 1/4 turn anticlock-

wise. Under 1 bar: condensate drains. (Fig-

ure 4a)

Draining manually:

Rotate the condensate

drain valve clockwise and push it up. Con-

densate drains.

2.6.5 Draining condensate from

pressure vessel

L

Condensate is a water pollutant. Dispose

of it according to applicable regulations!

1. Place a suitable vessel under the conden-

sate drain.

2. To drain condensate, the pressure may

be no more than 2 bar.

3. Open the condensate drain valve

(item 09): rotate 1 1/2 turns anticlock-

wise.

4. Rotate the condensate drain valve clock-

wise to block it.

2.6.6 Checking the oil level

For compressors with an oil dipstick, pull the

dipstick out.

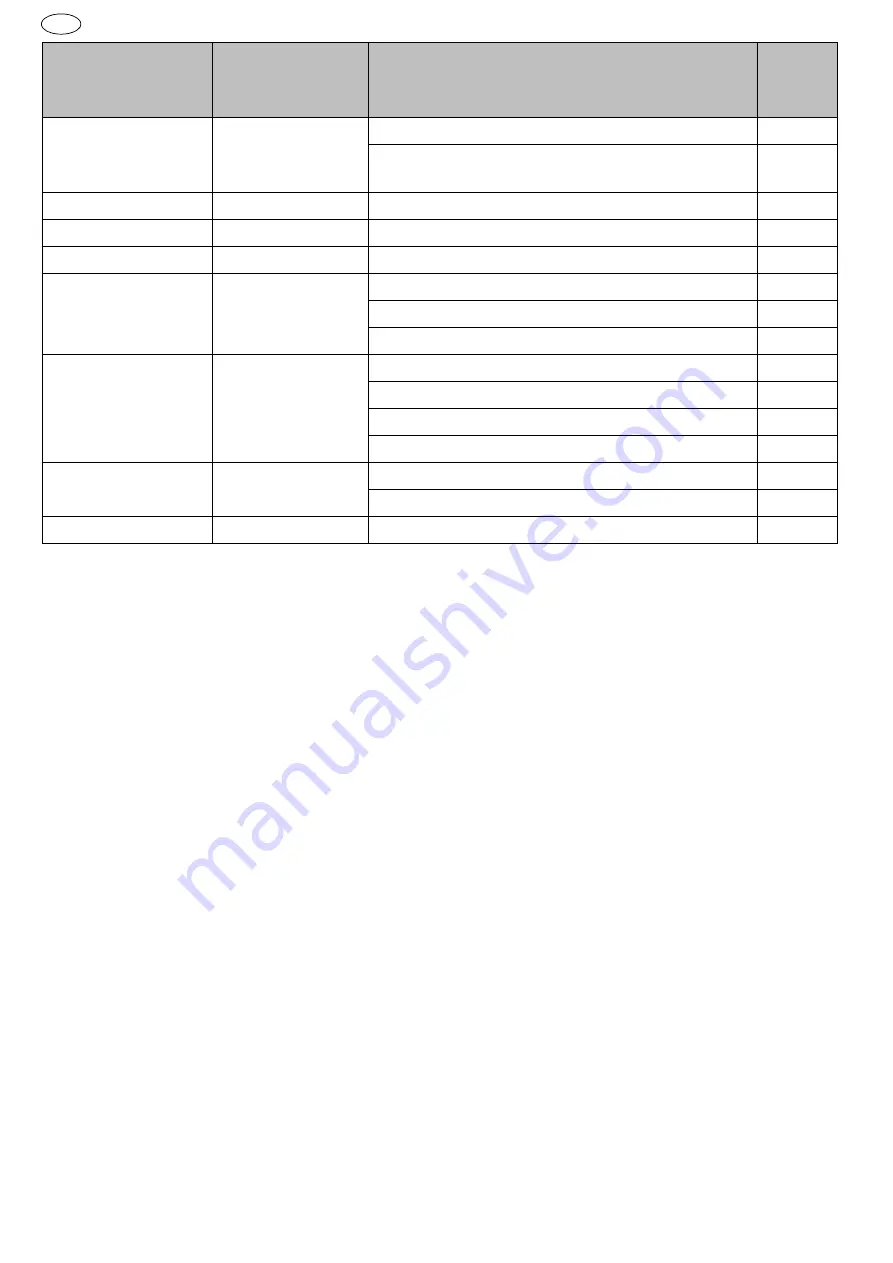

After each use

Drain condensate from pressure vessel

2.6.5

Drain condensate from filter pressure

reducer

2.6.4

Daily

Commissioning

Check the oil level, add oil if necessary.

2.6.6

Once after 10 h

Check screw connections

2.6.8

Weekly

Check intake filter

2.6.9

50 h

After 6 months

Check V-belt tension (where applicable)

2.6.10

Clean intake filter

2.6.9

Change oil (1st oil change)

2.6.7

500 h

After 1 year

Change oil (mineral oil)

2.6.7

Change intake filter

2.6.9

Change check valve and insert

2.6.11

Check screw connections

2.6.8

1,000 h

After 2 years

Change oil (synthetic oil)

2.6.7

Change V-belts (where applicable)

2.6.10

2,500 h

After 5 years

Change safety valve

2.6.12

Interval

No later than

Tasks

See

chap-

ter

Summary of Contents for STROCOMP 400

Page 2: ......

Page 3: ......

Page 4: ......

Page 73: ...BAM CPM SUM UNM ZPM II 53 RUS 1 2 3 Schneider Druckluft GmbH 1 X X X X X X X X...

Page 78: ...II 58 BAM CPM SUM UNM ZPM RUS 8 2 7 2 2 8 X B X C X X X A X D X 2 4 4...

Page 79: ...BAM CPM SUM UNM ZPM II 59 RUS E X X X X 2 6 5 X X F X G X 2 6 11 X H X 2 6 5 X E I X X J X X X...