BAM/CPM/SUM/UNM/ZPM

II/15

GB

2.9 Spare parts service

Visit our website www.schneider-airsys-

tems.com/td/ for the latest version of all ex-

ploded drawings and spare parts lists for our

products. If you have any special questions,

please consult the Schneider Airsystems Ser-

vice centre in your country (addresses in the

service appendix) or your local dealer.

E

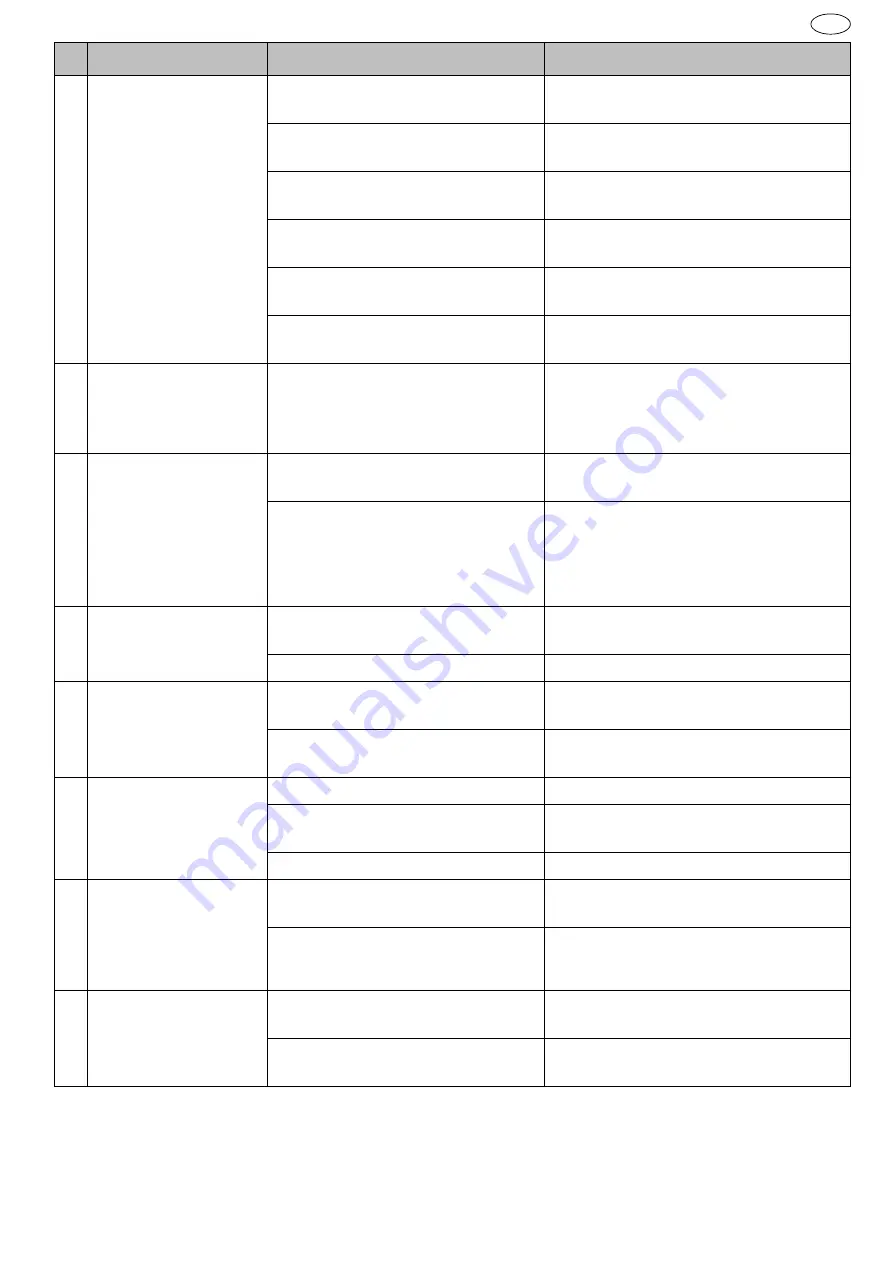

Compressor runs

continuously.

Intake filter badly contami-

nated.

X

Clean or replace intake filter.

Air consumption of compressed

air tools is too high.

X

Check the air consumption of the

tools. Contact the service partner

Leakage at compressor.

X

Locate leak, contact service part-

ner.

Excessive condensate in the

vessel.

X

Drain the condensate (see

Chap. 2.6.5).

Compressed air line leaky:

X

Check compressed air line, plug

leak.

Condensate drain valve is open

or missing.

X

Close or replace.

F

During operation,

compressed air

escapes via the

load-relieving valve.

Load-relieving valve leaky.

X

Clean or replace load-relieving

valve.

G After the switch-off

pressure is reached,

compressed air

escapes via the

load-relieving valve

until switch-on

pressure is reached

Check valve insert leaky or

defective.

X

Clean or replace the check valve

insert (see Chap. 2.6.11).

Check valve is damaged.

X

Replace check valve.

H Compressor

switches on fre-

quently.

Excessive condensate in the

pressure vessel.

X

Drain the condensate (see

Chap. 2.6.5).

Compressor overloaded.

X

See item E

I

Safety valve blows

out.

Vessel pressure is higher than

the set switch-off pressure.

X

Have the pressure switch reset/

replaced by a qualified person.

Safety valve is defective.

X

Replace safety valve or contact

service partner.

J

Compressor over-

heats.

Air supply not sufficient.

X

Ensure sufficient ventilation.

Cooling fins on cylinder (cylin-

der head) contaminated.

X

Clean cooling fins on cylinder

(cylinder head).

Duty cycle too long.

X

Switch off compressor.

K Oil-lubricated com-

pressor: the oil

level rises without

oil having been

added.

Condensate collects in the oil.

X

Compressor is too large, contact

service partner.

High humidity.

X

Change oil.

L

V-belt driven com-

pressor: unusual

running noises.

V-belt or belt disc is scraping

against belt guard grating.

X

Look for point of contact, remedy

error

V-belt sags.

X

Tighten the V-belt (see

Chap. 2.6.10)

Problem

Cause

Remedy

Summary of Contents for STROCOMP 400

Page 2: ......

Page 3: ......

Page 4: ......

Page 73: ...BAM CPM SUM UNM ZPM II 53 RUS 1 2 3 Schneider Druckluft GmbH 1 X X X X X X X X...

Page 78: ...II 58 BAM CPM SUM UNM ZPM RUS 8 2 7 2 2 8 X B X C X X X A X D X 2 4 4...

Page 79: ...BAM CPM SUM UNM ZPM II 59 RUS E X X X X 2 6 5 X X F X G X 2 6 11 X H X 2 6 5 X E I X X J X X X...