II/14

BAM/CPM/SUM/UNM/ZPM

GB

4. Allow the compressor to warm up, switch

it off.

5. Refit intake filter, seal watertight with

Scotch tape.

6. Switch off the compressor. Disconnect

the power supply.

7. Drain condensate.

8. Depressurise the compressor.

Store the compressor dry and do not subject

it to large temperature fluctuations.

2.7.2 Disposal

Dispose of the unit and packaging materials

according to applicable regulations.

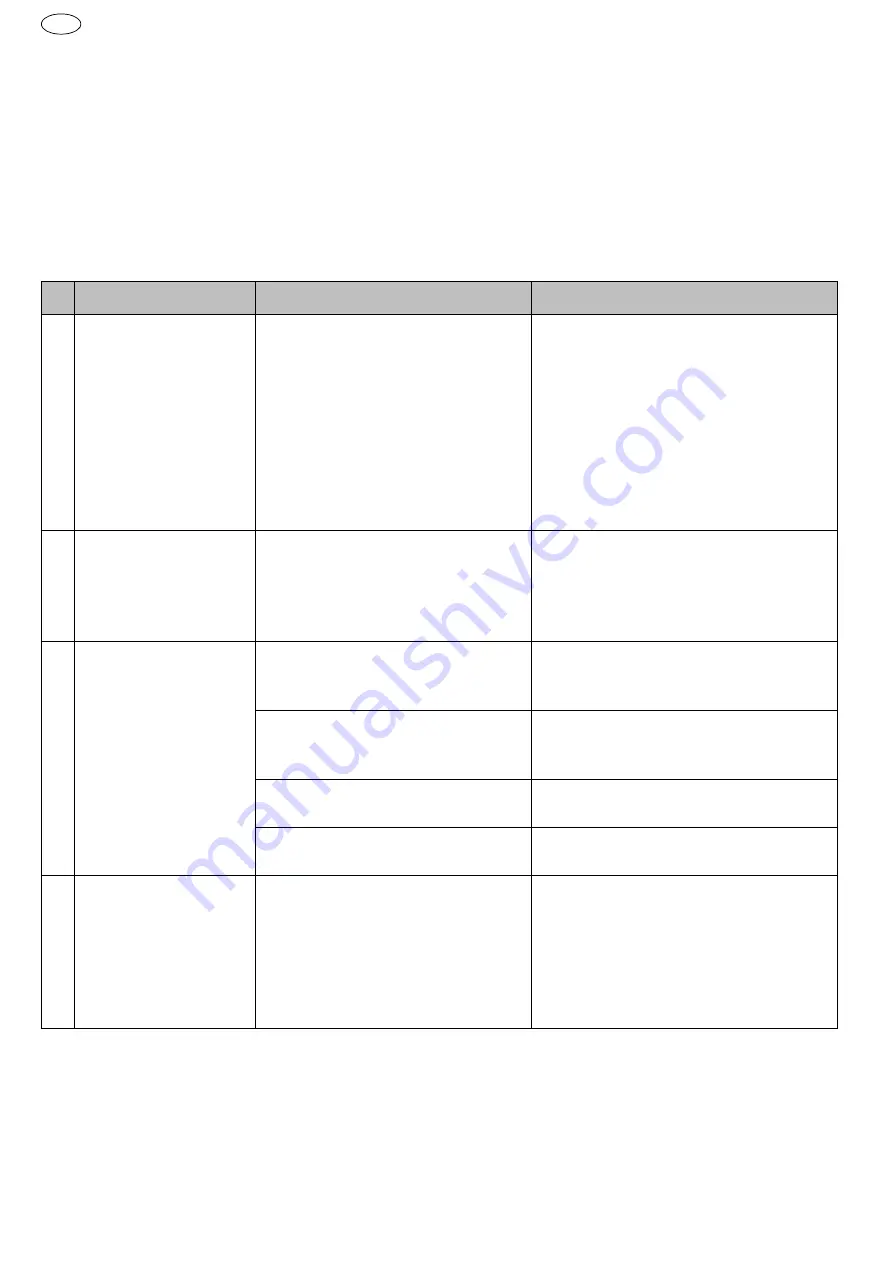

2.8 Troubleshooting

Observe the safety instructions!

Problem

Cause

Remedy

A Protective motor

switch interrupts

power supply.

In case of malfunctions (e.g.

overheating; low voltage;

extension cable too long or

with incorrect cross-section),

the protective motor switch is

tripped.

X

Switch off the compressor. Wait

a short while. For compressors

with an external protective motor

switch: actuate the switch.

Switch on the compressor.

If the protective motor switch is

triggered again: switch off the

compressor. Disconnect the pow-

er supply. Contact the service

partner.

B Pressure relief does

not function

The pressure relief is shut

down by an interruption of the

power supply or voltage drop in

the mains when the compres-

sor is switched on.

X

Switch off the compressor. It de-

pressurises. Switch on the com-

pressor.

C Compressor does

not start when

switched on.

Vessel pressure is higher than

switch-on pressure.

X

Relieve pressure in the vessel

until the pressure switch is acti-

vated automatically.

Power supply faulty.

X

Have the power supply checked

by a qualified person (service

partner).

Protective motor switch inter-

rupts power supply.

X

See item A.

Pressure switch defective

X

Have the pressure switch

changed by a qualified person.

D The compressor

starts up briefly

when the switch-on

pressure is reached

or hums, then

switches off auto-

matically.

Mains connection cable longer

than permitted or the cross

section is too small.

X

Check connection cable length

and cable cross-section (see

Chap. 2.4.4)

Summary of Contents for STROCOMP 400

Page 2: ......

Page 3: ......

Page 4: ......

Page 73: ...BAM CPM SUM UNM ZPM II 53 RUS 1 2 3 Schneider Druckluft GmbH 1 X X X X X X X X...

Page 78: ...II 58 BAM CPM SUM UNM ZPM RUS 8 2 7 2 2 8 X B X C X X X A X D X 2 4 4...

Page 79: ...BAM CPM SUM UNM ZPM II 59 RUS E X X X X 2 6 5 X X F X G X 2 6 11 X H X 2 6 5 X E I X X J X X X...