4T/2T Trigger Control Switch (Ref. 14)

– This switch controls the trigger mode

for the MIG torch trigger. 2T mode the trigger is pulled and held on to activate

the welding circuit, when the trigger is released, the welding circuit stops.

4T is known as ’latching’ mode. The trigger is pulled once and released to

activate the welding circuit, pulled and released again to stops the welding

circuit. This function is useful to longer welds as the trigger is not required to

be held continuously.

LIFT TIG Mode Switch (Ref. 13)

– Lift TIG is an arc ignition system for TIG

welding that removes the need to ‘scratch’ start or strike the tungsten on the

work piece to start the arc, which can have a negative effect on the weld

quality from tungsten contamination. Lift arc starting works by gently touching

the tungsten on the work piece and then lifting it off. The control circuit will

sense when the tungsten is removed from the work piece and send a pulse of

electricity through the torch that will cause the TIG arc to initiate.

Wire Feed (Inching) Switch (Ref. 15)

– Depressing this button will cause the

wire feeder to run at maximum speed without the welding power circuit to be

activated. This is a safe and helpful function for loading wire through the torch

cable prior to welding or when replacing the wire spool.

36V AC Auxiliary Power Supply (Ref. 20)

– May be used to power accessories

that require 36V AC power supply such as 36V heated CO2 regulator (optional

accessory).

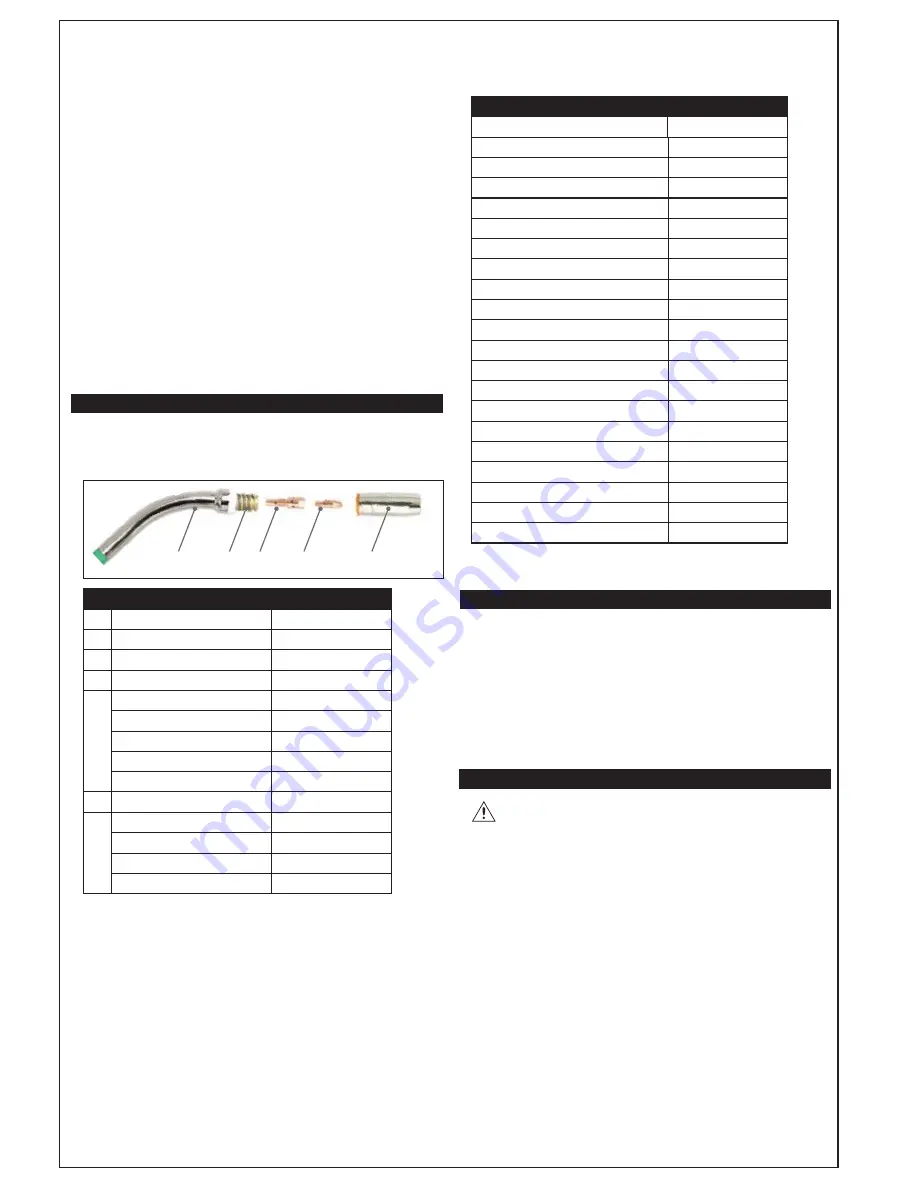

CONSUMABLES & ACCESSORIES

It is very important to recognise that welding torch consumables wear as part

of normal operation and should be replaced in a timely manner. Operating a

torch with worn consumables will cause poor welding results and possible

damage to the torch and machine itself.

1

2

3

4

5

MT250 3m Torch Consumables

No.

Description

Code

1

Swan Neck

MSN2554

2

Shroud Spring

MSS2557

3

Tip Adaptor

MTA2581

4

Contact Tip 0.6mm

MMT2406

Contact Tip 0.8mm

MMT2408

Contact Tip 0.9mm

MMT2409

Contact Tip 1.0mm/0.8mm Alum

007

Contact Tip 1.2mm/1.0mm Alum

MMT2412

5

Conical Nozzle

MCN2570

Wire Liner 0.6-0.9mm Steel 3m

MSL1539

Wire Liner 1.0-1.2mm Steel 3m

MSL2432

Wire Liner 0.6-0.8mm Teflon 3m

MTL1538T

Wire Liner 1.0-1.2mm Teflon 3m

MTL2432T

7KHVHZHDULQJWRUFKFRQVXPDEOHVDQGWKHOLVWRIDFFHVVRULHVIROORZLQJDUH

DOODYDLODEOHIURP\RXUQHDUHVW675$7$VWRUH

Accessories / Consumables

Description

Code

Welding Helmet Professional

':

Professional Welding Gloves

$:*

Argon Regulator

*5$5

MIG Welding Tip Dip Gel 120g

7'

Welding Magnet - 5"

:0*

MIG Wire 0.6mm Mild Steel, 5kg

MW5KG06

MIG Wire 0.8mm Mild Steel, 5kg

0:.*

MIG Wire 0.8mm Flux Cored, 5kg

0:.*)&

MIG Wire 0.8mm Mild Steel, 15kg

0:.*

MIG Wire 0.9mm Mild Steel, 15kg

MW15KG09

MIG Wire 1.0mm Mild Steel, 15kg

MW15KG10

Spool Gun 6m

SP100N

WP17 Valve TIG Torch 4m

TWP17-12-2D

WP26 Valve TIG Torch 4m

TWP26-12-2

1.0/1.2 mm 'U' Groove Drive Roller

WT 48DRU

0.8/1.0 mm 'V" Groove Drive Roller

WT 49DRV

0.8/0.9mm Knurled Groove Drive Roller

WT78DRK

0.6/0.8mm 'V' Groove Drive Roller

WT80DRV

MB15 MIG torch 3m (Euro)

MT150-3E

MB25 MIG torch 3m (Euro)

MT250-3E

)RUDOORWKHUVSDUHSDUWVDQGDFFHVVRULHVSOHDVHFRQWDFW\RXU

ORFDO675$7$VWRUH

WELDER INSTALLATION

(OHFWULFDO&RQQHFWLRQ

7KH

;0352

LVGHVLJQHGWRUXQRQDVWDQGDUG$9$&SRZHUVXSSO\

,IDQH[WHQVLRQFRUGPXVWEHXVHGLWVKRXOGEHQRORQJHUWKDQPDQGEHD

KHDY\GXW\LQGXVWULDO$YHUVLRQZLWKDPLQLPXPFDEOHFRUHRIPP

2SHUDWLQJ(QYLURQPHQW

$GHTXDWHYHQWLODWLRQLVUHTXLUHGWRSURYLGHSURSHUFRROLQJIRUWKH

;0352

(QVXUHWKDWWKHPDFKLQHLVSODFHGRQDVWDEOHOHYHOVXUIDFHZKHUHFOHDQFRRODLU

ZLOOHDVLO\

n

RZDFURVVWKHXQLW7KH

;0352

KDVHOHFWULFDOFRPSRQHQWVDQG

FRQWUROFLUFXLWERDUGVZKLFKZLOOEHGDPDJHGE\H[FHVVLYHGXVWDQGGLUWDFOHDQ

RSHUDWLQJHQYLURQPHQWLVHVVHQWLDO

MIG WELDING SET UP & OPERATION

DANGER

Before adjusting the feed roller or wire spool, ensure that the

mains power is switched off.

1. Fitting Wire Spool

Open the wire spool cover. Unthread the wire spool retainer. Fit the wire spool

to spool holder shaft, ensuring that the wire exits towards the bottom.

Set the spool brake tension by adjusting the spool tension adjustment nut

before replacing the wire spool retainer. The spool brake tension should be

set so that the spool can rotate freely, but does not continue to rotate once

the wire feed stops. This may need to be adjusted as the wire is used and the spool

weight decreases.

CAUTION:

Excessive spool brake tension will cause wire feeding issues and affect

welding performance as well as contribute to premature failure/ wear of wire feed

components.

Feed the wire from the spool through the Wire Drive Inlet Guide (24) into the

wire feeder.

Release the Wire Feed Tension Arms (25) by pivoting the Wire Feed Tension

Adjustment Lever (26) from the vertical to the horizontal position.

Check that the groove type of the Wire Drive Rollers (27) match the selected

MIG wire type and size. Each pair of drive rollers have two different sized grooves;

the size of the groove in use is stamped on the side of the drive roller.

ZZZVWUDWDFRQ]