50

6.2.2 FROZEN PRODUCT ON HOPPER WALLS

CAUSE

CORRECTION

Heavy freezer usage ..................................................... There is no correction required if the E.P.R. valve setting is

...................................................................................... correct. Some product freezing to the walls during heavy freezer

...................................................................................... operation is normal.

E.P.R. valve needs adjusting. ....................................... Make appropriate adjustment. Refer to Refrigeration Section 4,

...................................................................................... Subsection 4.10.

6.2.3 OVERNIGHT BARREL MELTDOWN DID NOT OCCUR

CAUSE

CORRECTION

Unit left in HOLD READY mode .................................... If time permits, turn power OFF, then ON to place freezer into

...................................................................................... standby mode. Barrel meltdown will immediately begin and should

...................................................................................... be complete in approximately 3 hours.

-OR-

...................................................................................... Clean and refill with fresh product.

Freezer nonusage timespan is too short for

complete meltdown ....................................................... Freezer nonusage period is approximately eight (8) hours to

...................................................................................... assure a complete barrel meltdown.

Control idle (standby) ‘STB’ temperature is too

low ................................................................................. Raise the idle temperature 3.2°F (refer to control setup procedure

...................................................................................... in subsection 3.2).

Liquid line solenoid valve failed to open ....................... *Replace liquid line solenoid valve coil or entire valve.

Cap tube is partially or completely blocked .................. *Check if E.P.R. valve setting can be achieved during freezing. If

...................................................................................... not, replace the cap tube.

6.2.4 OVERNIGHT BARREL TEMPERATURE IS TOO WARM

CAUSE

CORRECTION

Control idle (standby) ‘STB’ temperature is

too high ......................................................................... Lower the idle temperature 2° to 4°F (refer to contol setup

...................................................................................... procedure in subsection 3.2).

6.3

ELECTRO-MECHANICAL

6.3.1 FREEZER STARTS IMMEDIATELY AFTER POWER IS TURNED ON

CAUSE

CORRECTION

The barrel sensed temperature exceeds the idle

(standby) ‘STB’ temperature plus the ‘LKG STB’

value. ............................................................................ None required. This is proper freezer operation. Freezing will

...................................................................................... continue until the barrel sensed temperature equals the idle

...................................................................................... temperature less the ‘LKG STB’ value. The freezer is in standby

...................................................................................... mode at this time.

6.3.2 FREEZER WILL NOT START AFTER POWER IS TURNED ON

CAUSE

CORRECTION

Freezer is unplugged .................................................... Plug in freezer.

Blown fuse or tripped circuit breaker in building ........... Check for blown fuse or tripped circuit breaker in building and

...................................................................................... replace.

Side panel is removed .................................................. Install side panel or pull out side panel interlock switch plunger.

Door is removed ............................................................ Install door.

Door pin is missing or broken ....................................... Replace the door pin.

Door interlock switch requires adjustment .................... Adjust switch so door pin activates the switch.

Unit is in an ERROR condition ...................................... Refer to Troubleshooting Subsection 6.4.

OFF/ON switch has a loose wire or is defective ........... Check, repair or replace switch.

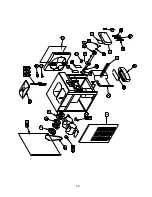

Summary of Contents for E131G

Page 1: ...Model E131G F131G SERVICE MANUAL Manual No 513537 3 Mar 2004...

Page 2: ......

Page 14: ...6...

Page 38: ...30 Figure 51 Power Board...

Page 39: ...31 Figure 52 Program Module...

Page 54: ...46...

Page 66: ...58...

Page 68: ...60...

Page 69: ...61 666786...

Page 70: ...62...

Page 71: ...63...

Page 72: ...64...

Page 73: ...65...

Page 74: ...66...

Page 75: ...67...

Page 76: ...68...

Page 77: ...69...

Page 78: ...70...

Page 80: ......