49

Control ‘LKG’ temperature is too high/low. .................. Control ‘LKG’ temperature should approximately equal or

...................................................................................... slightly exceed the desired product serving temperature;

...................................................................................... change accordingly (refer to control setup procedure in

...................................................................................... subsection 3.2).

Mix inlet regulator leaking air and/or mix. ..................... Check and/or replace missing, worn, or damaged o-rings

...................................................................................... and floating check balls. Lubricate o-rings accordingly.

NOTE

Avoid lubrication of check balls. Check balls must float freely.

Warm mix in hopper. ..................................................... Use prechilled mix in hopper.

Condenser and/or condenser filter is dirty. ................... Clean condenser and/or filter.

Freezer operating in HOLD READY mode with

low usage (product breakdown). ................................... If time permits, turn power OFF, then ON to place freezer

...................................................................................... into standby mode. Barrel meltdown will immediately begin

...................................................................................... and should be complete in approximately 3 hours.

-OR-

...................................................................................... Clean and refill with fresh product.

Product breakdown. ...................................................... Same as above.

Fan or fan motor is defective. ....................................... Check, repair or replace.

6.1.3 LOW OVERRUN

CAUSE

CORRECTION

Mix inlet regulator air tube is plugged. .......................... Unplug by using small sanitized brush.

Mix inlet regulator leaking air and/or mix. ..................... Check and/or replace missing, worn or damaged o-rings and

...................................................................................... floating check balls. Lubricate o-rings accordingly.

NOTE

Avoid lubrication of check balls. Check balls must float freely.

Legs are loose or freezer is not level. ........................... Check legs, level top of freezer.

Mix inlet regulator is being removed during

Freezing. ....................................................................... Do not remove mix inlet regulator during freezing.

Auger flights and/or springs are worn or missing. ........ Replace flights and/or springs.

Incorrect use of overrun scale. ..................................... Refer to Mix Characteristics section.

Product breakdown. ...................................................... Clean freezer, use new mix.

6.1.4 MIX SPRAY WHEN SPIGOT IS OPENED

CAUSE

CORRECTION

Slightly elevated pressure in the barrel after

meltdown is maintained by the mix inlet

regulator check balls. .................................................... Open spigot slowly to relieve the elevated pressure in the

barrel before dispensing product.

6.2

BARREL AND HOPPER MIX TEMPERATURE MAINTENANCE

6.2.1 HOPPER TEMPERATURE IS TOO WARM

CAUSE

CORRECTION

Warm mix in hopper. ..................................................... Use prechilled mix in hopper.

Not using insulated cover. ............................................ Use insulated cover.

E.P.R. valve needs adjusting. ....................................... Make appropriate adjustment. Refer to Refrigeration

...................................................................................... Section 4, Subsection 4.10

Ambient temperature is very warm. .............................. Move or direct hot air away from freezer.

Control ‘STB’ temperature is too high. .......................... Lower the ‘STB’ temperature 2° to 4°F accordingly. (Refer to

...................................................................................... setup procedure.)

Cap tube is partially or completely blocked. ................. *Check if E.P.R. valve setting can be achieved during freez

ing. If

............................................................................. not,

replace the cap tube.

Freezer refrigerant charge is low. ......................... *Refer to Troubleshooting Subsection 6.3.22

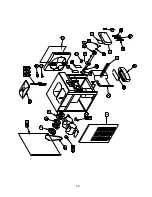

Summary of Contents for E131G

Page 1: ...Model E131G F131G SERVICE MANUAL Manual No 513537 3 Mar 2004...

Page 2: ......

Page 14: ...6...

Page 38: ...30 Figure 51 Power Board...

Page 39: ...31 Figure 52 Program Module...

Page 54: ...46...

Page 66: ...58...

Page 68: ...60...

Page 69: ...61 666786...

Page 70: ...62...

Page 71: ...63...

Page 72: ...64...

Page 73: ...65...

Page 74: ...66...

Page 75: ...67...

Page 76: ...68...

Page 77: ...69...

Page 78: ...70...

Page 80: ......