28

TIMERS

A maximum of 24 periods can be set on a timer.

All times have to be consecutive times. The

difference between two times must be at least 1

minute.

DOSAGE TIMERS

The timer output of a dosing timer is linked to a counter input to enable the water and/or feed intake to be

monitored. If significant variations occur, the control can generate a “dosing alarm” and stop the dosing of

water or feed.

Water timer

The water clock can be used to switch elements such as the water valves on or off. In

addition, there is the possibility of feeding back information on the actually administered water

amount to a counter input of the poultry computer (see Water dosing).

Water dosage

For water dosing, the water amount actually dosed is compared to the amount setting. Dosing

stops when the preset amount is reached, even if the stop time has not been reached yet. A

water dosing alarm is generated if the stop time is reached and the amount has not been

reached yet.

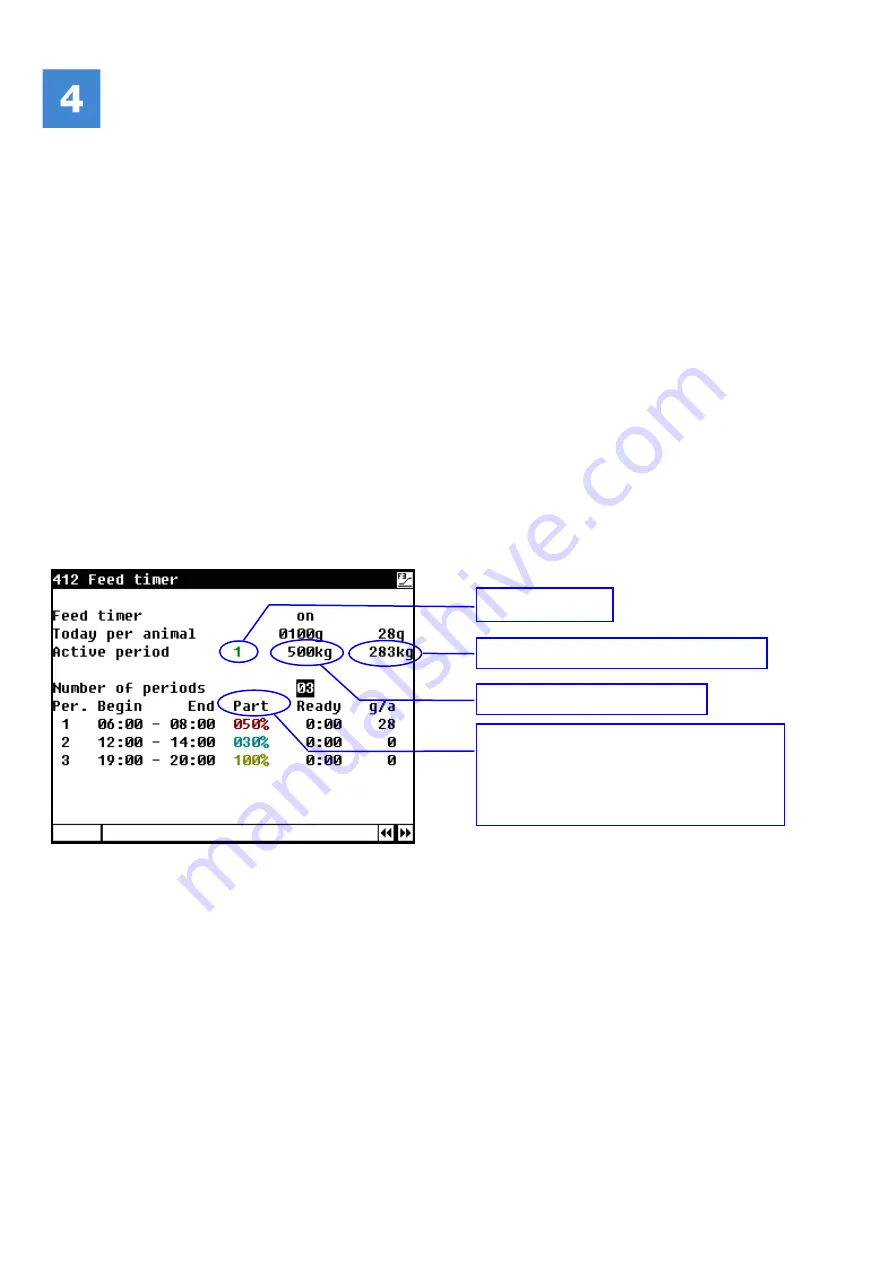

Feed timer

The feed clock can be used to switch elements such as the discharge augers on or off. In

addition, there is the possibility of feeding back information on the actually administered

amount of feed to a counter input of the poultry computer (see Feed dosing).

Feed dosage

For feed dosing, the amount actually fed is compared to the amount setting. Feeding stops

when the preset amount is reached, even if the stop time has not been reached yet. A feed

dosing alarm is generated if the stop time is reached and the amount has not been reached

yet.

Water and feed dosing make use of the number of animals present in the house. The number of animals is

determined at the start of the first actual dosing period, in order to calculate the total amount to be dosed. If

the number of animals changes in the meantime (due to animals dying, being removed or added) this no longer

affects the calculation.

The amount to be dosed is calculated between two periods.

WITH

“Auto. partition period”

- The total daily amount is divided over the preset number of

periods.

WITHOUT

“Auto. partition period”

- An error message will be generated if the sum of the

percentages set under “Part” is less than 100%.

If you enter 100% for the last period under “Part”, the

shortage of the prior periods

will be corrected in the last

dosing period

.

The dosed amount per period is listed under the last column (ml/d or g/d). If the amount to be dosed is

reached within the period, the time when the cycle has ended is shown under “Ready”.

If something has gone wrong in previous cycles, this will be corrected in the last cycle.

Active period

Already dosed in active period

Yet to dose in active period

If “Auto. partition period” has been

switched off

by your installer, you can

manually divide the total daily amount of

the feed etc. over the preset number of

periods.