Sterling Power Products

Copyright

Miscellaneous information

Battery temperature sensing:

Simply connect one of the enclosed temperature sensors

to a battery terminal post (negative or positive) and to the

2x small terminals marked battery temperature. There is

no polarity on these wires. The output voltage will be

reduced in accordance with manufacturer’s battery

charging temperature curves and, in the event, of the

battery temperature increasing due to battery failure. If it

exceeds 60 deg C, which is a major problem, the unit will

switch off the charging.

There is a power / temperature reduction algorithm which

will reduce the units output if the temperature rises to:

Battery Temperature: 65 degC

Charger Temperature: 90 degC

Start up and test procedure (x2 for 24V)

When the unit is first connected, it will run the start up

procedure as long as the battery is above about 6V. After

the start up procedure (if the input voltage is still low) the

unit goes onto sleep mode (all lights off). The unit will

remain in sleep until the input voltage exceeds 13.3V ( x 2

for 24V) this then activates the unit.

On normal operation:

when input voltage over 13.3V (x 2

for 24V).

The blue LED will light up showing constant current

charging, then after 1-8 hours (depending on state of

batteries etc. The blue and yellow indicating absorption

time 1 then yellow indicating absorption time 2, then green

for float (battery charged).

If on start up nothing happens:

Test the battery voltage. It should be above 13.3V, to see

the unit working start up the engine and ensure you are

getting at least 13.5V at the battery. If you are getting at

least 13.3V (at the unit) and there is nothing working then

the unit is defective. If you are not getting 13.3V then the

fault is on you power supply.

Fan replacement.

The main electrical box is IP68 i.e. it can be totally

submerged in water. However, the fan is IP55 which

cannot, so, in the event of the fan being destroyed simply

replace it. These small 40 mm fans are easily found and

are low cost to replace. Simply fit the correct DC voltage (

marked on the fan fitted ) and replace the unit.

What is regenerative braking?

Regenerative braking fix ( function 1+ 3 )

A new, very serious, issue for auxiliary charging systems

has now been introduced in a lot of vehicles and small

vans, it is called

It is a great idea as

regenerative braking.

far as the primary vehicle is concerned as it adds extra

MPG to the vehicle’s specification. However, it is an

unmitigated disaster as far as the auxiliary battery

charging system is concerned.

In order to increase efficiency of vehicle’s fuel

consumption, on vehicle’s start up, the idea is to only

charge the battery with enough power to safely restart

the engine. Once this has been achieved after a few

minutes then the alternator drops its voltage from

about 14.8V to about 12.6V leaving "space" in the

battery. The idea is that, at 12.6V, the alternator has

sufficient voltage to power the engine systems without

accessing the battery power, yet, not enough voltage

to charge the battery fully.

When the brakes are applied on the vehicle the

alternator’s voltage ramps up quickly to boost large

amounts of power into the space left in the battery.

This loads up the alternator which helps out the

vehicle’s braking and adds a spurt of power to the

batteries. Once the braking is removed then the

voltage drops again and that "free" power boosted into

the batteries is then used by the vehicle. Once it has

used up the 12.6V the alternator simply takes over.

This is great for the primary vehicle and does what it

says it does but means the auxiliary battery system

simply cannot get effectively charged.

The solution

is our new Battery to Battery charger. As

mentioned, it has both an auto setting and an ignition

setting. If you have a regenerative braking system

simply select the ignition setting and, even when the

vehicles electrics drops to 12.6V ( or lower ), we simply

take that voltage and boost it up into your auxiliary

battery system ensuring steady power charging

regardless of the vehicle’s voltage variations.

Page 8

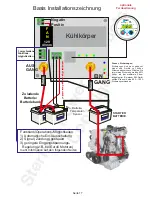

battery temp

sensor

Temperature sensor

Not obligatory to connect.

If you wish to install, connect the temp sensor to the

negative of the domestic / aux. batteries.

When temp sensor senses the temperature lower

than 20Deg C the voltage shall go up on the charger’s

output and when the temperature is higher than

20Deg C the voltage.

Sensor shall trip the charger if the temperature of

battery >55DegC.