Note corresponding coloured labels

instALLAtion ProCedure

Be aware that the system you are installing may differ from the example below. A major point of difference is

that there may be 2 control units supplied. This is the case for example for dispensers with 3 taps, or systems

where 2 dispensers connect to a single chiller. The installation process for the second controller is the same as

shown below.

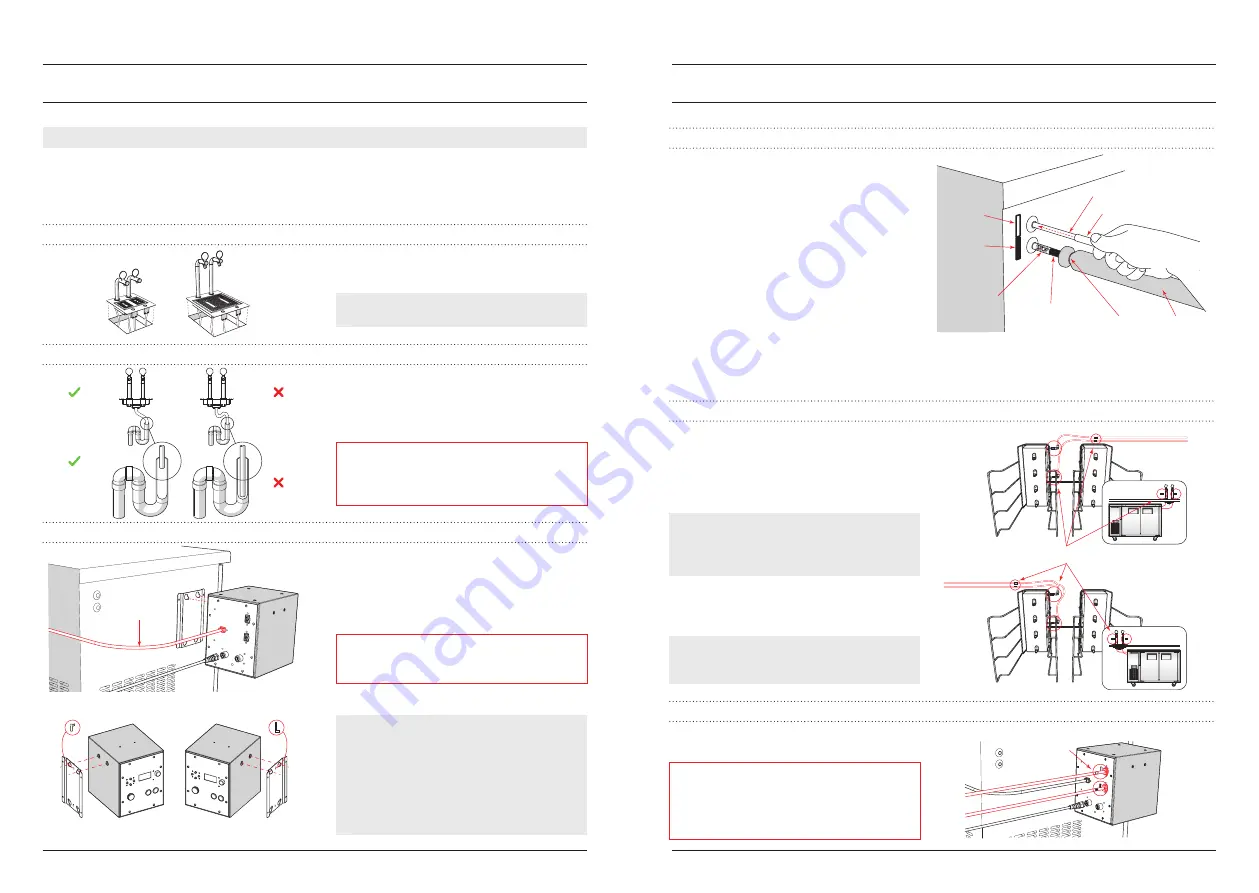

steP A - PLACe disPenser into the hoLe in the benCh

1. Uncoil the fluid product lines and data cables;

2. Lower Dispenser into the hole in the bench.

NOTE: The Dispenser will be set in place with

silicone or similar sealant in Step G.

steP b - ConneCt drAin hose

1. Push the drain hose onto the barb connector

underneath the sink and attach hose clamp;

2. Route the drain hose to a drain and cut hose

to length.

IMPORTANT:

For good drainage ensure adequate

fall and avoid sags in the hose. Ensure the end of

the drain hose cannot become submerged in the

drain.

steP C - Mount ControL unit And ConneCt ControL to PuMP CAbLe

1. Mount the Control Unit on the Control Unit

mounting bracket;

2. Uncoil the Control to Pump cable from the

rear of the Chiller and connect to the rear of

the Control Unit;

IMPORTANT:

To avoid malfunction ensure the

small catch on the male connector clips over the

retaining lug on the female connector.

3. Push the Chiller into place.

NOTE: Freepour generally ships with the Control

Unit mounting bracket and Control to Pump cable

set for a LHS installation. If the Control Unit is to

be set on the RHS of the Chiller or elsewhere the

Control Unit mounting bracket can be removed

from the Chiller and repositioned. The Control to

Pump cable can also be rerouted in the conduit on

the rear of the Chiller.

Installation Overview & Procedure

l

13

12

l

Installation Overview & Procedure

steP d - ConneCt FLuid ProduCt Lines to ChiLLer

1. Feed the blue protective sleeves over the fluid

product lines. Push the sleeves firmly up to

the fitting at the base of the tap. Observe the

stickers on the protective sleeves showing the

tap and Chiller ends of the sleeve;

2. Feed insulation over the fluid product lines.

Fasten in place with cable ties at both ends;

3. Punch out the centre of the rubber openings

in the side of the Chiller (inside and outside)

and push the fluid product lines through

the openings until the STOP sticker on

the protective sleeve contacts the rubber

opening. It can be helpful to wet the product

lines with water and dishwashing soap before

pushing them through the openings.

steP e - ConneCt FLuid ProduCt Lines inside ChiLLer

To account for all Freepour variants, fluid product

lines are supplied long and need to be cut before

connecting to the manifold inside the Chiller.

1. Determine the length for the fluid product

lines inside the Chiller and cut them to length;

NOTE: The length of the fluid product lines inside

the Chiller is correct when they are not too long

and risk being kinked inside the Chiller and not

too short making connection difficult.

2. Plug '

A'

fluid product line into the top

connector on the manifold and '

B'

fluid

product line into the lower connector.

NOTE: Ensure that the fluid product lines are

pushed FULLY into the fittings in the side of the

manifold so this connection does not leak.

steP F - ConneCt dAtA CAbLes

1. Connect the data cables (mentioned in STEP

A) to the rear of the Control Unit.

IMPORTANT:

Ensure the small catch on the male

connector clips over the retaining lug on the

female connector. If this catch does not engage,

the connector may slowly uncouple and cause the

machine to malfunction.

Control

to Pump

cable

Mounting

bracket

Drain hose

not sagging

Drain hose

correct length

Drain hose

sagging

Drain hose

too long

Tap A

coloured label

Tap B

coloured label

Coloured labels are used to identify all fluid and data connections.

Ensure you connect fluid lines and data cables into connectors

with corresponding coloured labels.

Cable tie

Tap B

coloured label

Insulation

STOP sticker

on protective

sleeve

Protective sleeve

Fluid product line

Note corresponding

coloured labels

Summary of Contents for Freepour

Page 16: ......