DXM100 MANUAL

2

118147-001 Rev. D

Remote Programming:

Allows remote programming of

the Output voltage, current, filament limit and preheat level

via the USB, Ethernet or RS232.

X-ray Enable/Interlock:

In local mode,

allows remote

ON/OFF control of the high voltage. In remote mode, the

hardware based dry contact closure must be closed in

order to enable the high voltage via the USB, Ethernet or

RS232.

1.3 System Status and Fault

Diagnostic Display

If a fault occurs, the power supply will revert to the

Shutdown mode indicated by extinguishing of X-ray ON

led and via RS-232 as HV OFF. To reset a fault in local

mode the enable must be reset. To reset a fault in remote

mode a HV ON command must be sent via the RS-232,

USB or Ethernet.

•

OVER CURRENT FAULT:

Indicates the over

current protection circuitry has caused the high

voltage to turn off. This fault will occur if the output

current exceeds 110% of full scale or 110% of current

program value. This fault is indicated by illumination

of over current led status on the front cover and via

RS-232, USB or Ethernet as Over Current.

•

OVERVOLTAGE:

Indicates the over voltage

protection circuitry has caused the high voltage to

turn off. This fault will occur if the output voltage

exceeds 110% of full scale or 110% of program

value. This fault is indicated by over voltage led

status on the front cover and via the RS-232, USB or

Ethernet as Over voltage.

•

ARC FAULT

: Indicates that an arc has occurred.

When a single arc occurs, the high voltage will be

quenched for 150ms and the Arc Fault led will

illuminate for 1 second and be reported via the digital

interface for 1 second as arc fault. If 4 arcs occur

within 10 seconds a HVPS fault will occur and the

HVPS will be shutdown. This fault is indicated by

illumination of Arc Fault led status on front cover and

via RS-232, USB or Ethernet as arc fault.

•

UNDER VOLTAGE:

Indicates a failure in the

voltage regulation circuitry. This fault occurs when

there is a lack of output power to maintain regulation

and will result in shutdown of the HV. This fault will

occur if the output voltage less than 10% below the

program value. This fault is indicated by illumination

of under voltage led status on the front cover and via

RS-232, USB or Ethernet as under voltage.

•

UNDER CURENT:

Indicates failure in the current

regulation circuitry. This fault occurs when the

allowable percentage of error between actual and

programmed emission current is exceeded. This fault

will not cause a shutdown of the HV. This fault will

occur if the output current less than 10% below the

program value. This fault is indicated by illumination

of under current led status on front cover and via RS-

232, USB or Ethernet as under current.

•

OVER TEMPERATURE:

Indicates either a failure

in the cooling system that would cause the internal

heat sink temperature to exceed it’s operating range

or the ambient temperature to exceed 40degC,

resulting in shutdown of HV. This fault is indicated

by over temperature led status on the front cover and

via RS-232, USB or Ethernet as over temperature.

•

Filament Protection:

If the output voltage goes

below 30% of full rating the filament power will be

disable to protect the filament in the users X-ray tube,

but the filament preheat will still be active. This will

cause an undercurrent fault.

•

PS Fault Indication:

PS Faults an open collector

output with a 1k ohm series impedance on J2-1,

indicates that a fault has occurred. High = no faults

•

X-ray On Indication:

X-ray On Signal is an open

collector output a 1k ohm series impedance on J2-14,

indicates X-ray status. High = X-ray Off, Low =X-

ray On

•

X-ray On LED:

when the high voltage status is

“On” state it is indicated by X-RAY ON led status on

the front cover

•

Power On LED:

when the input power is applied to

the unit it is indicated by PWR ON led status on the

front cover

1.4 Interpreting the Model Number:

The model number of the power supply describes its

capabilities. After the series name is:

(1)

The maximum voltage in kilovolts.

(2)

The polarity of the output – positive (P), or

negative (N).

(3)

The maximum output in watts.

(4)

Custom “X” number representing details listed in

a separate specification control drawing.

Summary of Contents for DXM100 Series

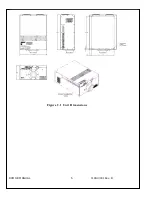

Page 11: ...DXM100 MANUAL 5 118147 001 Rev D Figure 2 1 Unit Dimensions ...

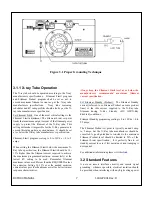

Page 16: ...DXM100 MANUAL 10 118147 001 Rev D Figure 3 3 Local Programming Via External Voltage Source ...

Page 17: ...DXM100 MANUAL 11 118147 001 Rev D Figure 3 4 Remote Monitoring ...

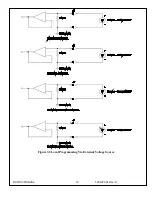

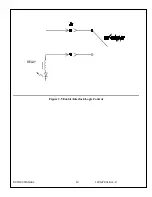

Page 18: ...DXM100 MANUAL 12 118147 001 Rev D RELAY Figure 3 5 Enable Interlock Logic Control ...

Page 37: ...118142 001 Rev B Page 13 of 104 Figure 9 Web Page 1 Contact Information ...