NOTICE: Do not shorten sound attenuating tube

length. The result would be unacceptable noise.

Push the free end of the sound attenuating tube through

the 4" hole until the two toggle springs on the room

terminator snap into place.

Center the two spring clips on a line parallel to the direc-

tion of the tubing routing from the room terminator (see

Figure 2.16). This is important since the weight of the

tubing will have a tendency to cause a part of the termi-

nator to pull away from the ceiling if the clips do not run

parallel to the tubing run.

Then tighten the screws (attached to the terminator) until

the terminator is snug against the ceiling or floor.

Do not

overtighten.

For installations with floors or ceilings

which are thicker than normal, field supplied longer

toggle screws or special mounting plates may be

required.

13

4" MINIMUM RADIUS

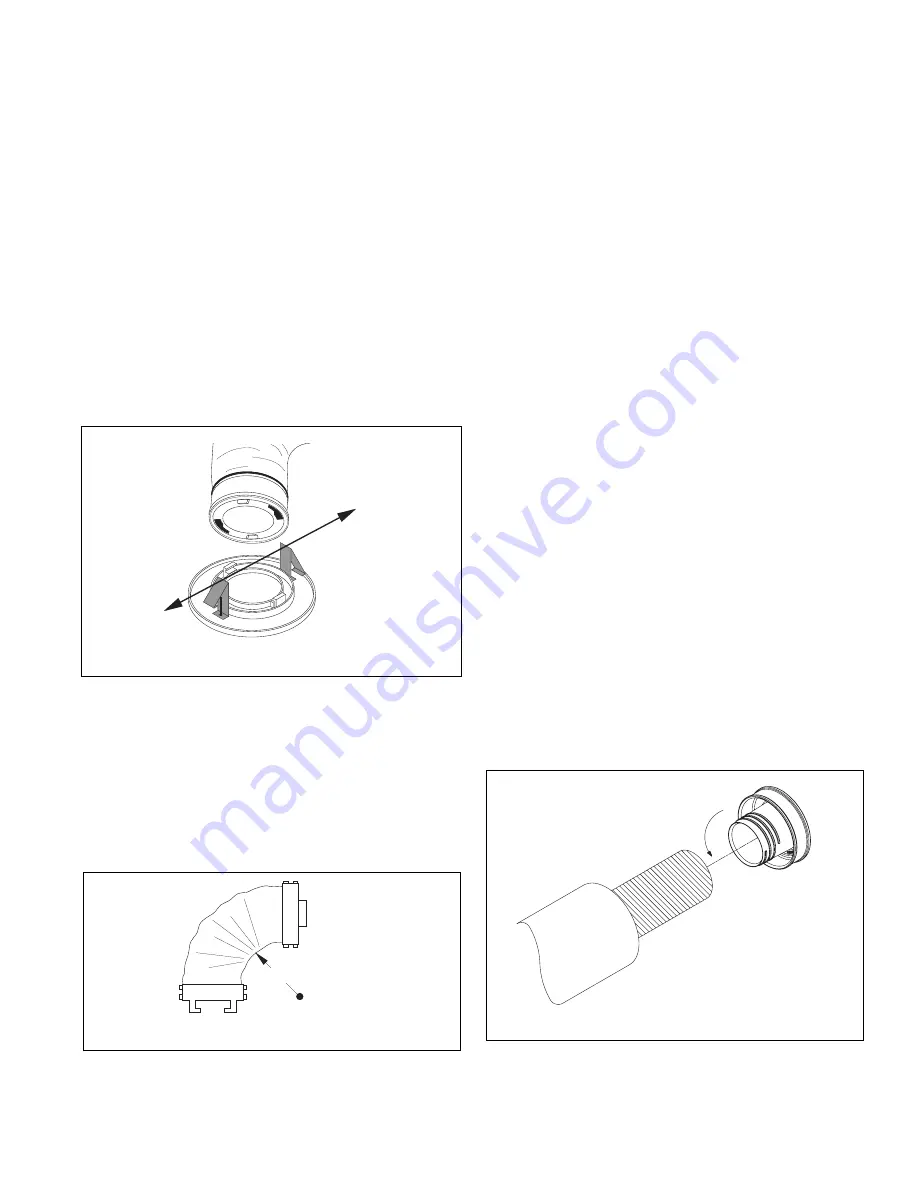

FIGURE 2.17: MINIMUM TUBING BEND

TUBING ROUTING

FIGURE 2.16: POSITIONING ROOM TERMINATOR

Supply Tubing Installation

Kwik-connects and balancing orifices are provided in the

Installation Kits. Plenum take-offs, gaskets and fasteners

are supplied in the separate plenum take-off kit.

Avoid sharp bends in the supply tubing (as well as the

sound attenuating tubing). The minimum radius bend is

4" (see Figure 2.17); however, wherever possible, hold to

a larger radius.

TWIST

FIGURE 2.18: KWIK-CONNECT INSTALLATION

At the plenum, all supply tubing connections must be a

minimum of 18" from any plenum tee, plenum elbow or

the fan coil unit.

Individual supply tubing runs must be a minimum of

6-feet, even if the distance between the sound attenuat-

ing tubing and plenum is less than 6 feet.

Supply tubing comes in 100-foot sections (R8 tubing

comes in 50-foot sections and R6 tubing comes in 75-

foot sections) and may be cut to length with a knife or fine

tooth hacksaw.

For each supply tubing run, estimate and cut the length

of tubing that will be needed between the plenum and

sound attenuating tube. At the open end of the supply

tubing a kwik-connect will be installed (see Figure 2.18).

First, push back the cover and the insulation exposing

approximately 4" of the inner core. Fold in any tails or

frays that may be present after cutting the supply tubing.

Second, hand compress the corrugations until they are

densely compacted 1

1

⁄

2

" to 2" from the open end of the

supply tube. Third, thread kwik-connect into the inner

core until snug. Fourth, pull the insulation and cover for-

ward and tuck it into the deep groove on the back side of

the kwik-connect. Fifth, wrap the connection securely

with UL181 approved tape.

When finished, simply twist together (see Figure 2.19)

the kwik-connect on the sound attenuating tube, and

wrap the connection securely with tape.

After attaching the supply tubing to the sound attenuating

tube, bring the open end of the tube to the plenum.

To cut a hole in the plenum, refer to duct installation

instructions supplied with fan coil unit. Sheet metal duct

requires a 2

1

⁄

16

" hole.

Summary of Contents for ESPV2-109

Page 11: ...11 FIGURE 2 9 MODEL ESP V WIRING SCHEMATIC...

Page 26: ...26 NOTES...

Page 27: ...27 NOTES...