BT-T080R User’s Manual

- 20 -

1

)

Paper roll with thermal layer outward

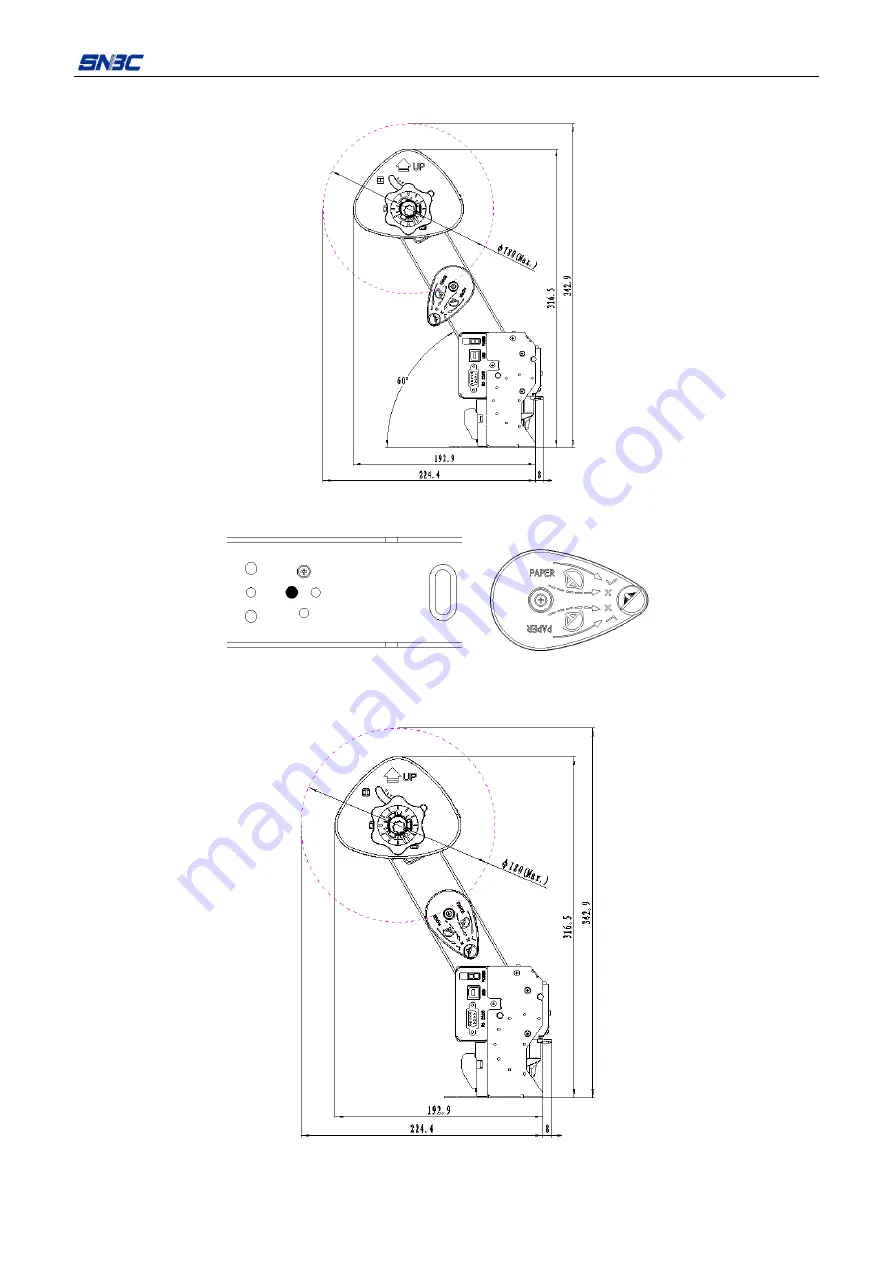

Figure 4.3.9 Module installation setting and size

Position 1 for installing buffer

Buffer shaft position 1

2

)

Paper roll with thermal layer inward

Figure 4.3.10 Module installation setting and size