SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

VERSION 11/2016

FS351SP

Propane

11

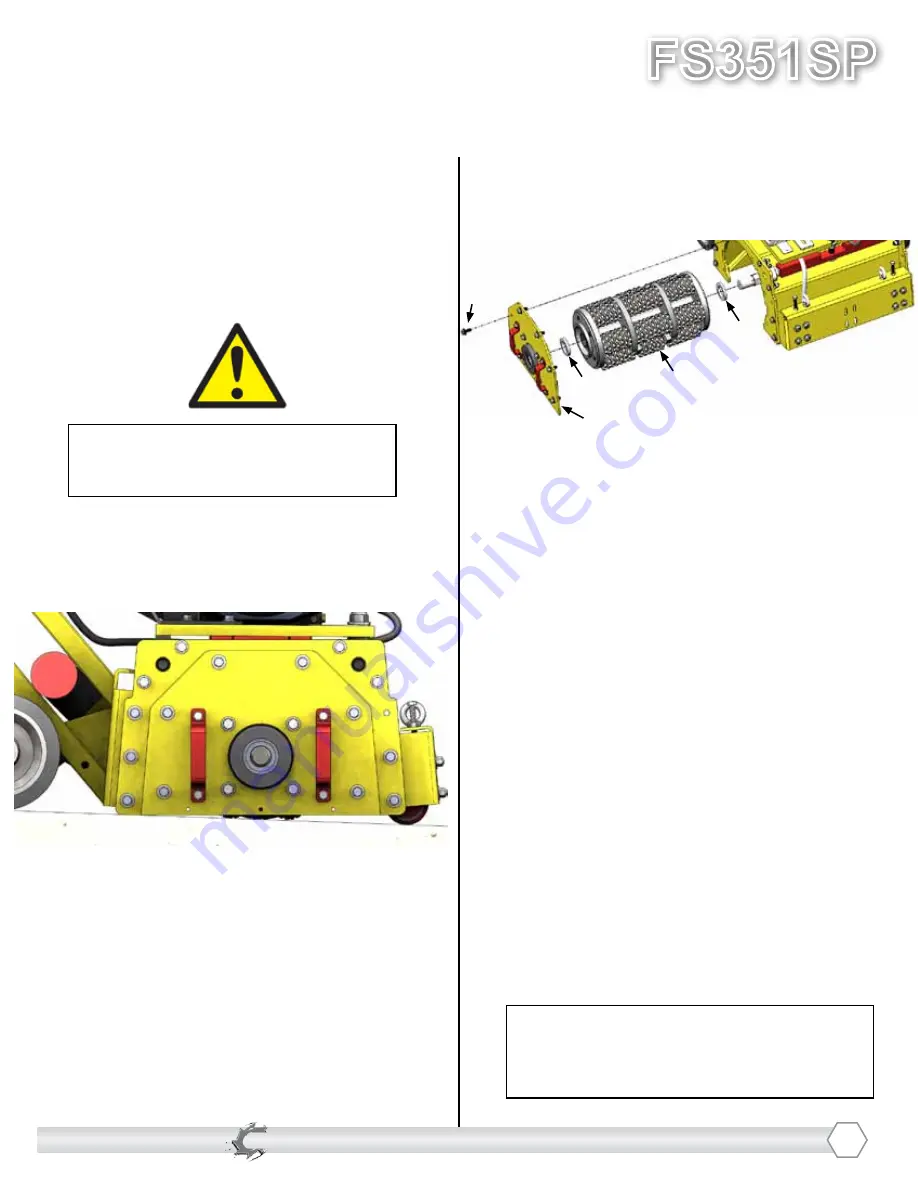

DRUM RePlaceMent

Drum replacement is easy and requires a

few hand tools.

1. 9/16” socket or wrench

2. Rubber mallet

Before beginning servicing on any

propane-powered unit,

DISconnect SPaRK PlUg WIReS!

1. lower the machine so the cutter drum

is resting on the ground. Do this with the

cutter height adjustment t-handle.

4. Slide out drum assembly. (use caution as

it is

HEAVY

)

2)

3)

4)

5. once the cutter drum is removed take to a

workbench for assembly.

a) Inspect condition of cutters,

spacers, shafts, bushings and drum.

6) Before replacing the drum onto hex shaft:

a) check that all bearings are in

good working order

b) Remove dirt and material build-up

from inside drive carriage and drum.

c) lubricate shaft and drum bushings

with synthetic dry lube.

d) Make sure to replace drum spacers

and that they are properly seated.

7) align and slide drum back onto the hex

shaft.

8) Replace side plate (lift-up and lock into

place) over hex shaft and secure hardware.

note: It is recommended that you use a

wooden board or something similar to place

under the drum before lowering the machine

to take the drum weight off the shaft which

makes it easier to align with side plate

2. Remove the six hex head cap screws

from the side plate using the 9/16” socket

or wrench.

3. Remove the side plate (this may require

the rubber mallet to break it loose)

*tIP: SMItH recommends owning an

extra drum loaded with cutters for

rapid job-site work flow.

6d)

6d)