-30-

No. TQ1230001-OM101-A

8.Precautions

8.1

Air supply

Warning

■

Use clean air.

It is recommended to use compressed air which purity class is 2:6:3 of ISO8573-1:2010. Supply air containing foreign

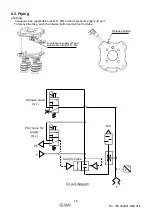

matter, water, oil, condensate, etc., can cause malfunction of the supply valve and release valve. So, install air

preparation equipment on the upstream side of the product (refer to the piping example below) and perform

maintenance periodically to control the supply air properly.

Refer to "SMC Air Preparation System" for further details on compressed air quality.

8.2

Vacuum gripper unit precautions

■

Mounting

Warning

1)

Tighten to the specified tightening torque.

If the tightening torque is exceeded, the product, the mounting screws, brackets and the pressure switch

can be broken. Insufficient torque can cause displacement of the product and the pressure switch from

each proper position and loosening of the mounting screws.

2)

Hold the product itself when handling.

Do not pull the M8 connector cable strongly or lift up the product by holding this cable. It can cause the

malfunction of the product.

■

Wiring

Warning

1)

Do not perform wiring while the power is on.

Otherwise damage to the solenoid valve or the internal parts of the pressure switch/sensor can result,

causing malfunction.

2)

Never disassemble the M8 connector cable or make any modifications including additional machining.

Doing so may cause human injury and/or an accident.

Caution

1) Avoid repeated bending, tensioning or external force to the M8 connector cable.

■

Piping

Caution

1) Preparation before piping

Before piping, perform air blow (flushing) or cleaning to remove any cutting chips, cutting oil, dust, etc. from

the piping.

2) Installation of tubing

・

Cut the tubing perpendicularly, being careful not to damage the outside surface. Use an SMC tube cutter TK-

Vacuum

gripper unit