-35-

No. TQ1230001-OM101-A

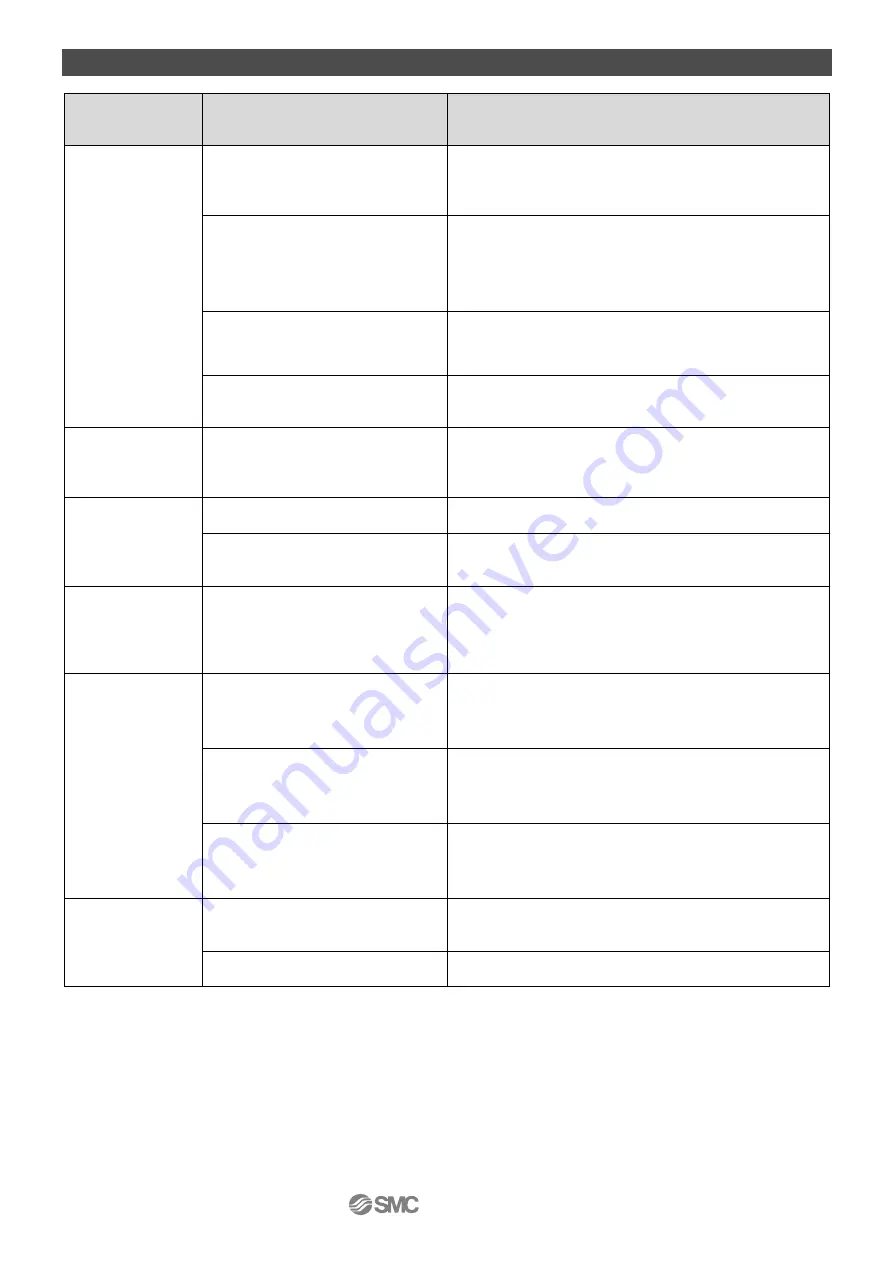

9.Trouble shooting

Condition &

Description of

improvement

Contributing factor

Countermeasure

Initial adsorption

problem

(During

trial

operation)

Adsorption area is small.

(Lifting force is lower than the

workpiece mass.)

Recheck the relationship between workpiece mass

and lifting force.

- Use a suction cup with a large adsorption area.

- Increase the quantity of suction cups.

Vacuum pressure is low.

(Leakage from adsorption

surface)

(Air permeable workpiece)

Eliminate (reduce) leakage from adsorption surface.

- Reconsider the shape of a suction cup.

Check the relationship between suction flow rate and

arrival pressure of vacuum ejector.

- Increase adsorption area.

Inadequate supply pressure of

vacuum ejector

Measure supply pressure in vacuum generation state.

- Use standard supply pressure.

- Reconsider compressed air circuit (line).

Clogging of vacuum ejector

(Infiltration of foreign matter during

piping)

Remove foreign matter.

Late vacuum

achieving time

(Shortening of

response time)

The set vacuum pressure for the

suction verification is too high.

Set to suitable setting pressure.

Fluctuation in

vacuum pressure

Fluctuation in supply pressure

Reconsider compressed air circuit (line).

(Addition of a tank etc.)

Vacuum pressure may fluctuate

under certain conditions due to

ejector characteristics.

Lower or raise supply pressure a little at a time, and use

in a supply pressure range where vacuum pressure

does not fluctuate.

Occurrence of

abnormal noise

(intermittent noise)

from exhaust of

vacuum ejector

Intermittent noise may occur

under certain conditions due to

ejector characteristics.

Lower or raise supply pressure a little at a time, and

use in a supply pressure range where the intermittent

noise does not occur.

Adsorption

problem over time

(Adsorption

is

normal during trial

operation.)

Clogging of the silencer

Replace the silencer.

Add a filter to supply (compressed) air circuit.

Presence of foreign matter in the

ejector.

Remove foreign matter.

Replace the ejector

Add a filter to supply (compressed) air circuit.

Cup (rubber) deterioration,

cracking, etc.

Replace cups.

Check the compatibility of vacuum cup material and

workpiece.

Workpiece is not

released.

The increase of stickiness due to

the wearing of the cup (rubber).

Replace cups.

Check the compatibility of the cup material and

workpiece.

Vacuum pressure is too high.

Set the vacuum pressure to the minimum value

necessary.