- 21 -

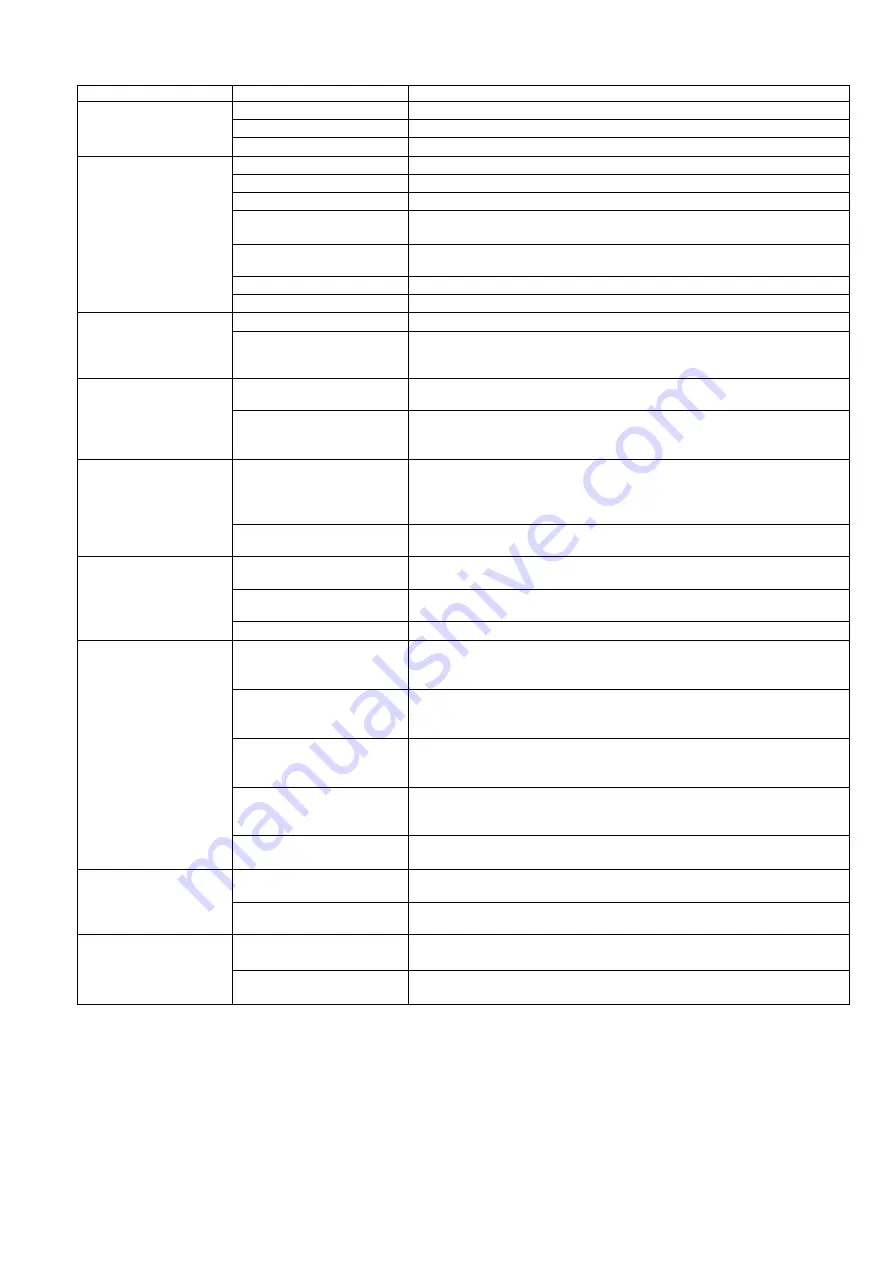

9. Troubleshooting

Detail of trouble

Cause

Countermeasure

Operation is not

smooth

1. Lubrication failure

・

Clean components and apply specified grease to them.

2. Piston rod deformation

・

Replace cylinder and adjust load and position.

3. Insufficient air pressure

・

Supply an appropriate amount of pressure.

Output is decreasing

1. Piston seal air leakage

・

Replace piston seal.

2. Rod seal air leakage

・

Replace cylinder

3. Air pressure decrease

・

Review the amount of pressure and capacity of the pressure source.

4. Insufficient air flow

・

Maintain and/or clean air passages. Air flow might have decreased

due to deformation and/or foreign matter.

5. Incorrect cylinder

mounting position

・

Mount cylinder correctly to avoid excessive strain.

6. Piston rod deformation

・

Replace cylinder and adjust load and position.

7. Lubrication failure

・

Refer to “Operation is not smooth” above.

Piston operates too

fast

1. No speed controller

・

Use a speed controller appropriate to the cylinder size.

2. Precise adjustment of

speed controller is

insufficient

・

Select an appropriate speed controller to secure required operating

speed referring to speed controller flow rate characteristic curves.

Piston operates too

slowly

1. Directional control valve

is too small

・

Use a larger size of valve.

2. Large resistance of

equipment in the system

・

Use valves and other equipment of appropriate sizes. Do not forget

to check piping and fitting sizes. Use appropriate piping and

equipment on the outlet side.

Cylinder occasionally

stops operating

1. Very low speed

operation

・

Operate cylinder within the specified range of speed. Very low speed

operation reduces the pressure difference between inlet side and

outlet side of the cylinder to almost zero, which may lower sealing

ability and result in malfunction.

2. Defective equipment

other than cylinder

・

Examine all the equipment used in the system one by one.

Cylinder stops

operating

1.

Piston seal damaged

・

Replace piston seal if air comes out from exhaust port of valve

continuously.

2. Defective equipment

other than cylinder

・

Examine all the equipment used in the system one by one.

3.

Insufficient air pressure

・

Supply an adequate amount of pressure.

Piton rod deformed or

broken

1. High speed operation

・

Replace cylinder. Operate it within the specified range of speed. High

speed operation may result in cylinder deformation or breakage due

to impact force.

2.

Abnormal external force

applied

・

Replace cylinder after removing mechanical interference, unbalanced

load or excessive load which may cause cylinder deformation or

breakage.

3. Impact of pallet while

the lever is standing

erect

・

For a lever with built-in shock absorber type, do not allow the next

pallet to collide while the lever is standing erect. Otherwise, all

energy will be applied to the cylinder body.

4. External force applied

from the opposite side

when the lever is locked

・

For cylinders with locking mechanism, do not apply an external

force from the opposite side when the lever is locked.

5. Shock absorber

adjustment problem

・

Adjust the shock absorber to the optimum absorption position to stop

work pieces gently.

Cylinder speed cannot

be controlled with

speed controller

1.

Unsuitable speed

controller

・

Select an appropriate speed controller for the desired operating

speed.

2. Defective speed

controller

・

Replace speed controller.

Cylinder stick-slip

operation

1. High load factor

・

Increase operating pressure.

・

Use cylinder with larger bore.

2. Meter-out circuit not

used

・

Control operating speed with a meter-out circuit. Meter-in circuit

may make operation unstable at low pressure and speed.

Summary of Contents for RS2H Series

Page 24: ...23...