Wersja 1.00

Data edycji: 16.09.2022 r.

Strona 34 z 35

Dokumentacja techniczno-ruchowa

KWP-P-E

In order to check the proper functioning of fire damper, in particular:

a.

Check the fire damper without disconnecting the supply voltage from the actuator.

b.

The opening and closing test should be carried out by positioning the baffle

from control system („open” and

„closed” position read on the position indicator located on the actuator).

c.

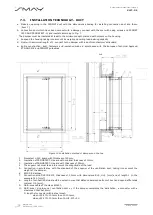

Take off inspection hatch, make a visual inspection of the interior of fire damper, determine the condition of the

baffle and seal, whether there are no damage or dirt that could block the fire baffle during closing. After an

inspection put the inspection hatch back.

d.

Put the inspection hatch back. Leave the fire damper in the right work position.

e.

Make a control protocol.

Fire damper can be cleaned with a dry or damp cloth. Dirt and other pollution can be cleaned with generally available

cleaners. Do not use aggressive, caustic cleaners and sharp tools.

Table 5.Diagnostic card

Diagnostic card

No.

Symptoms of

malfunction

Causes of malfunction

How to remove malfunction

1

No signaling

opening/closing fire

damper

1. Failure to fully open the

baffle (wrong connected

ventilation duct)

2. Improperly connected wires

of limit switch

3. Damaged actuator

1. Removing the cause of blocking

baffle

2. Correct wiring

3 . Replacing the actuator with a

new one (after consulting with fire

damper`s manufacturer)

2

No actuator response

after connecting

power

1 .Damaged actuator

2. Damaged temperature

sensor

3. Locked baffle

1. Replacing the actuator with a

new one (after consulting with fire

damper`s manufacturer)

2. Replacing the temperature

sensor to a new one

3 .Removing the cause of blocking

baffle

3

No possibility of

opening the fire

damper with actuator

by key

1 .Broken mechanism in the

actuator (too rapid rotation)

2.Locked baffle

1. Replacing the actuator with a

new one (after consulting with fire

damper`s manufacturer)

2. Removing the cause of blocking

baffle