Wersja 1.00

Data edycji: 16.09.2022 r.

Strona 27 z 35

Dokumentacja techniczno-ruchowa

KWP-P-E

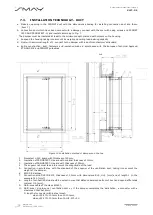

STEP 2:

a.

Fix the gasket on insulating spacer of one of adjoining fire dampers (position (2) in the Figure 13).

b.

Put non-combustible mineral wool into recess in upper surface of the fire damper C and fire damper D. The

thickness of mineral wool should be twice as the thickness of the recess in upper surface of the fire dampers in

order to fill the whole free space between the fire dampers C and D and the fire dampers A and B, as shown in

(w1).

NOTE: The alternative way of wool mounting is to use two layers of wool with thickness of 30mm. In this case,

apply the fire resistant PROMASTOP-Coating with width of 50 mm. The mass is placed between the strips of

wool and between wool and damper housings.

c.

Place the set of fire dampers A and B on the set of fire dampers C and D and assemble them together on the

front and back with use of perforated assembly strips (5) and self-tapping screws M6x10 (6), which should be

tightened into the openings in fire damper body. In order to carry out the correct assembly, 4 self-tapping

screws should be used per each assembly strip with length of 1200 [mm].

d.

The empty space between joint of the bodies of fire dampers A, B and fire dampers C, D should be filled with

non-combustible mineral wool (as shown in (w2)).

NOTE: The alternative way of wool mounting is to use two layers of wool with thickness of 30mm. In this case,

apply the fire resistant PROMASTOP-Coating with width of 50 mm. The mass is placed between the strips of

wool and between wool and damper housings.

e.

The place of sealing the top of the battery with mineral wool should be sealed with aluminum tape

(7)

.

Installation of KWP fire dampers batteries in rigid wall compartment (Figure 15 to 18)

a.

Make an opening in the wall with dimensions depending on the battery size and its arrangement:

▪

For vertical battery consisting of two KWP fire dampers: (B1+120)x(H1+H2+180) (Figure 15),

▪

For vertical battery consisting of three KWP fire dampers: (B1+120)x(H1+H2+H3+240) (Figure 16),

▪

For horizontal battery consisting of two KWP fire dampers: (B1+B2+180)x(H1+120) (Figure 17),

▪

For battery consisting of four KWP fire: (B1+B2+180)x(H1+H2+180) (Figure 18),

b.

Put the battery of fire dampers into the installation opening on depth marked by undercuts on the damper body

[dimension 60mm). From one side fix it with suspension Z1, and from other side, fix it to ventilation duct

suspended on suspension Z2 according to the figure).

NOTE: Fixing of the ductwork has to cover the weight of the battery of fire dampers. Specifically the bolts,

anchors, installation frame of the duct and screws used to join the duct with battery of fire dampers should be

taken into account. If there is no possibility of ensuring the safe suspension of the battery of fire dampers during

installation, the battery should be supported from the bottom side.

c.

After setting the fire damper as described, fill the gap between the fire damper and the wall with cement,

cement-lime mortar or concrete or PROMASTOP MG III of production of the PROMAT company.

d.

After 72 hours from the finish of assembly, you can disassemble suspensions.

REMARKS:

a.

Install the fire damper in such way, that the damper blades would be in horizontal position.

b.

Fire damper cannot be the support for the constructed wall.

c.

Ductwork cannot be the load for the fire damper, ductwork suspensions have to provide full load capacity.

d.

Ductwork suspensions fixed to the fire damper have to be made in accordance with the ductwork manufacturer

instructions.

e.

Selection of mounting rails should be performed in accordance to the guidelines provided by the manufacturer of

suspensions, considering weight and arrangement of the battery of fire dampers.

f.

In place of suspensions Z1, Z2 and cement mortar, mounting brackets may be applied! Paying special attention

for immobilization of the fire damper).