Wersja 1.00

Data edycji: 16.09.2022 r.

Strona 15 z 35

Dokumentacja techniczno-ruchowa

KWP-P-E

ATTENTION:

a.

The damper must be installed in such way, that the axis of baffle must be in horizontal or vertical position,

b.

Damper can not be used as formwork for the wall,

c.

Ventilation ducts should be installed that they cannot put any load on the damper, their suspension must ensure

their full load capacity,

d.

The suspensions of the ventilation ducts connected to the dampers batteries must be made in accordance with

the instruction of the manufacturer of ventilation ducts,

e.

In place of Z1 and Z2 suspensions, which are installed for the time of assembly of the damper and in place of

mortar binding, it is possible to use mounting brackets, paying attention to the immobilization of the damper.

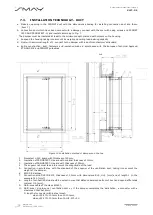

7.1.

INSTALLATION TECHNOLOGY

–

RIGID WALL

f.

Make an opening in the wall

with the 100 [mm] (acceptable 80 ÷ 120 [mm]) greater than the nominal

dimensions of the fire damper = B+100 and H+100.

g.

Put the closed fire damper into the installation opening on the depth marked by undercuts on the damper body

(dimension 60 mm), from one side fix it with suspension Z1, and from other side fix it to the ventilation duct on

Z2 suspension.

h.

After setting the fire damper as described, fill the gap between the fire damper and the wall with cement,

cement-lime mortar, concrete, or PROMASTOP MG III of production of the PROMAT company.

i.

After 48 hours from the installation, the suspensions and supports used during installation of the fire damper,

may be removed.

Figure 3. Correct preparation of the damper for installation (using mounting wedge)