Section 3 - Operation

Diagrams

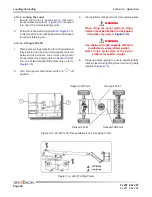

Diagram 3.5 Axle Oscillation Diagrams

WARNING

Do not raise the platform in work mode if it is not on a firm level surface.

Axle oscillation free (travel mode) - drive speed 4.5 mph (7.2 km/h) max.

Axle oscillation locked (work mode) - drive speed 0.5 mph (0.8 km/h) max.

Figure 3-28. Axle Oscillation - SJ 40T/61T

Axle oscillation free (travel mode) - drive speed 4.5 mph (7.2 km/h) max.

Axle oscillation locked (work mode) - drive speed 0.5 mph (0.8 km/h) max.

Figure 3-29. Axle Oscillation - SJ 45T/66T

SJ 40T & SJ 45T

SJ 61T & SJ 66T

Page 67

Summary of Contents for SJ45T

Page 12: ...Page 12 SJ 40T SJ 45T SJ 61T SJ 66T Notes ...

Page 42: ...Page 42 SJ 40T SJ 45T SJ 61T SJ 66T Notes ...

Page 68: ...Page 68 SJ 40T SJ 45T SJ 61T SJ 66T Notes ...

Page 104: ...Page 104 SJ 40T SJ 45T SJ 61T SJ 66T Notes ...

Page 105: ...Cancer and Reproductive Harm https www p65warnings ca gov WARNING ...

Page 106: ...www skyjack com elig lift løsninger av folk som bryr seg ...