48

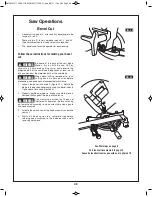

Bevel Cut

•

A bevel cut is made at 0° miter and any bevel angle in the

range of 0° to 45°.

•

There are two (2) factory set bevel stops at 0° and 45°.

(See Adjustment section if adjustments are required.)

•

The bevel scale faces the operator for easy reading.

Follow these instructions for making your bevel

cut:

Be aware of the path of the saw blade.

Make a dry run with the saw OFF by

conducting a simulated cutting cycle, and observe the

projected path of the saw blade. Keep hands at least six (6)

inches away from the projected path of the saw blade.

When bevel cutting remember to “lock”

cutting head in every position before

proceeding, so head does not unexpectedly shift in use.

1.

Loosen the bevel lock knob

1

(Figure 29). Rotate the

blade to the desired bevel angle using the bevel index

2

.

Tighten bevel lock knob (Figure 30).

2.

Properly position workpiece. Make sure work piece is

clamped firmly against the table and the fence.

Use clamping position that does not

interfere with operation. Before switching

on, lower head assembly to make sure clamp clears guard

and head assembly.

3.

Activate the switch. Lower the head assembly and make

your cut.

4.

Wait until blade comes to a complete stop before

returning head assembly to the raised position and/or

removing workpiece.

Saw Operations

FIG. 30

WARNING

!

WARNING

!

See Warnings on page 5

Voir les avertissements à la page 12

Consulte las advertencias que están en la página 19

2

FIG. 29

1

WARNING

!

SM 2610017175 08-11:SM 2610017175 08-11.qxp 8/2/11 11:24 AM Page 48