AIR-TO-WATER HEAT PUMP INSTALLATION MANUAL

silk screen

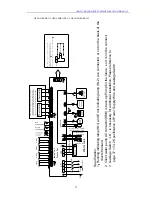

location

specification

AC-L -

live wire of power supply

N -

Neutral wire of power supply

PUMP1 X13

live wire of indoor water pump

PUMP2 X14

live wire of solar water pump

RUN X15

running indicator

HEAT3-L X16

e-heater of water tank

HEAT1-L X17

e-heater of indoor unit 1

HEAT2-L X18

e-heater of indoor unit 2

ERR X19

error indicator

2V1_OFF X5

Electric magnetic 2-way valve1 is normally closed.

2V1_ON X6

Electric magnetic 2-way valve1 is normally open.

2V2_OFF X7

Electric magnetic 2-way valve2 is normally closed.

2V2_ON X8

Electric magnetic 2-way valve2 is normally open.

3V1_OFF X9

Electric magnetic 3-way valve1 is normally closed.

3V1_ON X10

Electric magnetic 3-way valve1 is normally open.

3V2_OFF X11

Electric magnetic 3-way valve2 is normally closed.

3V2_ON X12

Electric magnetic 3-way valve2 is normally open.

T-SENSOR1 CN10

terminal of temperature sensor1

T-SENSOR2 CN11

terminal of temperature sensor2

T-SENSOR3 CN12

terminal of temperature sensor3

T-SENSOR4 CN13

terminal of temperature sensor4

T-SENSOR5 CN14

terminal of temperature sensor5

T-SENSOR6 CN15

terminal of temperature sensor6

DOOR-C CN23

Door detection input

OVC-HEAT3 CN28

e-heater of water tank adhesion-proof protection detector

OVC-HEAT1 CN26

e-heater of indoor unit1 adhesion-proof protection detector

OVC-HEAT2 CN27

e-heater of indoor unit2 adhesion-proof protection detector

IN-SW CN25

detection input of water flow switch

COM-MANUAL CN6

connect the wired controller

COM-OUT CN5

connect to outdoor unit

COM-BMS CN7

connect to remote controller

TR-OUT1 CN2

transformer output 1

TR-OUT2 CN3

transformer output 2

TR-IN CN1

220V in put of transformer

CN30 CN30

heavy-current interface of end controller

CN31 CN31

heavy-current interface of end controller

18.2 ELECTRIC WIRING WORK

18.2.1 Wiring Principle

①

General principles

Wires, equipment and connectors supplied for use on the site must be in compliance with

provisions of regulations and engineering requirements.

Only electricians holding qualification are allowed to perform wire connection on the site.

Before connection work is started, the power supply must be shut off.

Installer shall be responsible for any damage due to incorrect connection of the external

circuit of the unit.

Caution --- MUST use copper wires.

②

Connection of power cable to the electric cabinet of the unit

Power cables should be laid out through cabling trough, conduit tube or cable channel.

Power cables to be connected into the electric cabinet must be protected with rubber or

plastic to prevent scratch by edge of metal plate.

Power cables close to the electric cabinet of the unit must be fixed reliably to make the

power terminal in the cabinet free from an external force.

Power cable must be grounded reliably.

44

Summary of Contents for GSH-100ERA series

Page 2: ......

Page 49: ...AIR TO WATER HEAT PUMP INSTALLATION MANUAL GSH 120ERA 3 GSH 140ERA 3 GSH 160ERA 3 47 ...

Page 62: ......

Page 63: ......