2899

6

GB

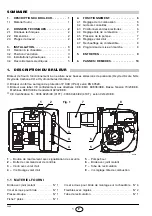

4.

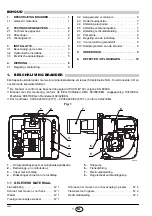

WORKING

4.1

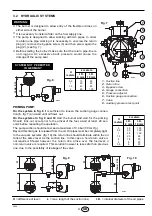

COMBUSTION ADJUSTMENT

In conformity with Efficiency Directive 92/42/EEC the application of the burner on the boiler, adjustment and

testing must be carried out observing the instruction manual of the boiler, including verification of the CO and

CO

2

concentration in the flue gases, their temperatures and the average temperature of the water in the boiler.

To suit the required appliance output, choose the proper nozzle and adjust the pump pressure, the setting of

the combustion head, and the air damper opening in accordance with the following schedule.

The values shown in the table are measured on SIME boiler (as EN 267).

They refer to 13% CO2 at sea level and with light oil and room temperature of 20 °C.

SIME BLUE MACK 1 burner leaves the factory set for the matching with the Rondò - Estelle 4 boiler and

Rondò B4 boiler.

SIME BLUE MACK 2 burner leaves the factory set for the matching with the Rondò - Estelle 5 boiler and

Rondò B5 boiler.

IMPORTANT:

Using Danfoss 60° H nozzles, you get the best emission values.

In field, it is advisable to use Danfoss 60°S nozzles in order to make the burner working more reliable in

time.

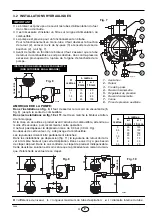

APPROXIMATE ADJUSTMENTS FOR INSTALLATION ON OTHER BOLERS

The values shown in the table are measured on a CEN boiler (as per EN 267).

They refer to 13% CO2 at sea level and with light oil and room temperature of 20 °C.

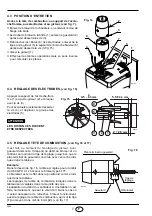

4.2

NOZZLES RECOMMENDED

Delavan tipo W;

Danfoss tipo S - H;

Fluidics tipo S F.

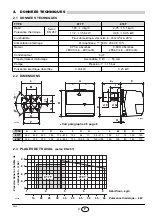

BOILER

BURNER

Nozzle

Pump

pressure

Burner

output

Comb. head

adjustment

Air damper

adjustment

Code

Model

GPH

Angle

bar

kg/h ± 4%

Set-point

Set-point

Rondò-Estelle 3

8099100

SIME BLUE

MACK 1

0.50

80° S

12

1.84

1

3.2

Rondò-Estelle 4

Rondò B4

0.60

60° S

14

2.57

1.5

6.0

Rondò-Estelle 5

Rondò B5

8099105

SIME BLUE

MACK 2

0.75

60° S

12

3.04

1.9

2.7

Rondò-Estelle 6

1.00

60° S

14

4.23

2.8

6.0

TYPE

Nozzle

Pump

pressure

Burner

output

Combustion head

adjustment

Air damper

adjustment

GPH

Angle

bar

kg/h

±

4%

Set-point

Set-point

417T

0.40

80°

11

1.45

0.8

2.25

0.50

80°/60°

12

1.9

1.0

2.8

0.60

60°

12

2.3

2.0

3.5

0.65

60°

12

2.5

2.5

4.0

0.75

60°

13

3.0

3.5

5.0

418T

0.65

60°

14

2.7

1.8

2.9

0.75

60°

12

2.9

2.0

3.0

0.85

60°

12

3.3

2.2

3.2

1.00

60°

12

3.8

2.8

3.3

1.10

60°

12

4.2

3.8

3.5

1.25

60°

13

5.1

4.8

4.7