30

4

COMMISSIONING, USE and MAINTENANCE

INSTALLATION, SERVICING AND REPAI-

RS MUST BE CARRIED OUT BY ONLY AU-

THORISED PERSONS

COMMISSIONING INSTRUCTIONS

A Commissioning checklist is included

in this manual and must be completed

by the engineer at the time of commis-

sioning.

General

Please note: the combustion for this ap-

pliance has been checked, adjusted and

preset at the factory for operation on the

gas type defi ned on the appliance data

plate. However, it is advisable to check

for correct combustion having fi rst che-

cked the following.

• That the boiler has been installed in

accordance with these instructions

• The integrity of the fl ue system and

the fl ue seals

•

The integrity of the boiler combustion

circuit

Proceed to put the boiler into operation

as follows:

Check the operational (working)

1.

gas inlet pressure.

Set up the boiler(s) to operate at

maximum rate as described in

4.5.1(chimney sweep)

With the boiler operating in the ma-

ximum rate condition check that the

operational (working) gas pressure

at the inlet gas pressure test point

(see fi g 16 item 1) complies with the

requirements of table 1.3.

Ensure that this inlet pressure can

be obtained with all other gas ap-

pliances in the property working.

Combustion check

2.

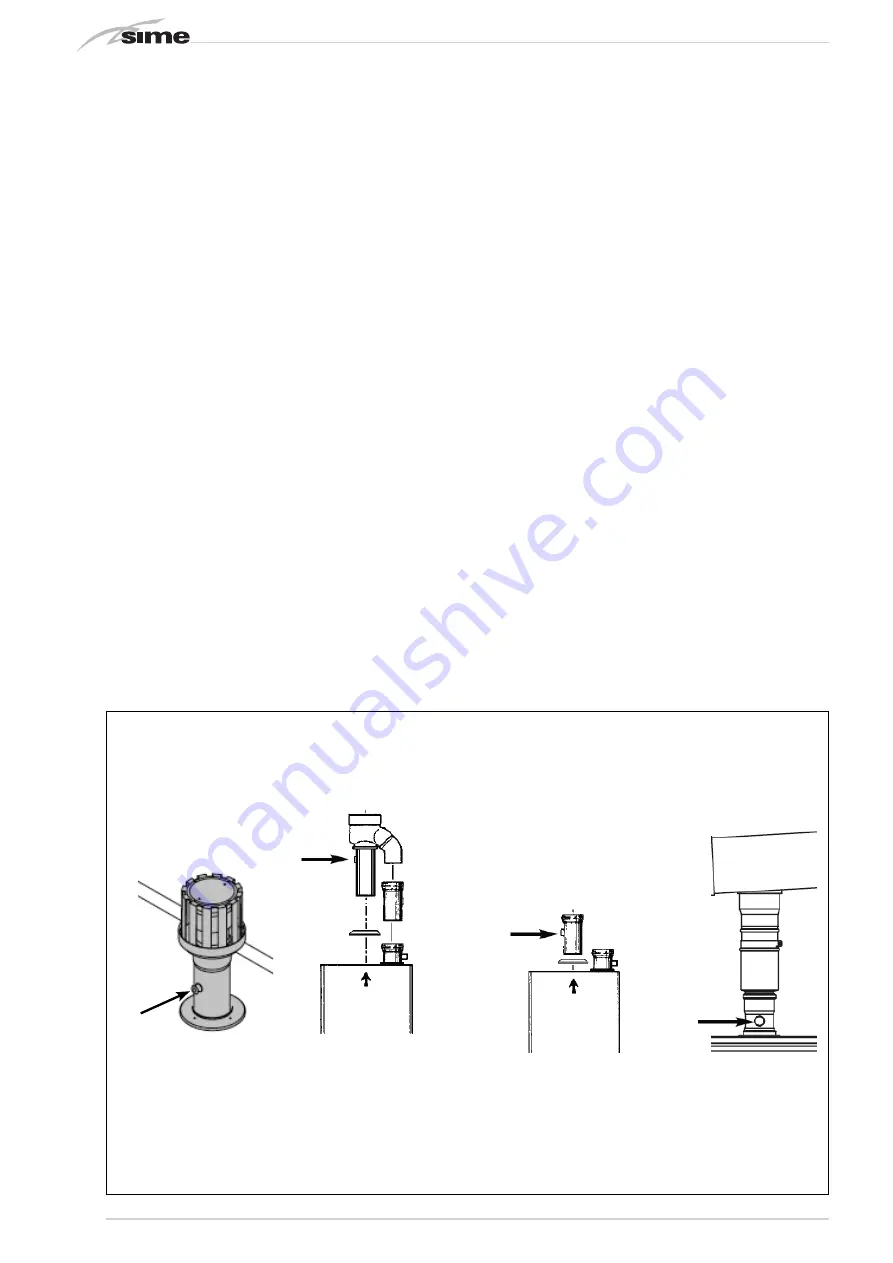

Connect the fl ue gas analyser to the

fl ue gas sampling point as shown in

the diagram.

Procedure for checking the combu-

stion.

Operate the boilers in “Chimney

Sweep “mode as described in sec-

tion 4.5.1 and record the measure-

ments from the fl ue gas analyser

on both minimum and maximum

output.

Compare the results to the fol-

lowing:

CO less than 200ppm

CO2 between 8.7% and 9.3% natural

gas, and 9.9% and 10.5% LPG

Ratio less than 0.004

If the combustion reading is grea-

ter than the acceptable value AND

the integrity of the complete fl ue

system, combustion circuit seals

have been verifi ed, AND the gas in-

let pressure has been verifi ed, AND

the boiler parameter settings are

correct, proceed as shown in 4.2.2

Any adjustments should be done in

small steps and adjustments of no

more than 1/8th of a turn should

be made, waiting at least 1 minute

between adjustments to allow the

settings to stabilise. Using the CO2

reading, adjustments should be

made to the “OFF-SET” screw (6 fi g

16) if it is incorrect at the minimum

output, or to the “SHUTTER” (5

fi g16) if it incorrect at the maximum

output.

If an acceptable setting level can-

not be achieved, re-confi rm that the

integrity of the fl ue system, combu-

stion circuit and working gas supply

pressure. If required contact HUNT

Heating for further assistance.

Fig. 15/a