Operation

9

Attaching to the Tractor

Silvan Super Series 400 litre linkage sprayers are

equipped to fit tractors with either Category 1 or 2

linkages. The 600L, 800L & 1100L fit Cat 2 only.

On the 400 litre the inner end of each lower

linkage pin is Category 1 and the outer end is

Category 2. The lower holes in the top connection

plates are Category 1 and the upper holes are

Category 2.

Remove the PTO shaft from the sprayer by

depressing the locking pin. Lower the tractor

linkage

and attach it to the sprayer’s lower hitch

pins of the appropriate category, then connect the

top link using

the tractor’s top link pin. Secure the

linkage arms and top link pin with the tractors

lynch pins. Raise the tractor linkage to the desired

spraying height and level the sprayer by adjusting

the length of the top link and by using the lower

arm levelling mechanism.

Clean and grease the splines on the tractor and

sprayer PTO stub shafts and install the PTO shaft

making sure that the spring-loaded locking pins

engage in the interference grooves of both stub

shafts. Ensure that the PTO shaft guard chains,

if fitted, are attached to the sprayer and tractor.

PTO Shaft Length (Refer to instruction

booklet INS42 attached to PTO shaft)

Note: Upon delivery of a new PTO driven sprayer,

it is the selling dealer’s responsibility to install and

set the PTO driveshaft to the correct length, as

part of the installation service. The following

information is provided for reference.

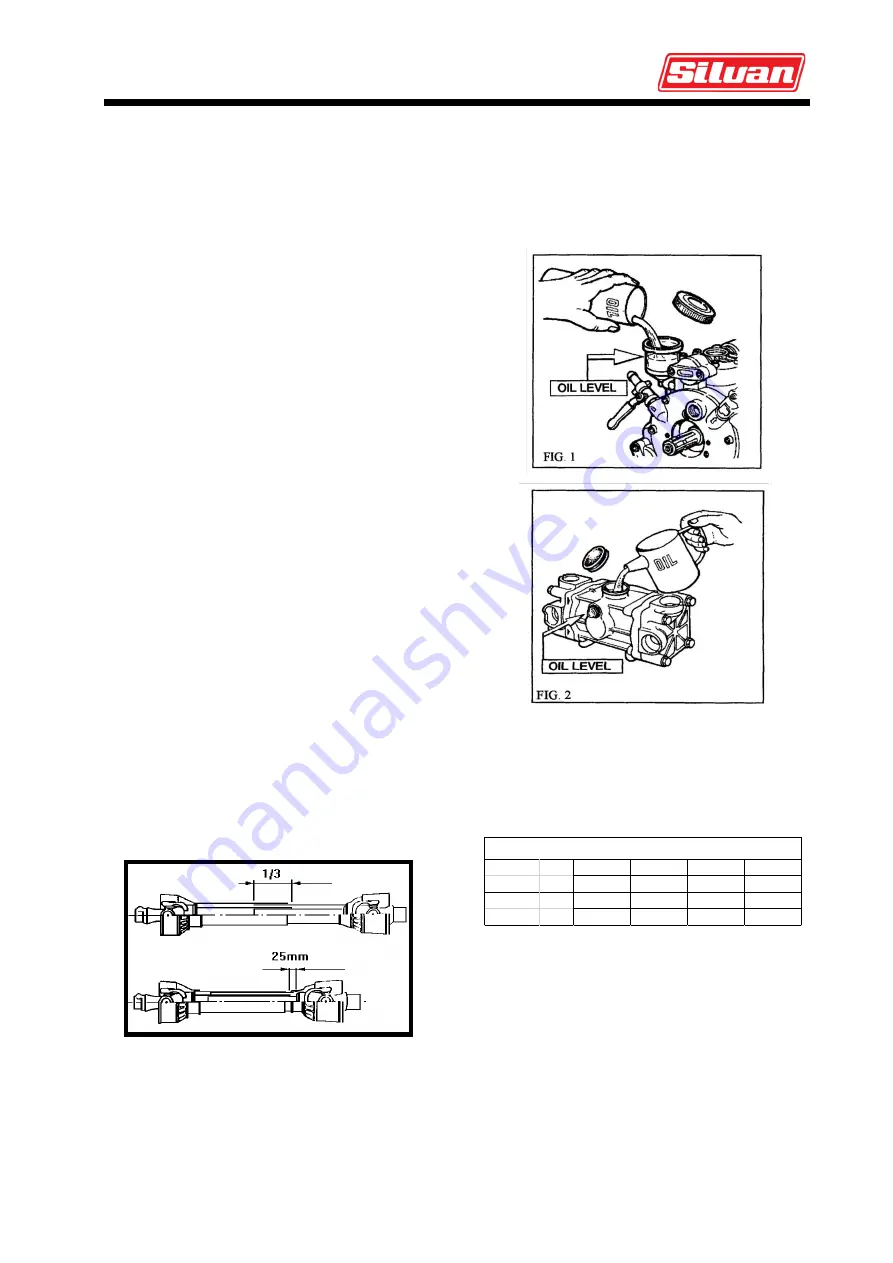

Set the linkage height so that the ends of the two

shafts are at their closest distance. Install the

PTO shaft making sure that there is at least

25mm of telescopic travel remaining between the

male and female sections. Raise and lower the

sprayer to check that the telescopic tubes of the

PTO overlap by approximately 1/3rd of their

length, and not less than 150mm, in all operating

positions.

Min 150mm

Min 150mm

If the PTO shaft must be shortened, cut equal

amounts from both male and female shafts and

safety covers. Carefully remove all burrs then

clean and lubricate before reassembling.

Pump

1. Check the oil level while the pump is standing

still and sitting horizontally. The oil must reach the

level indicated on the sight glass (BP75/20,

BP125/20 fig 1) or be visible on the oil level plug

(BP60/20 fig 2). Top up with SAE20W/40 oil if

necessary.

2. Adjust the air pressure in the pressure

accumulator if fitted in accordance with the

operating pressure used to spray. Adjust

according to Table A. The pressure can be

measured using a reliable bicycle fork pressure

gauge.(Note a car tyre or bicycle tyre gauge lets

too much air escape to be accurate).

Alternatively add air to the accumulator, to just

above the required pressure (using a car tyre

inflator is OK) start the pump and adjust the

pressure regulator to the required pressure then

bleed air from the accumulator until the

pulsations of the pump are least noticable, at

this point the needle on the pressure gauge will

be at its steadiest.

Spraying Bar

2-5

5-10

10-20

20-50

pressure p.s.i.

29-73

73-145

145-290 290-725

Surge air Bar

2

2-5

5-7

7

pressure p.s.i.

29

29-73

73-102

102

TABLE A