Calibration

15

Spray Pattern and Nozzle Uniformity

The overlap pattern of the boom, the spray

pattern of individual nozzles and the uniformity of

nozzle output can be tested in the following

manner. Always keep one new nozzle aside from

each set to use as comparator for this test.

1. Install the comparator nozzle, fill the sprayer

tank with clean water and operate the boom at

spraying pressure whilst stationary.

2. Examine the spray pattern from each nozzle

against a dark background. Replace any that

show streaks or signs of blockage.

3. Compare individual nozzle outputs by placing

a container of equal size, such as the Silvan

calibrated measuring jug, under each nozzle

and run the sprayer for one minute. The water

level in each container should be the same.

Replace any nozzle giving more than 10%

greater output than the comparator. Once

several nozzles are worn to this extent it is

good practice to replace the entire set.

4. Set the boom at the appropriate height for the

nozzle angle, i.e. 60 cm for 80

0

and 40 cm for

110

0

. Run the sprayer and check that the

patterns from adjacent nozzles just meet as

shown in the diagram on the previous page.

5. Remove and store the comparator nozzle.

Verifying the Calibration

After making the above tests to ensure pattern

and output uniformity are correct, repeat the

procedure at 3.0 Bar to compare the actual

nozzle output with that shown on the nozzle

selection charts. This may be done either as a

test on an individual nozzle or the full boom.

a) Nozzle Test

Measure the fluid in litres, collected from one

nozzle during one minute. The amount should

agree with the flow rate shown in the Nozzle

Selection Chart on the following pages, for the

particular type and size fitted.

If the volume collected is too low the operating

pressure may be increased and the test repeated,

alternatively if the volume is too high the pressure

can be lowered.

b) Boom Test

1. Partly fill the sprayer tank with water and mark

the level or refer to the sight gauge.

2. Run the sprayer at 3.0 Bar for several minutes

with all boom sections operating and measure

the time carefully.

3. Refill the sprayer tank to the mark using a

measuring jug and record the amount added.

4. The average output for one nozzle in l/min can

be calculated as follows. It should agree with

the flow rate shown at 3.0 Bar in the nozzle

selection chart, for the particular type and size

fitted.

5. If the nozzle output is lower than shown in the

chart the pressure may be increased and the

test repeated or, if more than shown, the

pressure may be reduced.

Nozzle Care and Maintenance

Nozzles are one of the most critical components

in the spraying system and yet are often the most

neglected. Worn or damaged nozzles result in

over application of expensive chemicals, crop

damage and environmental contamination.

They should be examined and checked regularly

by the method shown above. Replace nozzles

which are not within 10% of the datum.

Always keep a quantity of spare nozzles with the

sprayer for immediate replacement in the field

when necessary.

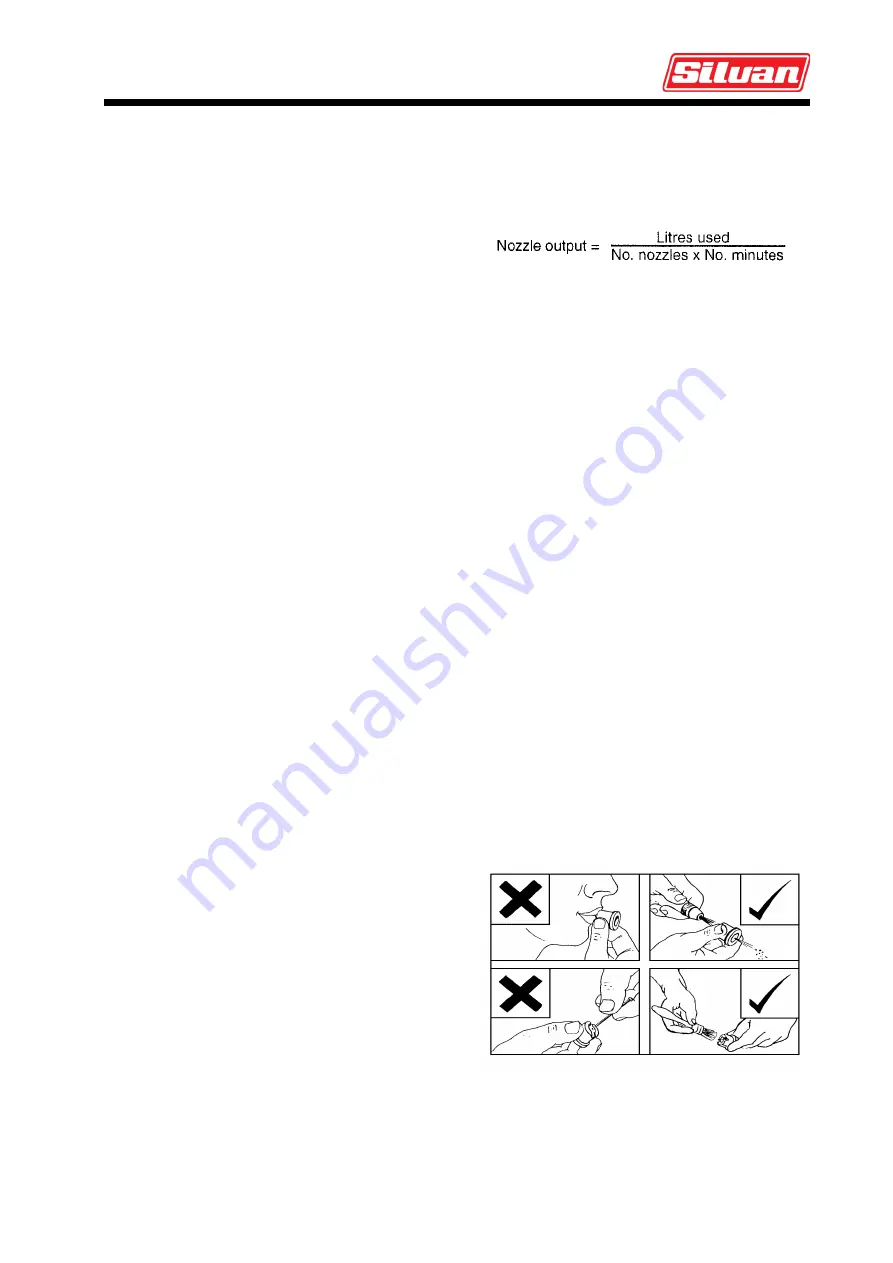

Never attempt to clear a nozzle by blowing

through by mouth and never remove stubborn

deposits with a pin, wire or sharp instrument.

Blocked nozzles should be soaked in clean, warm

water with a mild detergent added and carefully

cleaned only with a soft brush or airline.

A new nozzle should be kept as a testing

comparator and it is recommended that all

nozzles are renewed once a year or at the first

signs of deterioration, whichever occurs first.