Reporting

151137

9-3

SBUS Class A supervision restore

Trouble

3

333

Exp ID

000

Printer is out of paper.

Trouble

1

335

Exp ID

000

Printer paper restored.

Trouble

3

335

Exp ID

000

Printer offline.

Trouble

1

336

Exp ID

000

Printer back online.

Trouble

3

336

Exp ID

000

Auto Dialer Test Communication Trouble

Trouble

1

350

0

Line #

Auto Dialer Test Communication Trouble Restore

Trouble

3

350

0

Line #

Phone line 1 trouble detected

Trouble

1

351

00

000

Phone line 1 trouble restore

Trouble

3

351

00

000

Phone line 2 trouble detected

Trouble

1

352

00

000

Phone line 2 trouble restore

Trouble

3

352

00

000

Unable to report to an account

Trouble

1

354

Acct #

Acct #

Report to an account successful

Trouble

3

354

Acct #

Acct #

Water flow switch trouble

Trouble

1

373

00

Zone

Manual pull switch trouble

Trouble

1

373

00

Zone

Detector trouble

Trouble

1

373

00

Zone

Zone-based Aux 1 switch trouble

Trouble

1

373

01

Zone

Zone-based Aux 2 switch trouble

Trouble

1

373

02

Zone

Supervisory switch trouble

Trouble

1

373

00

Zone

Water flow switch trouble restore

Trouble

3

373

00

Zone

Manual pull switch trouble restore

Trouble

3

373

00

Zone

Detector trouble restore

Trouble

3

373

00

Zone

Zone based, AUX 1 switch trouble restore

Trouble

3

373

01

Zone

Zone based, AUX 2 switch trouble restore

Trouble

3

373

02

Zone

Supervisory switch trouble restore

Trouble

3

373

00

Zone

System-based AUX1 switch trouble

Trouble

1

373

01

000

System based AUX 2 switch trouble

Trouble

1

373

02

000

External Reset/Silence/Fire Drill switch trouble

Trouble

1

373

00

000

System-based AUX1 switch trouble restore

Trouble

3

373

01

000

System-based AUX2 switch trouble restore

Trouble

3

373

02

000

External Reset/Silence Fire Drill trouble restore

Trouble

3

373

00

000

Positive Alarm Sequence acknowledge switch

trouble

Trouble

1

373

00

Zone

Positive Alarm Sequence acknowledge switch

trouble restore

Trouble

3

373

00

Zone

An unexpected SLC device has been detected.

Trouble

1

380

Exp ID

Pnt #

An unexpected SLC device has been removed.

Trouble

3

380

Exp ID

Pnt #

User initiated a system reset

Restore/Reset

1

401

00

000

Remote programming ended normally.

Trouble

1

412

00

000

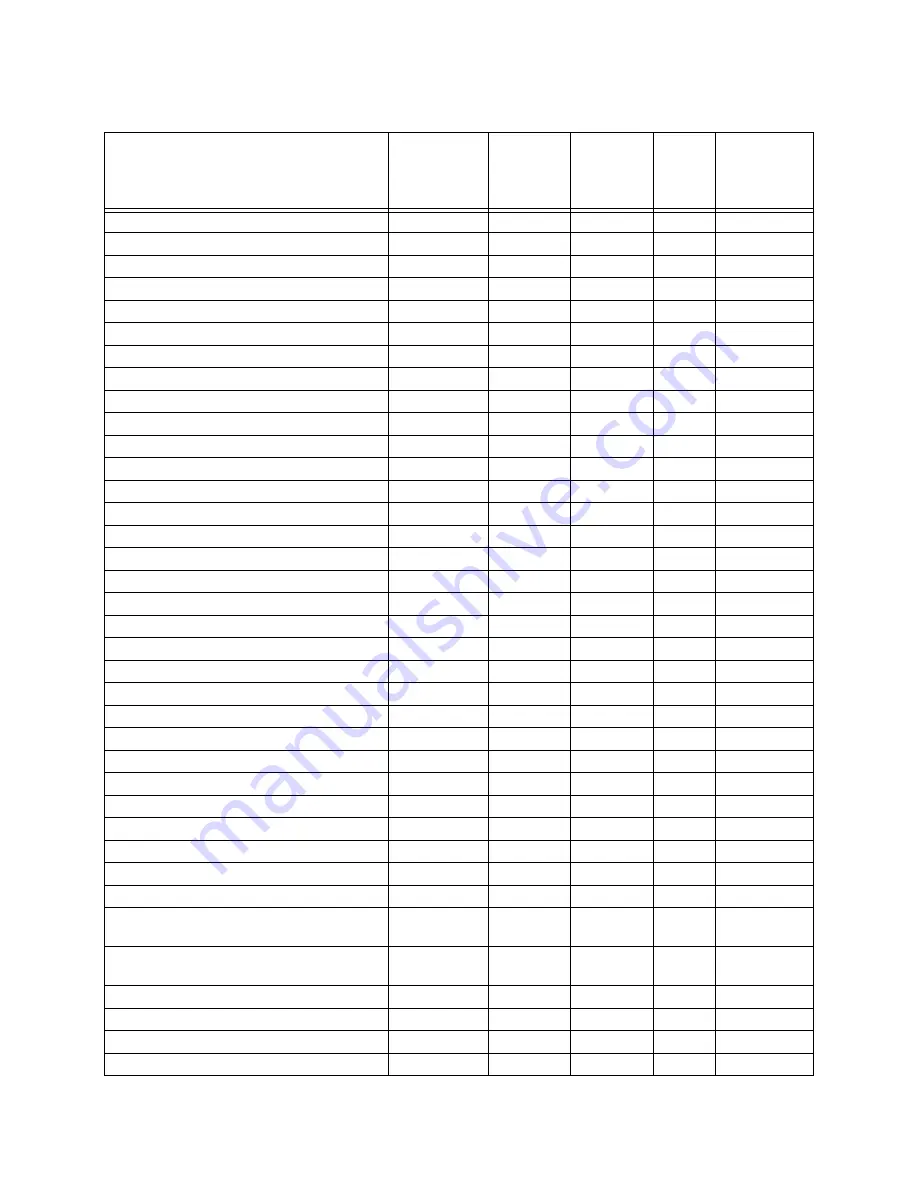

Table 9-2: Ademco Contact ID Output

Event Description

Event Family

Event

Qualifier

1=New,

3= Restore

Event Code Group #

Zone /

Contact ID #

Summary of Contents for INTELLIKNIGHT 5820XL

Page 16: ...IntelliKnight 5820XL Installation Manual 3 4 151137 Figure 3 1 Wire Routing Example ...

Page 24: ...IntelliKnight 5820XL Installation Manual 3 12 151137 ...

Page 68: ...IntelliKnight 5820XL Installation Manual 4 44 151137 ...

Page 82: ...IntelliKnight 5820XL Installation Manual 5 14 151137 ...

Page 104: ...IntelliKnight 5820XL Installation Manual 6 22 151137 ...

Page 148: ...IntelliKnight 5820XL Installation Manual 7 44 151137 ...

Page 162: ...IntelliKnight 5820XL Installation Manual 8 14 151137 ...

Page 172: ...IntelliKnight 5820XL Installation Manual 9 10 151137 ...

Page 178: ...IntelliKnight 5820XL Installation Manual 10 6 151137 ...