11

CUTTER ADJUSTMENTS

When the strap cutter begins to wear or

strapping seems difficult to cut off the strap

cutter may need adjustment. Contact the

Signode tool repair center or your Signode

representative for information on accessing

the adjustment screw.

Before attempting to adjust the cutter, first

place a single layer of strapping in the tool

and pull the weld handle to the full back

position.

Adjust the cutter blade position by turning

the adjustment screw inward (clockwise) or

out (counter-clockwise) using 1/8 turn

increments. Adjust the cutter blade so that

the cutting edge of the blade places a slight

impression into the single layer of strap.

Remove the

single layer of

strap. Run one

or more tool

cycles and

continue to

adjust the

cutter as

necessary until

proper strap

cut-off has

been obtained.

NOTE: Do not over tighten cutter mechanism

as lower strap damage or poor strap cut-off

will occur.

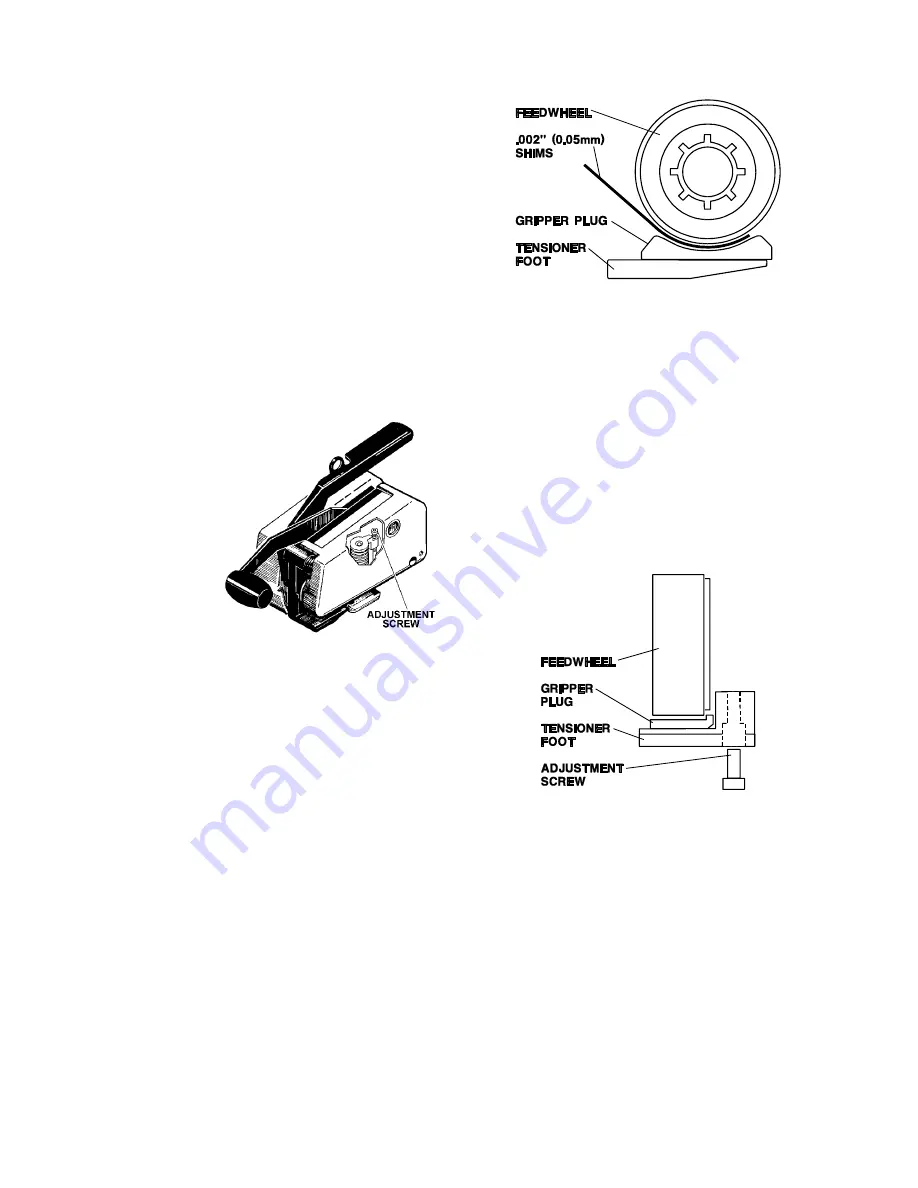

FEEDWHEEL TO GRIPPER PLUG

The feedwheel to gripper plug clearance may

require readjustment if the feedwheel,

tensioner foot or gripper plug has been

replaced. The feedwheel clearance should

also be inspected during routine tool

maintenance procedures. Adjust the

feedwheel clearance as follows:

1. Open the tensioner foot and place 1 to 2

layers of .002", 1/2" wide (.05 x 12mm)

shim stock between the feedwheel and

the gripper plug.

NOTE: Using a single .004" (.10mm) shim is

not recommended because a single thicker

shim may not conform to the feedwheel

shape, resulting in inaccurate clearance

measurements.

2. Release the tensioner foot to pinch the

shims between the feedwheel and the

gripper plug. Holding the shims with one

hand, jog the air motor on and off to

rotate the feedwheel at least one full

revolution. If properly adjusted the tool

should lightly tug at the shims while

rotating. Clearance between the

feedwheel and gripper plug at this point

should fall between .002"-.004" (.05-

.10mm).

3. If the feedwheel needs to be adjusted,

use a 3/32" hex wrench to rotate the

adjustment screw located in the

tensioner foot.

Turn the adjustment screw clockwise for

greater clearance and counter-clockwise

for less clearance. Turn the adjustment

screw only in 1/8 turn increments. After

each 1/8 turn, repeat the adjustment

testing as described in step 2.

4. Once the proper clearance has been

found the tool can be returned to service.

NOTE: Never turn out the adjustment screw

more than 1/8 turn at a time without testing

or completely removing the adjustment

screw. These actions will severely damage

both the feedwheel and gripper plug.

Summary of Contents for TENSION-WELD VXL-2000-Z

Page 1: ...VXL 2000 Z and VXM 2000 Z TENSION WELD STRAPPING TOOLS...

Page 29: ...29...

Page 38: ...38...