2. Part of activities independent of serial number

5 - 3

Siemens AG

SPR2-230.814.01

Page 3 of 8

SIREMOBIL Iso-C 3D

Medical Solutions

Rev. 05

08.04

CS PS 24

•

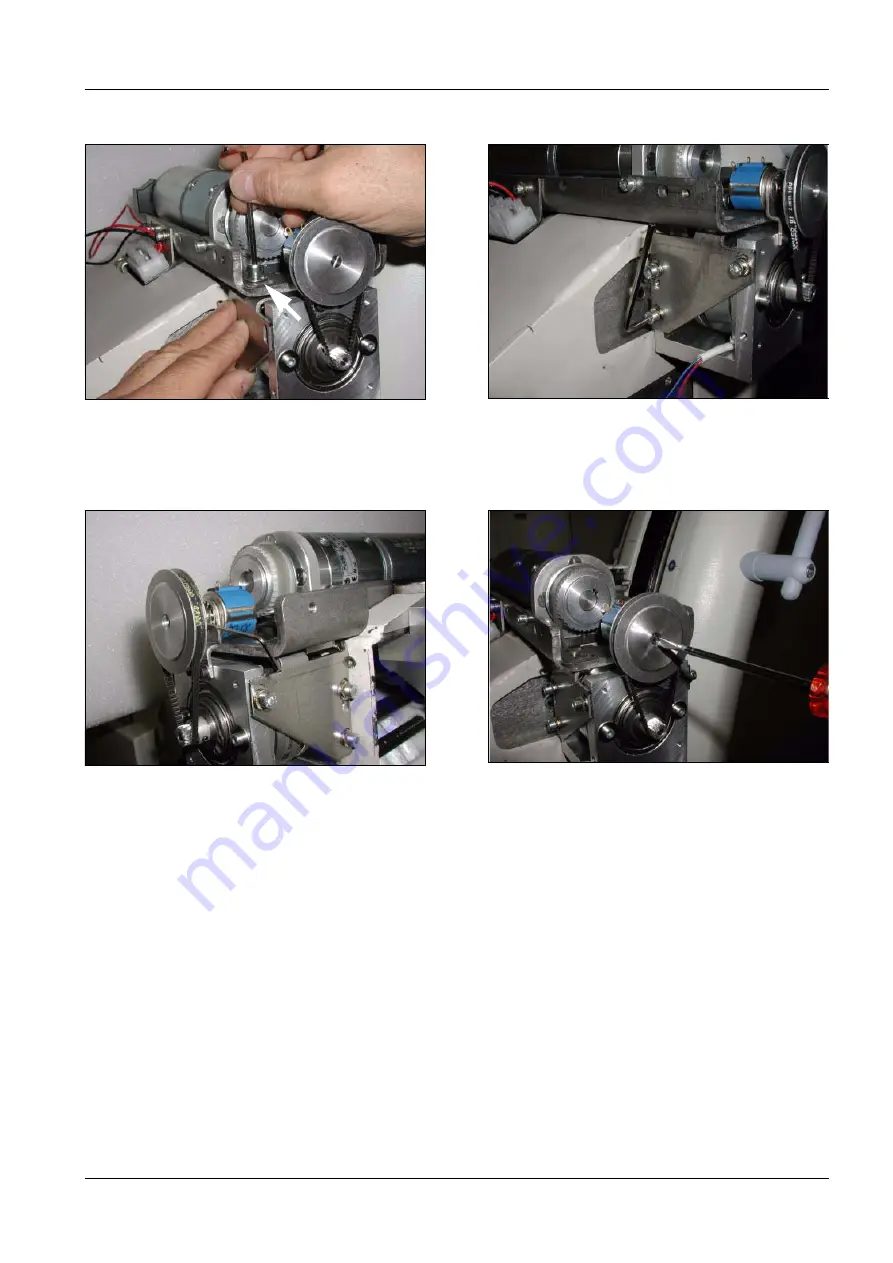

Attach lateral brackets (Fig. 8) on both sides (Fig. 9), first on top and then on the side.

•

Move the C-arm into the -95° degree orbital position (limit switch = side of image

intensifier).

•

Loosen the Allen screw at the belt pulley (Fig. 10).

•

Attach the outside toothed belt (see Fig. 10).

•

Turn the potentiometer counterclockwise into the end position using a screwdriver

(Fig. 11).

•

Once the potentiometer is in this position, turn it fully clockwise twice.

•

Secure the belt pulley with the Allen screw (Fig. 10).

Fig. 8

Lateral bracket

Fig. 9

Lateral bracket

Fig. 10 Belt pulley

Fig. 11 Potentiometer

top