3-24

S7-200 Programmable Controller, CPU 210

C79000-G7076-C235-01

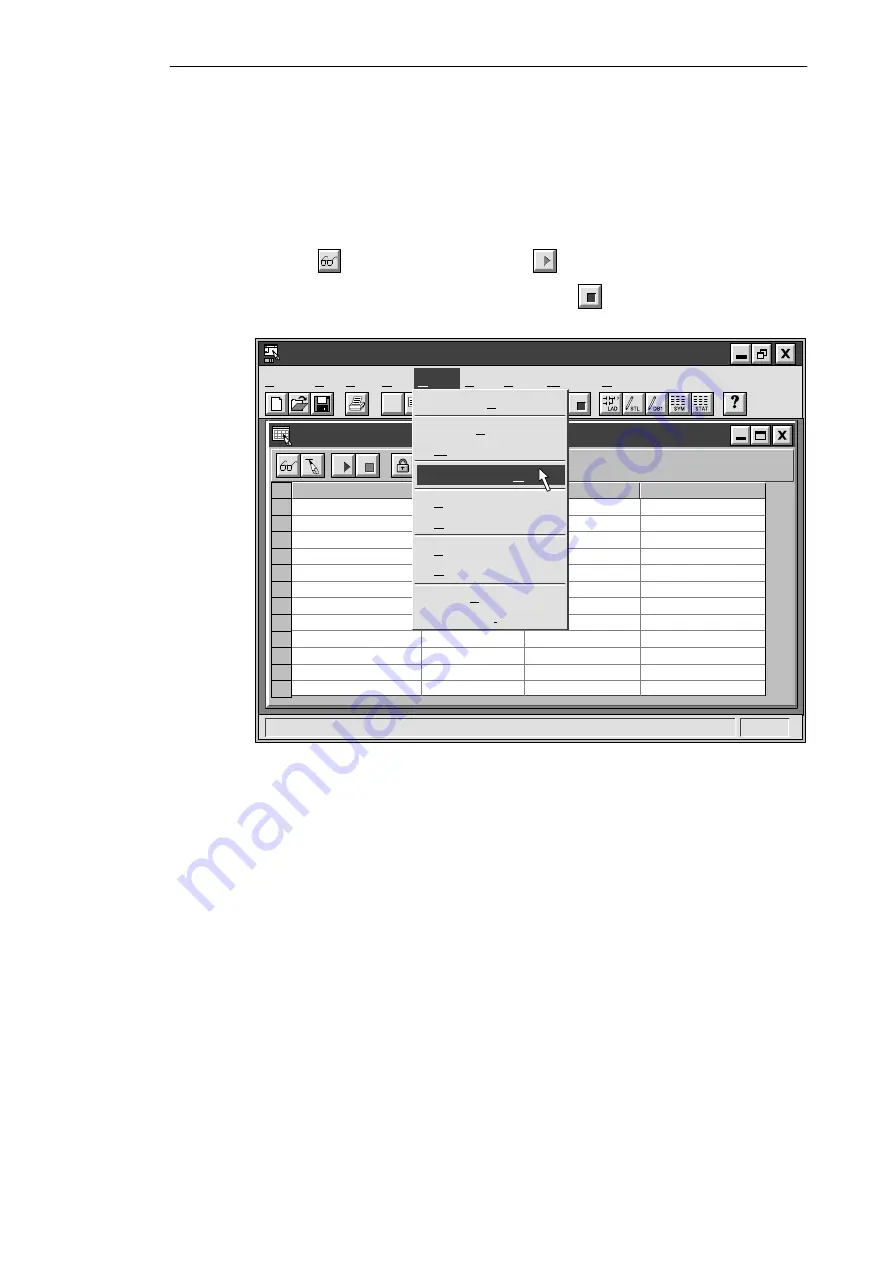

Using the Status Chart to Monitor and Modify the Current Values of the Program

You can use the Status Chart to monitor or modify the current values of any I/O points or

memory locations. Reopen the Status Chart window, if necessary, and select the menu

command Debug

"

Chart Status On, as shown in Figure 3-23. As you switch inputs on or

off with the CPU in RUN mode, the Status Chart shows the current status of each element.

S

To view the current value of the elements in your program, click the Single Read

button

or the Continuous Read button

in the Status Chart window.

S

To stop the reading of status, click the Stop button

in the Status Chart window.

✂

Project Edit View CPU Debug Tools Setup Window Help

STEP 7-Micro/WIN - c:\microwin\house.prj

Status Chart

Address

Format

Change Value To

Current PLC Value

Bit

Bit

Bit

Bit

Bit

“Zone_1”

Bit

Bit

Bit

2#0

2#0

2#0

2#0

“Zone_2”

“Armed”

“Panic_Alarm”

“LED”

“Alarm”

“Low_Alert”

“Modem”

2#0

2#0

2#0

2#0

Debug

Execute Scans...

Single Read

Write

Chart Status On

Force Value

Unforce Value

Force Value

Unforce Value

Read All Forced

Unforce All

“Alert_Timer”

“Exit_Timer”

Figure 3-23 Monitoring the Status Chart of the Sample Program

Getting Started with a Sample Program

Summary of Contents for Simatic S7-200 CPU 210

Page 10: ...x S7 200 Programmable Controller CPU 210 C79000 G7076 C235 01 Contents ...

Page 116: ...A 16 S7 200 Programmable Controller CPU 210 C79000 G7076 C235 01 CPU 210 Data Sheets ...

Page 126: ...F 2 S7 200 Programmable Controller CPU 210 C79000 G7076 C235 01 CPU 210 Order Numbers ...

Page 138: ...Index 12 S7 200 Programmable Controller CPU 210 C79000 G7076 C235 01 Index ...