2 Installation

International English

MICROMASTER 440 Operating instructions

26

6SE6400-5CA00-0BP0

Operation with long cables

Caution

The control, power supply and motor leads

must

be laid separately. Do not feed

them through the same cable conduit/trunking. Never use high voltage insulation

test equipment on cables connected to the inverter.

All inverters will operate at full specification with cable lengths up to 50 m screened

or 100 m unscreened.

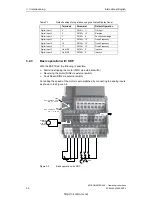

2.4.2

Power and motor connections

Warning

♦

Isolate the mains electrical supply before making or changing connections to

the unit.

♦

Ensure that the inverter is configured for the correct supply voltage: single /

three-phase 230 V MICROMASTERS must not be connected to a higher

voltage supply.

♦

When synchronous motors are connected or when coupling several motors in

parallel, the inverter must be operated with voltage/frequency control

characteristic (P1300 = 0, 2 or 3).

Caution

After connecting the power and motor cables to the proper terminals, make sure

that the covers have been replaced properly before supplying power to the unit!

Note

♦

Ensure that the appropriate circuit-breakers/fuses with the specified current

rating are connected between the power supply and inverter

(see Tables

starting on page 77

).

♦

Use Class 1 60/75

o

C copper wire only (for UL compliance). For tightening

torque see table

on page 79

.

♦

To tighten up the power terminal screws use a 4 - 5 mm cross-tip screwdriver.

Access to the power and motor terminals

The procedure for accessing the power and motor terminals on the

MICROMASTER 440 Inverter is illustrated in Appendices. Please also refer to the

photographs showing the Power Terminal connections and the Control Terminal

connections on the inside of the back cover of this manual.

When the covers have been removed to reveal the terminals, connect the power

and motor connections as shown on the next page.

http://nicontrols.com