13/61

Building Technologies

Basic Documentation LMO39…

CC1P7154en

3 Basic unit

15.03.2018

3 Basic unit

∂

The housing is made of impact-proof, heat-resistant and flame-retarding plastic. It

is of plug-in design and engages audibly in the base

∂

Burner controls LMO39... and plug-in base AGK11.6 are silver-grey (RAL7001)

∂

The housing accommodates the

–

microcontroller for the program control and the control relays for load control

–

electronic flame signal amplifier

– lockout reset button with its integrated 3-color signal lamp for operational status

and fault status messages and the socket for connecting the interface OCI400...

adapter or the AGK20... lockout reset button extension

∂

All safety-related digital inputs and outputs of the system are monitored by means

of a contact feedback network

∂

The display and operating unit AZL2… is designed for direct connection to the

LMO39…

∂

The LMO39... is operated and parameterized via the AZL2... or with the help of the

OCI410 / ACS410

∂

Burner capacity unlimited (thermal output on startup

′

120 kW)

∂

3 repetitions in the event of loss of flame during operation (can be parameterized)

Default setting: Non-alterable lockout

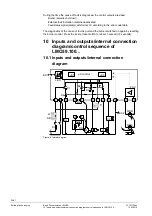

Figure 5: Example: 1-/2-stage oil burner

The diagram shows the full scope of functions of the LMO39… system. The actual

functions are to be determined based on the respective execution/configuration.

3.1 Time parameters

:

Parameterized times see

Type summary

.

Both the prepurge time and the safety times are safety-related and can be changed by

the OEM with the help of the display and operating unit AZL2... or PC software

ACS410.

LMO39…