Procedure

1.

Push the tube into the tube screw fitting to the stop.

2.

During initial fitting: Hold the fitting bolt steady and tighten the cap nut with 1 1/4

revolutions.

3.

During further fittings: Tighten the cap nut to the previous position (the resistance

increases noticeably) and then tighten slightly.

5.4.4

Using a push-in fitting (pneumatic)

Overview

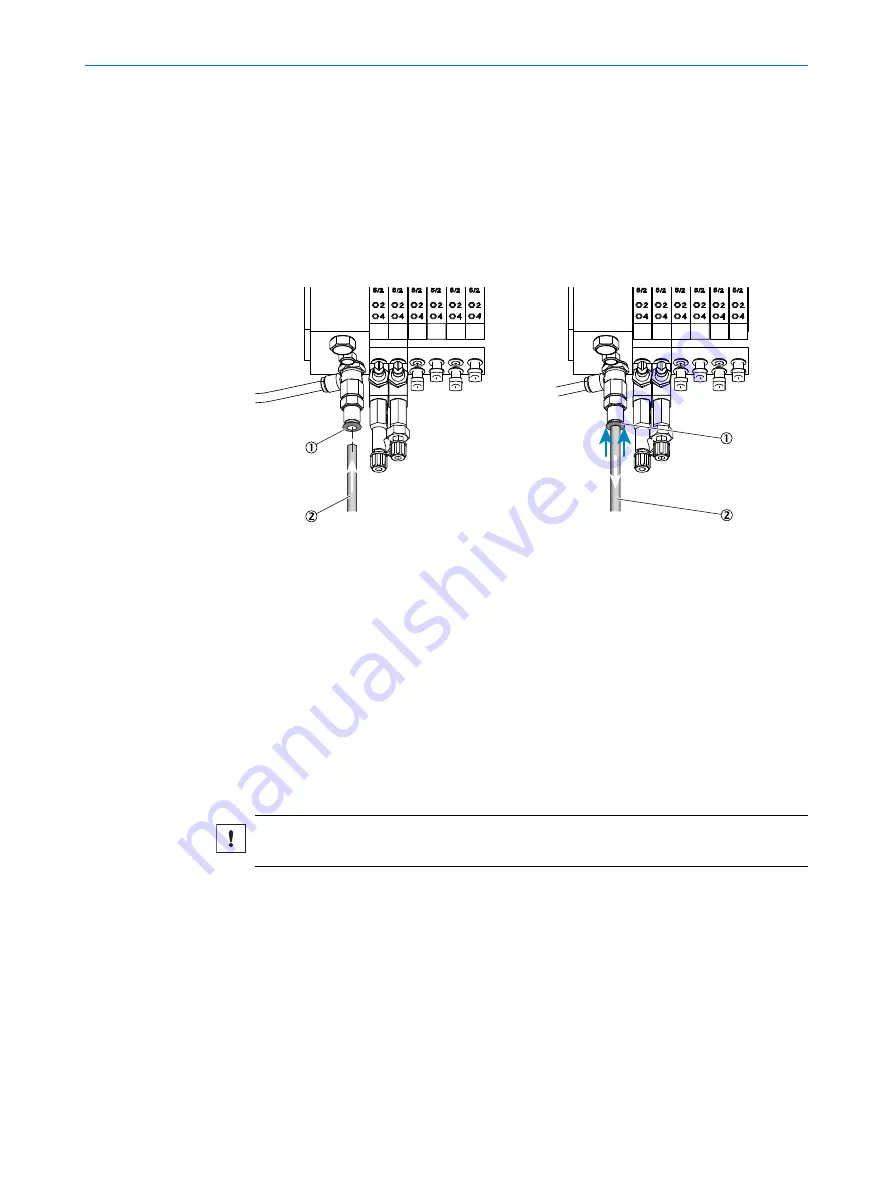

Figure 9: Push-in fitting with retaining ring (example shown)

1

Retaining ring

2

Tube

Procedure

Fitting the tube

1.

Push the tube in.

Removing the tube

1.

Press the retaining ring in.

2.

Pull the tube out.

5.4.5

Laying the hose bundle line

Important information

NOTICE

Protect the line from damage (chafing through vibration, mechanical load).

Procedure

1.

Lay the hose bundle line from the gas sampling unit to the measuring device.

°

An additional length of 0.5 m is required at the gas sampling unit for the

internal lines.

°

An additional length of 3.5 m is required from the installation plate for the

internal lines.

2.

Observe a minimum bending radius of 300 mm.

5

MOUNTING

26

O P E R A T I N G I N S T R U C T I O N S | MCS200HW

8021889/1D1T/V3-1/2021-09 | SICK

Subject to change without notice