5

Electrical installation

5.1

Important notes

Information on the requirements that must be met for safe integration of the localiza‐

tion controller and 2D LiDAR sensors into the control and electronics of the machine,

see the corresponding operating instructions.

DANGER

Hazard due to electrical voltage

Hazard due to unexpected starting of the machine

b

Make sure that the machine is (and remains) disconnected from the power supply

during the electrical installation.

b

Make sure that the dangerous state of the machine is (and remains) switched off.

b

Carry out the electrical installation work in conformity with EN 60204-1.

b

Use suitable power supply.

b

Check that all earthing points are connected with the same ground potential.

b

Connect the shielding of all data lines (Ethernet, CAN, serial) directly to the func‐

tional earth (FE) at the control cabinet entry point.

5.2

MicroScan3

The electrical installation is described in detail in the operating instructions:

•

8021911

The examples are given for microScan3 EFI-pro variant but are also applicable for Ether‐

Net/IP™ and PROFINET.

5.2.1

Electrical setup

Supply voltage and power consumption

Supply voltage:

•

24 V DC (16.8 … 30 V DC) (SELV/PELV) according to IEC 60364441

•

Must be able to bridge a brief power outage of 20 ms with a starting voltage of

≤ 3 A

The microScan3 consumes the following:

•

Power consumption ≤ 11 W (typ. 7.2 W)

•

Power consumption Standby typical 7 W

System plug and connections

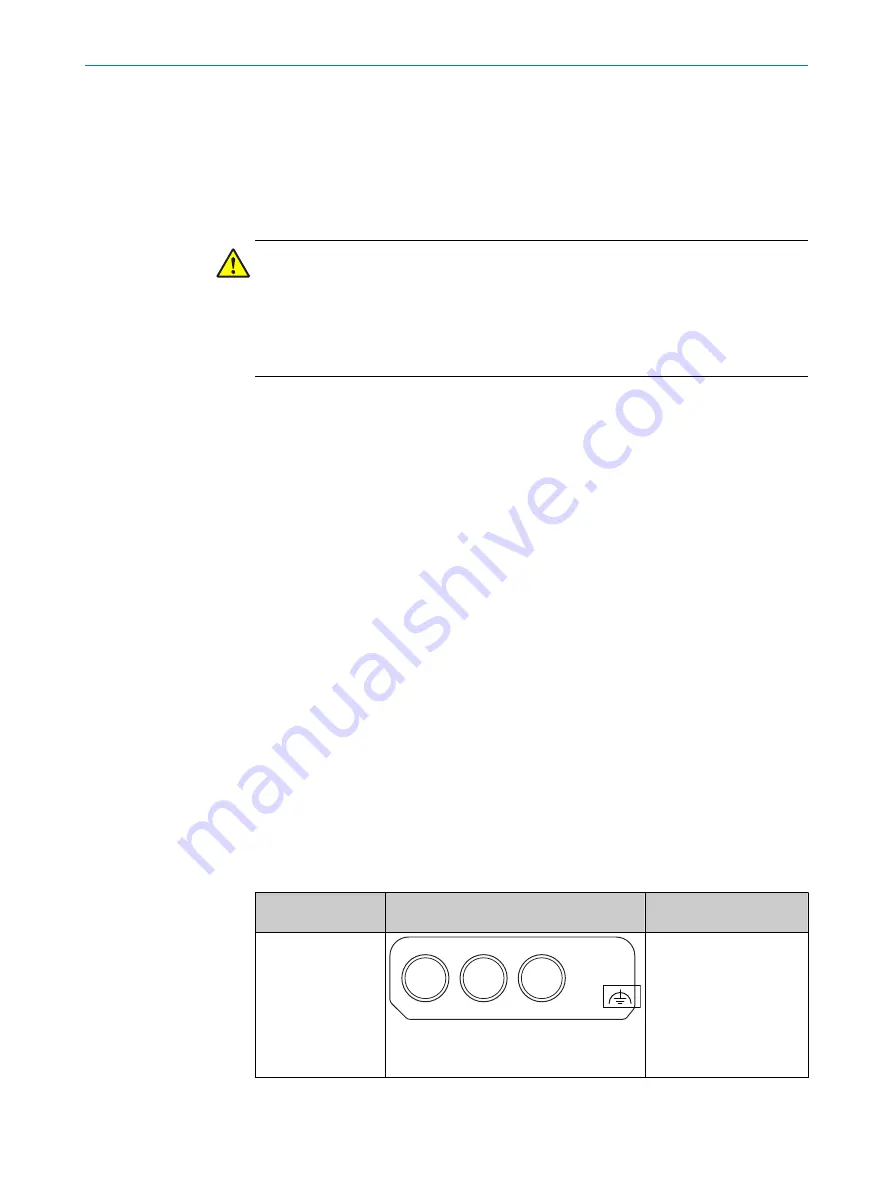

Table 2: Position of the electrical connections

Safety laser scan‐

ners

Suitable system plug

Plug connector

microScan3 – Ether‐

Net/IP™

XD1

XF1

XF2

MICSX-BANNZZZZ1 (part number:

2086102)

•

XD1: voltage supply,

•

XF1, XF2: 2 × Ethernet

for EtherNet/IP –

CIP Safety, data output,

configuration, and diag‐

nostics.

5

ELECTRICAL INSTALLATION

10

T E C H N I C A L I N F O R M A T I O N | LiDAR Localization Hardware Integration

8024819/2019-09-02 | SICK

Subject to change without notice