b

Read the operating instructions before using the Inspector.

b

Connection, assembly, and settings must be performed

by competent technicians.

b

Do not connect external I/O signals to the Inspector while

it is powered. This may damage the device.

b

Make sure that any loose cable ends are properly separated

or isolated before powering the Inspector. Otherwise the

device may be damaged.

b

Protect the Inspector from moisture and dirt during

operation.

b

Do not use the Inspector in areas with risk for explosion.

b

To keep IP 67 classification, open and close the front

window only with the supplied tool. Make sure that the seal

fits properly (Flex)

b

To avoid damages, only Inspector accessory lenses offered

by SICK are allowed to be used (Flex)

b

Minimize the risk of getting dust into the device by changing

the lenses in a dust-free environment. Do not keep the

device without the front window and wipe off the front

window before you open it (Flex)

2D vision

8013387/YUV5 ∙ Printed in Germany (2016-06)

All rights reserved. Subject to change without prior notice.

Q U I C K S TA R T

Inspector I10, I20, I40

Australia

Phone +61 3 9457 0600

1800 334 802 – tollfree

Austria

Phone +43 22 36 62 28 8-0

Belgium/Luxembourg

Phone +32 2 466 55 66

Brazil

Phone +55 11 3215-4900

Canada

Phone +1 905 771 14 44

Czech Republic

Phone +420 2 57 91 18 50

Chile

Phone +56 2 2274 7430

China

Phone +86 20 2882 3600

Denmark

Phone +45 45 82 64 00

Finland

Phone +358-9-2515 800

France

Phone +33 1 64 62 35 00

Germany

Phone +49 211 5301-301

Hong Kong

Phone +852 2153 6300

Hungary

Phone +36 1 371 2680

India

Phone +91 22 4033 8333

Israel

Phone +972 4 6881000

Italy

Phone +39 02 274341

Japan

Phone +81 3 5309 2112

Malaysia

Phone +6 03 8080 7425

Mexico

Phone +52 472 748 9451

Netherlands

Phone +31 30 2044 000

New Zealand

Phone +64 9 415 0459

0800 222 278 – tollfree

Norway

Phone +47 67 81 50 00

Poland

Phone +48 22 539 41 00

Romania

Phone +40 356 171 120

Russia

Phone +7 495 775 05 30

Singapore

Phone +65 6744 3732

Slovakia

Phone +421 482 901201

Slovenia

Phone +386 591 788 49

South Africa

Phone +27 11 472 3733

South Korea

Phone +82 2 786 6321

Spain

Phone +34 93 480 31 00

Sweden

Phone +46 10 110 10 00

Switzerland

Phone +41 41 619 29 39

Taiwan

Phone +886 2 2375-6288

Thailand

Phone +66 2645 0009

Turkey

Phone +90 216 528 50 00

United Arab Emirates

Phone +971 4 88 65 878

United Kingdom

Phone +44 1727 831121

USA

Phone +1 800 325 7425

Vietnam

Phone +84 945452999

Detailed addresses and additional

representatives and agencies

at

www.sick.com

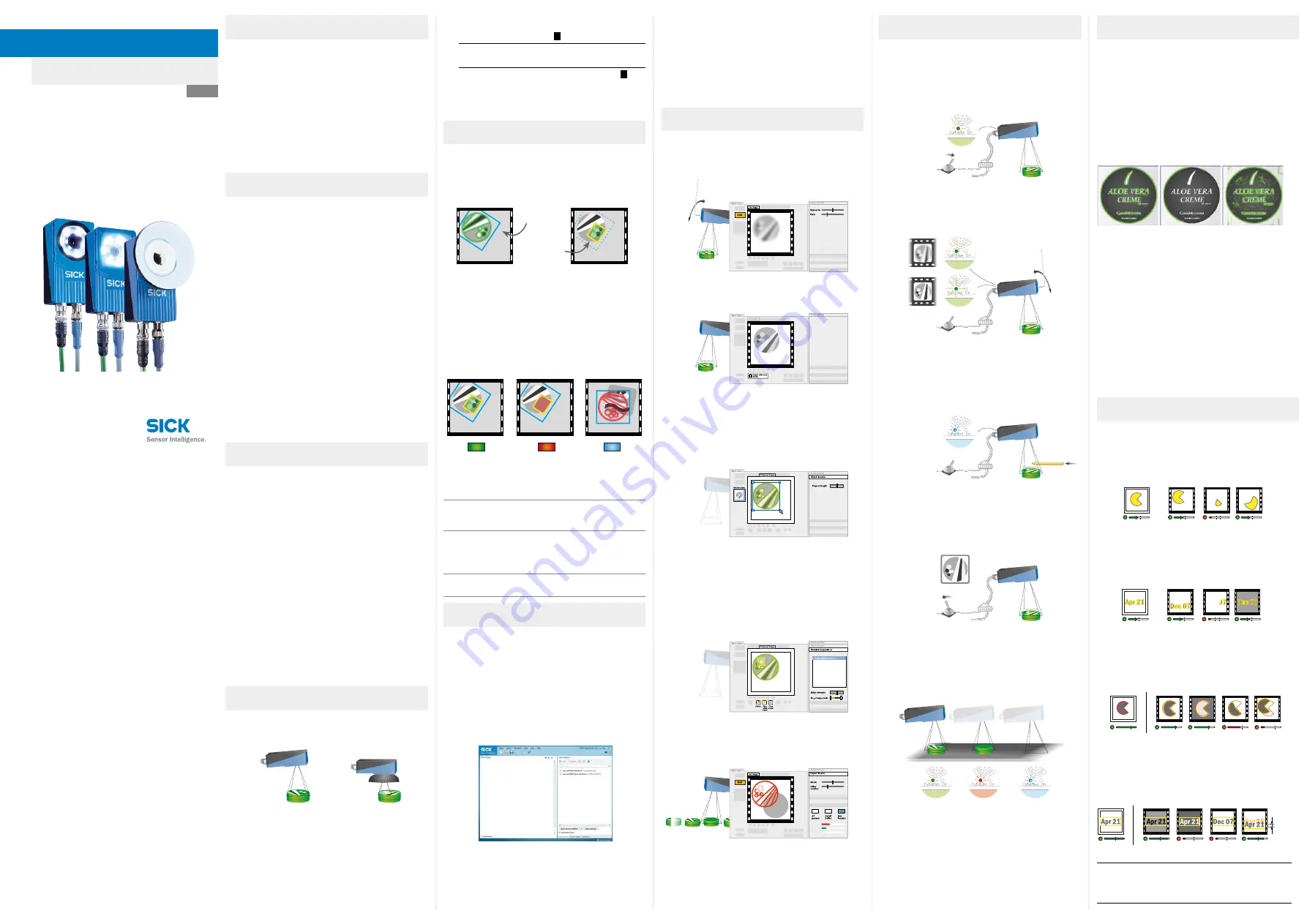

Installing

Safety

Product Features

Teaching with SOPAS ET

Teaching without PC

Object Locator

Detailed Inspections

Overview

SOPAS ET

Pixel counter

Counts the number of pixels within the region that has an

intensity (grey scale value) that is within a specified range.

The location of these pixels is not considered, only the

number of pixels.

Edge pixel counter

Similar to the Pixel counter, but counts the number of

edge pixels in the region. The location of the edges is not

considered, only the number of pixels.

Contour

Compares the contours in the region with the contours in

the same region on the reference object. The better the two

contours correspond, the greater is the matching score for

the inspections.

Pattern (I40)

Compares each pixel’s value in the region with the

corresponding pixel value in the reference image. The better

the pixels correspond, the greater is the matching score for

the inspections.

<4 px

When teaching an Inspector which has not previously been

configured, the resulting reference object will have an object

locator that covers the entire field of view.

1. Place an object in front of the Inspector and connect in2

to +24 V.

After about 3 seconds the Function LED starts to flash.

3. Click Teach reference object.

The Inspector captures a reference image of the object

and displays it.

3. Find the field of view with the help of for example a pen.

When the Inspector detects movements in the field of

view, the Function LED changes color to blue.

5. Add detailed inspection over the parts of the object to be

inspected.

4. Disconnect in2 from the power.

The Inspector will now use the latest captured image as

reference image.

6. Test the inspection in the Live image and adjust the

settings if necessary.

5. The Inspector will then automatically switch to Run mode

and start inspecting

When the inspections are accurate enough, switch to Run to

put the Inspector in operation. When asked, you should save

the settings in the Inspector’s flash memory to assure that

they will be remembered if the power should be disconnected.

1. Mount the Inspector at an appropriate distance from the

objects to be inspected.

SOPAS ET is the PC application that is used for monitoring and

configuring the Inspector. It can be installed on any PC, and

then be used for accessing any Inspector that is connected to

the same network as the PC.

To connect to an Inspector from SOPAS ET.

1. Make sure that the Inspector is powered, and connected

to the PC or to the same network as the PC.

2. Start

SOPAS ET

.

3. In the

Device search

pane, double-click on the Inspector in

the list of available devices.

An object locator is used when teaching the Inspector to

recognise the objects to inspect. Each reference object can

not have more than one object locator.

The Inspector locates an object by recognising the contours

of it. The contours that are used are highlighted in green in

SOPAS ET.

b

Adjust the amount of contours to learn with the

Edge

strength

slider on the

Object locator

tab.

b

Adjust the size, location, shape, and rotation of the object

locator so that it covers the object properly. Use masks

to mask out areas that normally varies on the object, for

example if they have different labels .

OK

Enough amount

of learned

contours

Bad

Too few

contours

Bad

Too many con-

tours, as well as

contours on the

background

Match Settings

b

If objects are never rotated, deselect

Allow rotation

to

improve both robustness and speed.

b

To verify that objects are not rotated more than a small

amount, select

Allow rotation

and set the max rotation to a

small amount.

b

If objects are always of the same size and at the same

distance from the Inspector, deselect

Allow scaled objects

to

improve both robustness and speed.

An Inspector with ring

light

may need to be

mounted at a small angle

to avoid too much reflexes.

An Inspector with Dome

light

should be aligned

with the objects, at a

distance of approximately

50 mm to get optimal

effect of the dome lighting.

2. Connect the Ethernet connector on the Inspector to a

network, or directly to an Ethernet connector on a PC.

4. If necessary, adjust the size and location of the object

locator, and the amount of highlighted contours.

b

Bright contours are more important than dim contours.

b

Avoid highlighting contours outside the object.

b

It is not necessary to get bright contours everywhere on

the important contours.

Note

:

The Edge strength setting for Edge pixel

counter and Contour inspections is common

for all inspections of these types for a reference

object.

The Inspector

first locates the

object...

... and then inspects

details on the found

object.

Detailed

inspection

Object

locator

b

High-speed object inspection

b

Robust pattern match algorithm to locate objects indepen-

dent of position, rotation and scale

b

Multi-feature inspections /object

b

Multi-reference object teaching

b

Easy-to-use configuration in PC

b

Emulator, log, statistics and record for production control

b

Industrial Ethernet for monitoring over network

b

Exchangeable lens (Flex)

b

Outputs by logical expressions (I20, I40)

b

Input and output extensions via I/O box (I20, I40)

b

Store inspected images to remote FTP server (I40)

b

Provide detailed inspection results over EtherNet/IP (I40)

b

Live image/log/statistics view and reference object change

via external Viewer

The Inspector inspects objects in the following way:

b

First, it locates the object in the view.

b

After that, it inspects details on the object to find out

whether the object is OK or not.

All passed

Detail failed

Not located

On

On

On

Off

Each inspection gives one of the following results:

Not located

The object was not located, or a detailed

inspection was out of view

Detail failed

The object was located but at least one of the

detailed inspections failed.

All passed

The object was located and all detailed inspec-

tions passed as well.

The Inspector provides the inspection result in the following

ways, depending on the model:

I10

3 fixed built-in digital

outputs

out1 – Not located

out2 – Detail failed

out3 – All passed

I20,

I40

3 built-in digital outputs

16 additional digital

outputs with I/O exten-

sion box

Configurable, using

Outputs by logical

expressions

(Default same as I10)

I40

EtherNet/IP

Detailed inspection

results

1. Switch the Inspector to Edit mode by clicking

Edit

in the

main view.

2. Place an object in front of the Inspector, and adjust focus

and exposure so that the Live image is sharp and bright.

2. Adjust focus by turning the focus screw.

The faster the Function LED flashes, the better the focus.

±4 px

The device now appears in the

New Project

pane. Double-click

on the device to open the device window and start the

configuration.

b

If the Inspector is not listed in the

Device search

pane, click

Search settings

to fine tune the search criteria.

b

If the connection to the device is not working, change the

IP settings of the device via the edit icon on the device tile.

Also make sure that the required SOPAS Device Driver (SDD)

is installed: Select the

Device catalog

tab and add the SDD via

the

Configuration

button.

For more information about the connection, see the online

help.

3. If the input or output signals are used, or if an external

lighting will be used, connect those devices to the

Inspector’s Power connector (

B

).

Note:

Make sure that the loose ends of the I/O cable

are separated before powering the Inspector.

4. Connect the Inspector to a 24 V DC power supply (

B

).

5. If a PC should be used for configuring the Inspector,

install the configuration software SOPAS ET v 3.x. SOPAS

ET is available for download, free of charge, from the

Software finder at www.sick.com.

SICK uses standard IP

technology for its products, e.g. IO Link,

industrial PCs. The focus here is on providing availability of

products and services.

S

ICK always assumes that the integrity and confidentiality of

data and rights involved in the use of the above-mentioned

products are ensured by customers themselves.

In all cases, the appropriate security measures, e.g. network

separation, firewalls, antivirus protection, patch management,

etc., are always implemented by customers themselves,

according to the situation.

Disclaimer

EN