Product description

FLOWSIC200 · Operating Instructions · 8013271/1CJ9/V2-0/2022-01 · © SICK Engineering GmbH

27

2.3

Computations

2.3.1

Flow velocity calibration

When the measured velocity does not agree with the mean value of the flow velocity in the

entire tunnel cross-section, the FLOWSIC200 can be calibrated by a network measurement

with a comparison measuring system. Regression coefficients Cv2, Cv1 and Cv0 are

determined from the measured values of the two measuring systems, which are entered

into the FLOWSIC200 during parameterization (

). The device then calculates

the calibrated flow velocity v from measured value x of the FLOWSIC200 according to the

following formula:

v = Cv2

·

x

²

+ Cv1

·

x + Cv0

If no calibration is required, Cv2, Cv0 = 0, Cv1 = 1 (default factory setting). The value x then

corresponds to the representative velocity.

2.3.2

Temperature calibration

The calibration of the temperature measurement with the FLOWSIC200 can be done by a

comparison measurement with a separate temperature sensor (e.g. Pt100), but is

generally not necessary, since the active measuring distance can be determined extremely

accurately (

±

1 cm) (see formula 2.6,

2.3.3

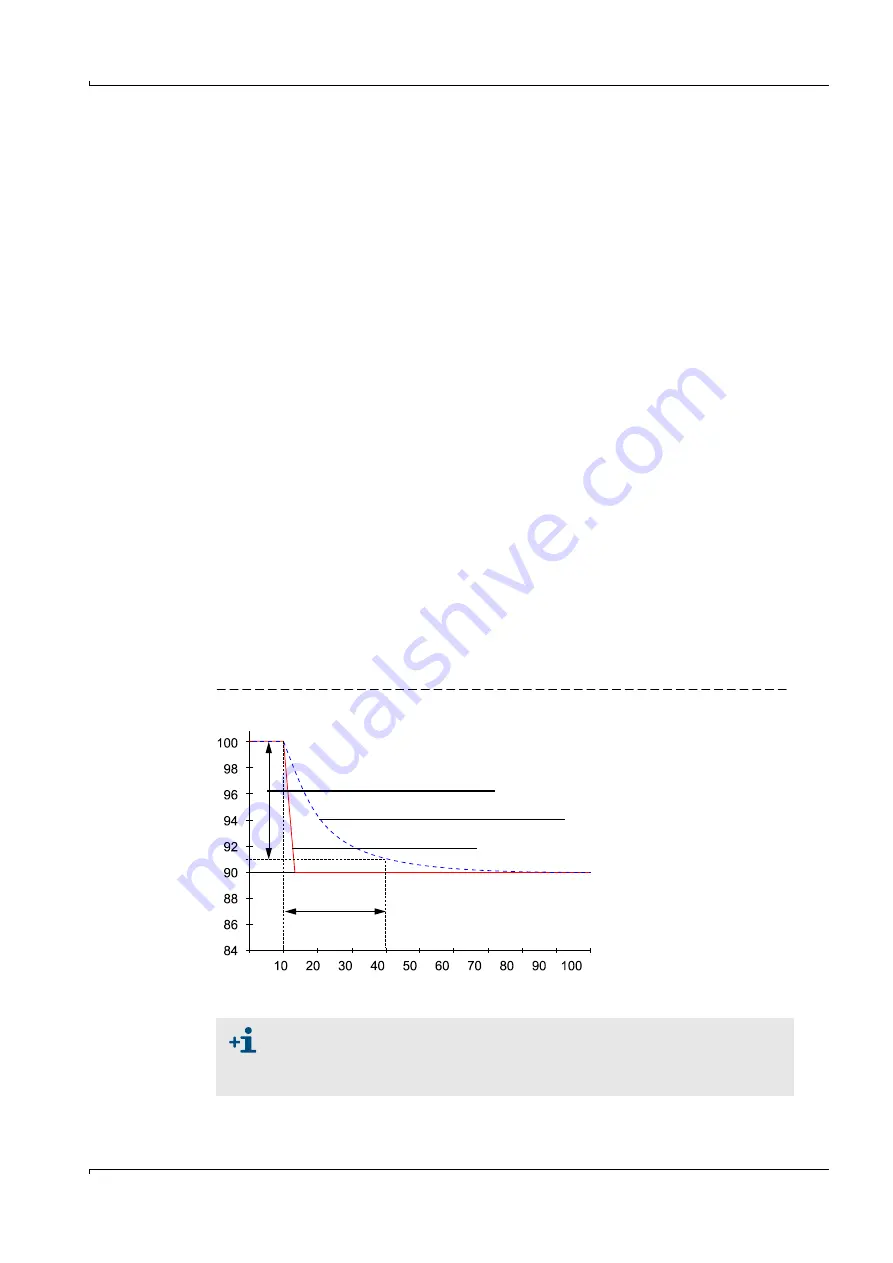

Response time

The response time is the time taken by the measuring device to reach 90% of the end value

after a sudden change in the measured value (

).

The response time can be set to any value in the range 1...300 (typical: 60 ... 90 s). Setting

a higher response time provides better attenuation of transient fluctuations in the

measured value and interference to produce a “smoother” output signal.

There is a separate response time for the measurement of flow velocity and air temperature

respectively.

Fig. 11

Response time

Measured value

90% of the peak

Measured value with response time

Process change

t in s

Response time

The response time should be regarded as a guide value. If the signal quality of

the ultrasonic pulses is poor, the FLOWSIC200 requires more measured values

for an output signal of the same accuracy. As a result, the response time is

higher, within certain limits, than the set time.