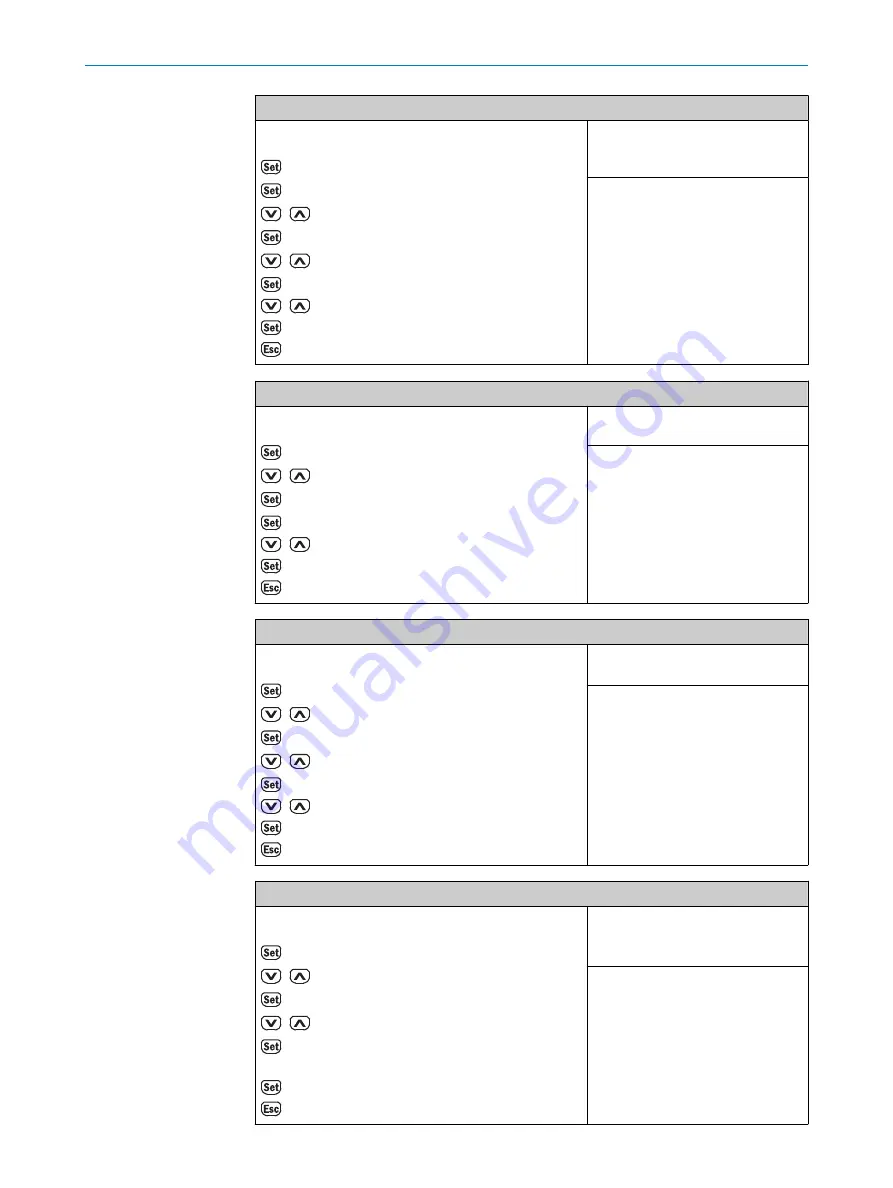

Manually switch the logic for Q

1

to “Low Active”

Operating example or steps:

RUN mode

→ Q

1

Output

→ ModeQ

1

/

to → Manual Q

1

→ Q

1

/

to → Q

1

Logic

→ High Active

/

to → Low Active

→ Saved

to → RUN mode

Necessary default settings:

Factory setting or mode Q

1

= DtO (1

point)

Factory setting:

High Active

For the output function Q

2

configure and activate /Q

a

through switching

Operating example or steps:

RUN mode

→ Q

1

Output

/

to → Q

2

Output

→ Function Q

2

/Q

a

→ 4 - 20 mA

/

to → Switching

→ Saved

to → RUN mode

Necessary default settings:

-

Factory setting:

4 - 20 mA

Select and activate the DtO (1point) switching mode for Q

2

Operating example or steps:

RUN mode

→ Q

1

Output

/

to → Q

2

Output

→ Function Q

2

/Q

a

/

to → ModeQ

2

→ ...

/

to → DtO (1point)

→ Saved

to → RUN mode

Necessary default settings:

Function Q

2

/Q

a

= Switching

Factory setting:

-

Teach in the current distance as a single or DtO switching point for Q

2

in the menu

Operating example or steps:

RUN mode

→ Q

1

Output

/

to → Q

2

Output

→ Function Q

2

/Q

a

/

to → Teach Q

2

→ Q

2

Position object

→ Saved

to → RUN mode

Necessary default settings:

Function Q

2

/Q

a

= Switching

ModeQ

2

= DtO (1point)

Factory setting:

-

6

OPERATION

26

O P E R A T I N G I N S T R U C T I O N S | DT50-2 Pro

8017154/1AVV/2021-03-24 | SICK

Subject to change without notice