33(77)

2.3.14 Reduction Gear

Picture 2-13: Reduction Gear

1. Installation and Use

For connection of high speed shaft and other parts, hammering is not

allowed. Users can rotate bolts into shaft-end holes and press fastenings.

After install reduction gear, rotate it manually to ensure smooth rotation.

Without loading condition, operate device for 2 hours. If you find uneven

sounds, overheat and oil leakage, please shut it down and contact Shini

Company.

During installing torque arm, make point of connection being vertical with

output shaft axis, deviation is

±

5

o

.

2. Lubrication

Use VG46 gear oil to lubricate reduction gear, do not use additives

containing graphite or molybdenum disulfide. After first oil filling, run the

machine for 2 hours then replace oil. Replace the oil after 6 months or 2500

hours running.

Summary of Contents for SGS-6080S

Page 1: ...SGS S Single shaft Shredders Date May 2014 Version Ver B English...

Page 2: ......

Page 8: ...8 77...

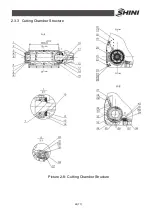

Page 24: ...24 77 2 3 3 Cutting Chamber Structure Picture 2 8 Cutting Chamber Structure...

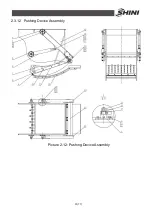

Page 31: ...31 77 2 3 12 Pushing Device Assembly Picture 2 12 Pushing Device Assembly...

Page 37: ...37 77 2 4 Wiring Diagram 2 4 1 Wiring Diagram Picture 2 16 Wiring Diagram...

Page 38: ...38 77 2 4 2 Control Wiring Diagram Picture 2 17 Control Wiring Diagram 1...

Page 39: ...39 77 Picture 2 18 Control Wiring Diagram 2...

Page 40: ...40 77 2 4 3 Electrical Components Layout Picture 2 19 Electrical Components Layout 1...

Page 41: ...41 77 Picture 2 20 Electrical Components Layout 2...