- 26 -

8-5

.

.

.

.

Welding Work

Warning: Suffocation from Welding Fume

•

Always be sure to wear a fume-proof mask when welding as the fumes

generated during welding include harmful gases and dust. Also be

careful that the wind direction is not such that it will cause fumes to be

inhaled and always operate the equipment in a well-ventilated area.

Warning: Fire

•

Keep any ignitable items (such as fuel, gas and paint) or inflammable

items away from the work area due to the scattering of weld spatter that

occurs during welding.

Warning: Electromagnetic Interference

•

Persons using a heart pacemaker are not allowed near the welder or

welding work area while welding is being performed without the

permission of a doctor. The welder generates a magnetic field while

energized that can negatively affect pacemaker operation.

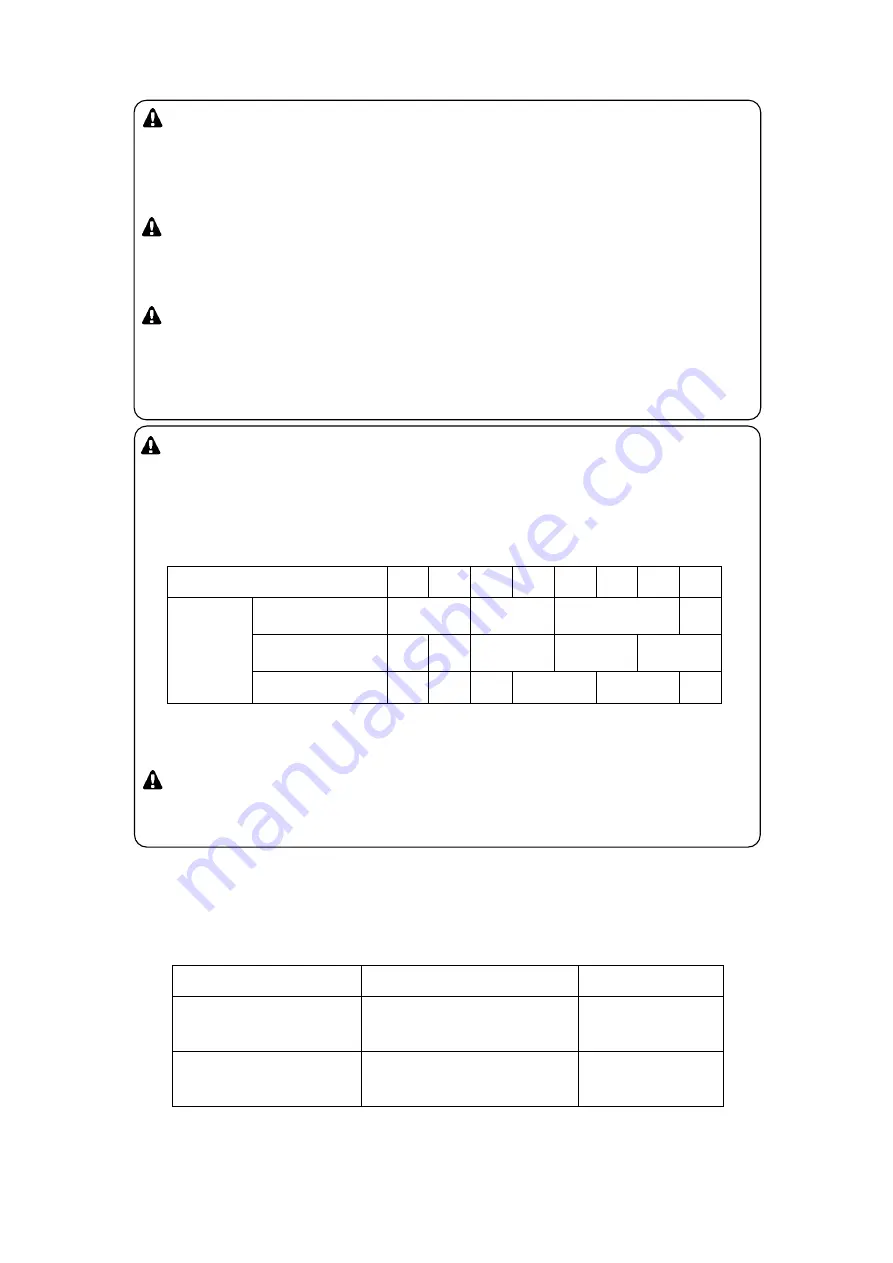

Caution: Injury to Eyes and Skin

•

Always be sure to wear arc-proof glasses (refer to the table below),

clothes that completely cover the skin and other protective gear when

welding to protect the eyes and skin from harmful light rays generated

during welding.

Standards for Arc-Proof Glasses

(

Japanese Industrial Standard

)

Filter No.

7

8

9

10

11

12

13

14

Shielded Metal

Arc Welding

35-75

76-200

201-400

400

Scratch Start TIG

Welding

-

-

100 or less 100-300

301-400

Weld

Current

(A)

Gouging

-

-

-

126-225

226-350

-

•

Always be sure to wear leather gloves, apron, shoe covers, arc-proof

glasses (face shield), safety shoes, hard hat and long-sleeve clothing to

protect against the scattering of weld spatter that occurs during welding.

Caution: Electric Shock

•

If wearing gloves, be sure to always wear gloves with dry insulation

properties. Do not wear gloves that are damaged or wet.

You can select a weld mode with the type of welding being performed. Select a

weld mode by referring to the recommended modes in the table below.

Weld Modes Table (Recommended)

Mode Name

Applications

Welding Position

DROOP-STANDARD

/

GOUGING

Welding of pipes, tanks and

similar items

Gouging

Vertical

and

Upward

CC-CELLULOSE

/

SCRATCH START TIG

Welding of structures and

finishing welding

TIG welding

Horizontal

and

Downward

Summary of Contents for DGW400DM-C

Page 2: ......

Page 44: ...41 14 Engine Wiring Diagram...

Page 45: ...42 15 Generator Wiring Diagram...

Page 46: ...43...

Page 47: ...44...

Page 48: ...45 2013...